Throttle valve port performance test device

A test device and throttle valve technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problem of inability to test the dynamic characteristics of the valve core, oil flow, cavitation and other phenomena that cannot be observed, The structure of the test device is complex and other problems, and the structural optimization design is efficient and reliable, the signal is rich, and the effect of scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

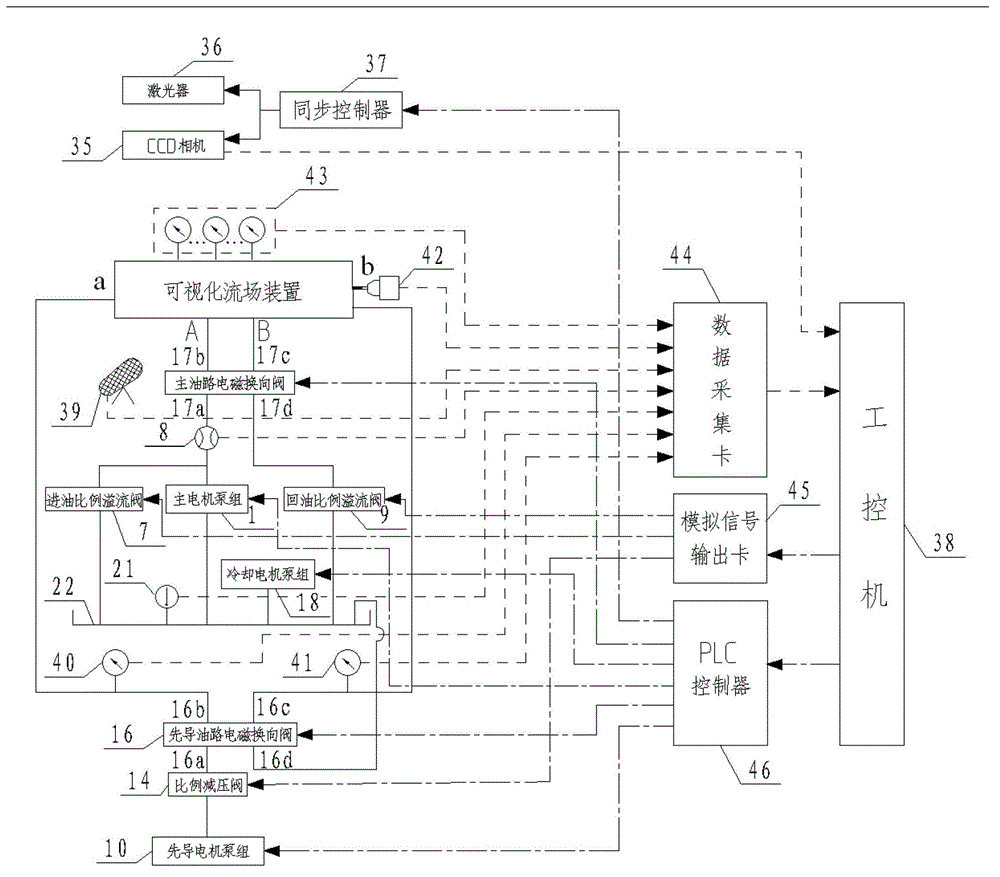

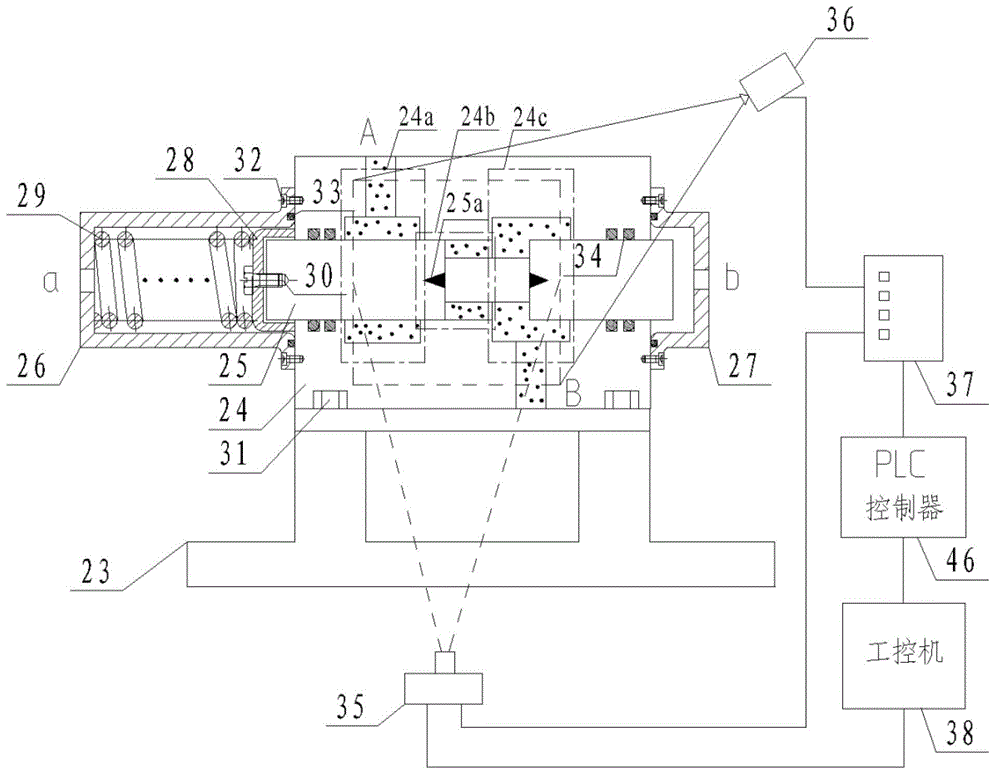

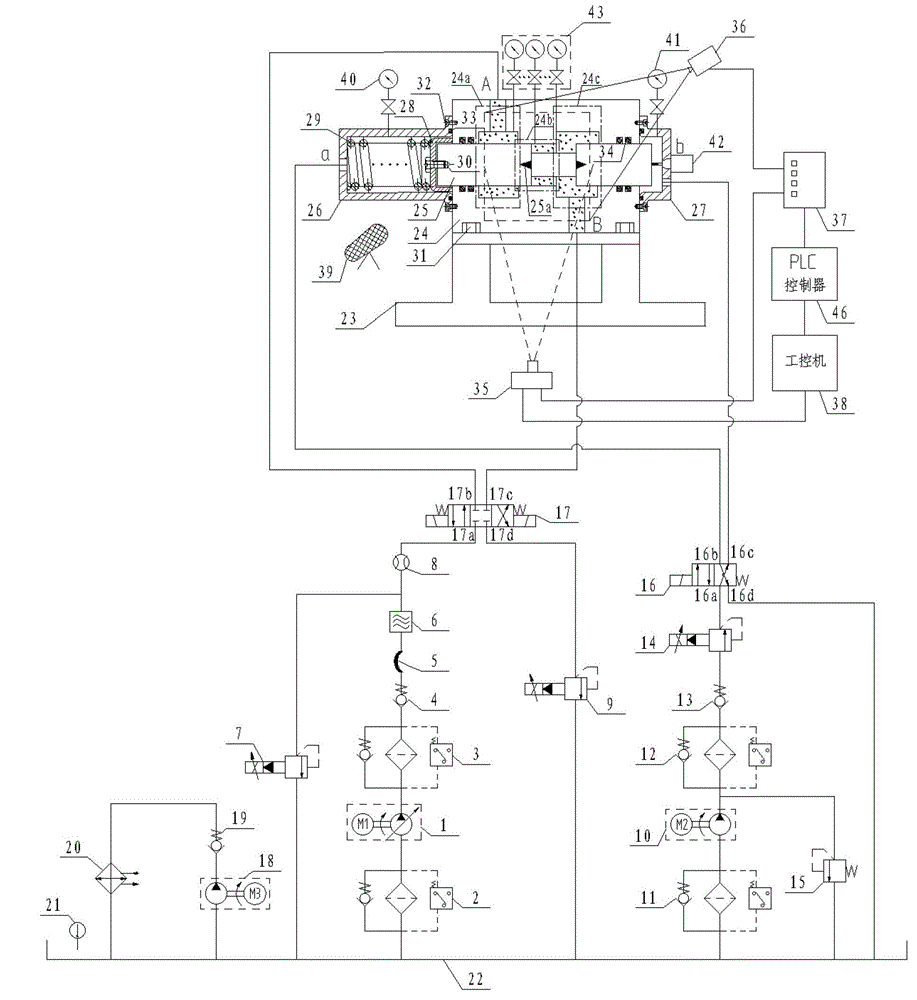

[0037] Figure 1~4 Middle: main motor pump unit 1, main oil circuit suction filter 2, main oil circuit pressure filter 3, main oil circuit check valve 4, hose 5, filter 6, oil inlet proportional relief valve 7, flow sensor 8. Oil return proportional relief valve 9, pilot motor pump unit 10, pilot oil circuit suction filter 11, pilot oil circuit pressure filter 12, pilot oil circuit check valve 13, proportional pressure reducing valve 14, overflow valve 15 , pilot oil circuit electromagnetic reversing valve 16, pilot oil circuit electromagnetic reversing valve port one 16a, pilot oil circuit electromagnetic reversing valve port two 16b, pilot oil circuit electromagnetic reversing valve port three 16c, pilot oil circuit electromagnetic reversing valve port three 16c, pilot oil circuit electromagnetic reversing valve Port 4 16d, main oil circuit electromagnetic directional valve 17, main oil circuit electromagnetic directional valve port 1 17a, main oil circuit electromagnetic di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com