Shell body joint structure and jointing method thereof

A joint structure and joint method technology, applied in the direction of base/housing, electrical equipment housing/cabinet/drawer, electrical components, etc., can solve the problem of affecting the electrical characteristics of electronic devices or their accessories, electrical leakage, and insufficient creepage distance of electrical clearances And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

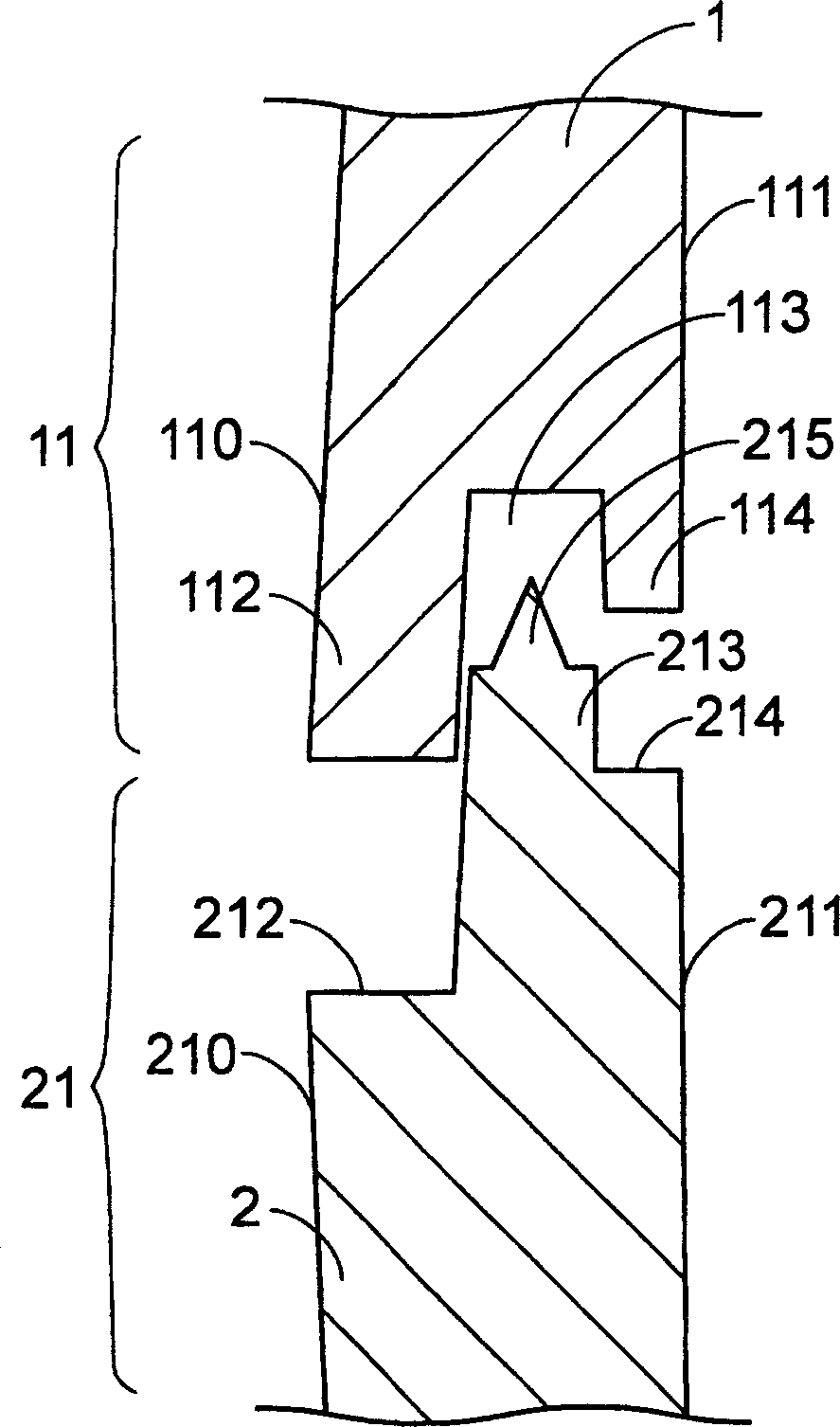

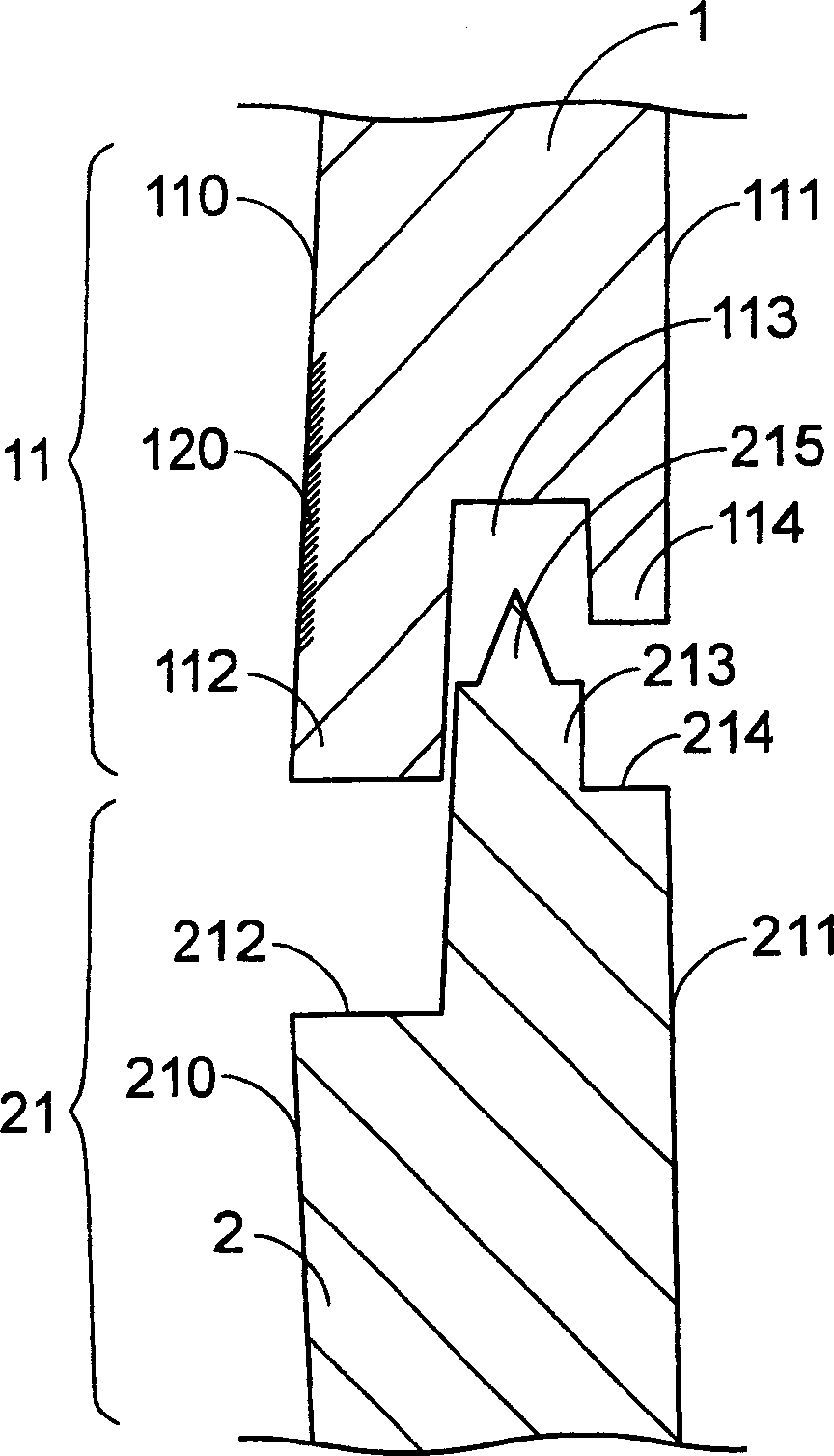

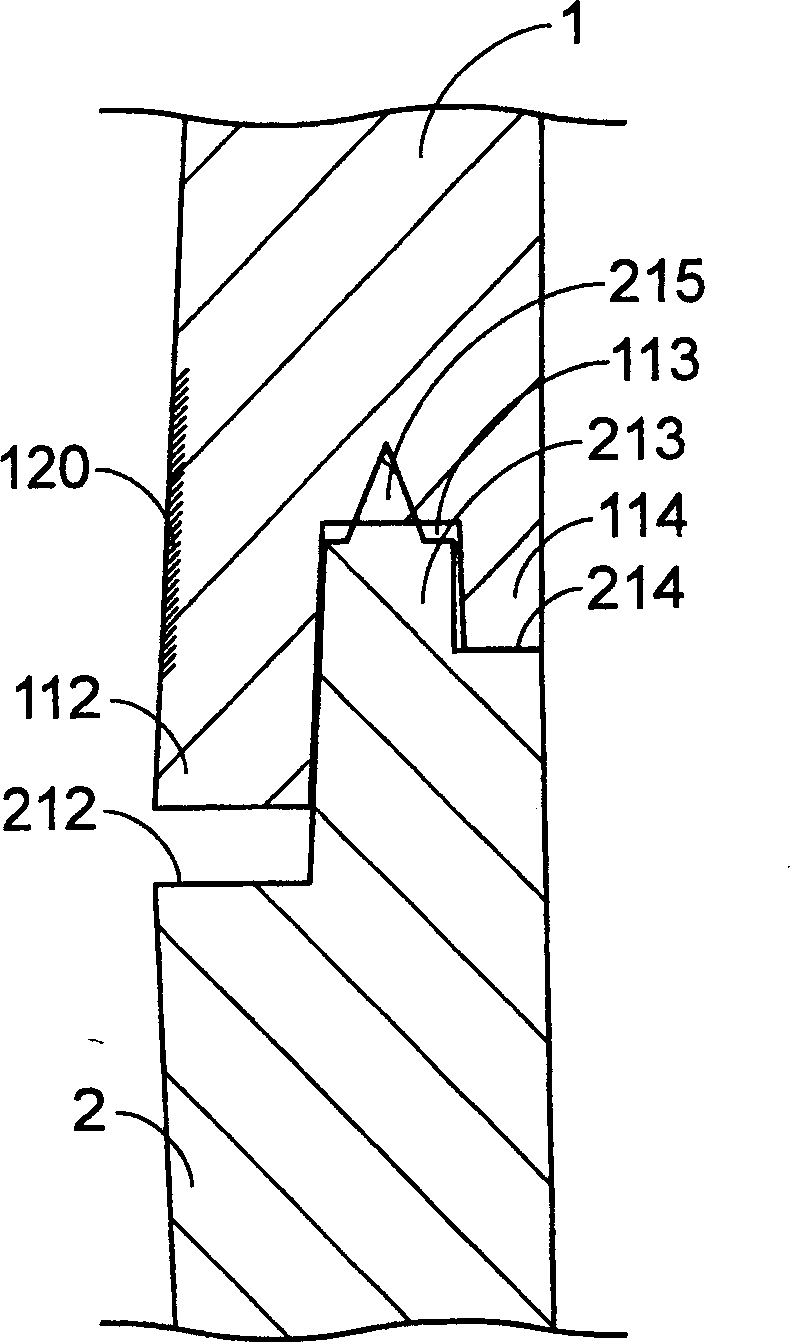

[0046] see image 3 , which is a schematic diagram showing the joint structure of the housing in a preferred embodiment of the present invention. Such as image 3 As shown, the housing joint structure of the present invention is composed of an upper housing 3 and a lower housing 4 engaged with each other. The upper casing 3 has a joint portion 31, which sequentially forms a first concave portion 312, a first convex portion 313, a first groove 314 and a first Two convex parts 315. In addition, the lower case 4 also has a joint portion 41 , and the joint portion 41 forms a first concave portion 412 , a first convex portion 413 and a second concave portion 414 sequentially from the outer surface 410 to the inner surface 411 . In this embodiment, the first concave portion 312 and the first convex portion 313 of the upper case 3 are opposite to the first concave portion 412 of the lower case 4 , and their widths are approximately equal. In addition, the first groove 314 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com