Non-routine reactor shutdown method

A reaction and reaction zone technology, applied in chemical instruments and methods, carboxylate preparation, carbon-based compound preparation, etc., can solve problems such as reactor fire or explosion, increased operational complexity, and reactor leakage reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

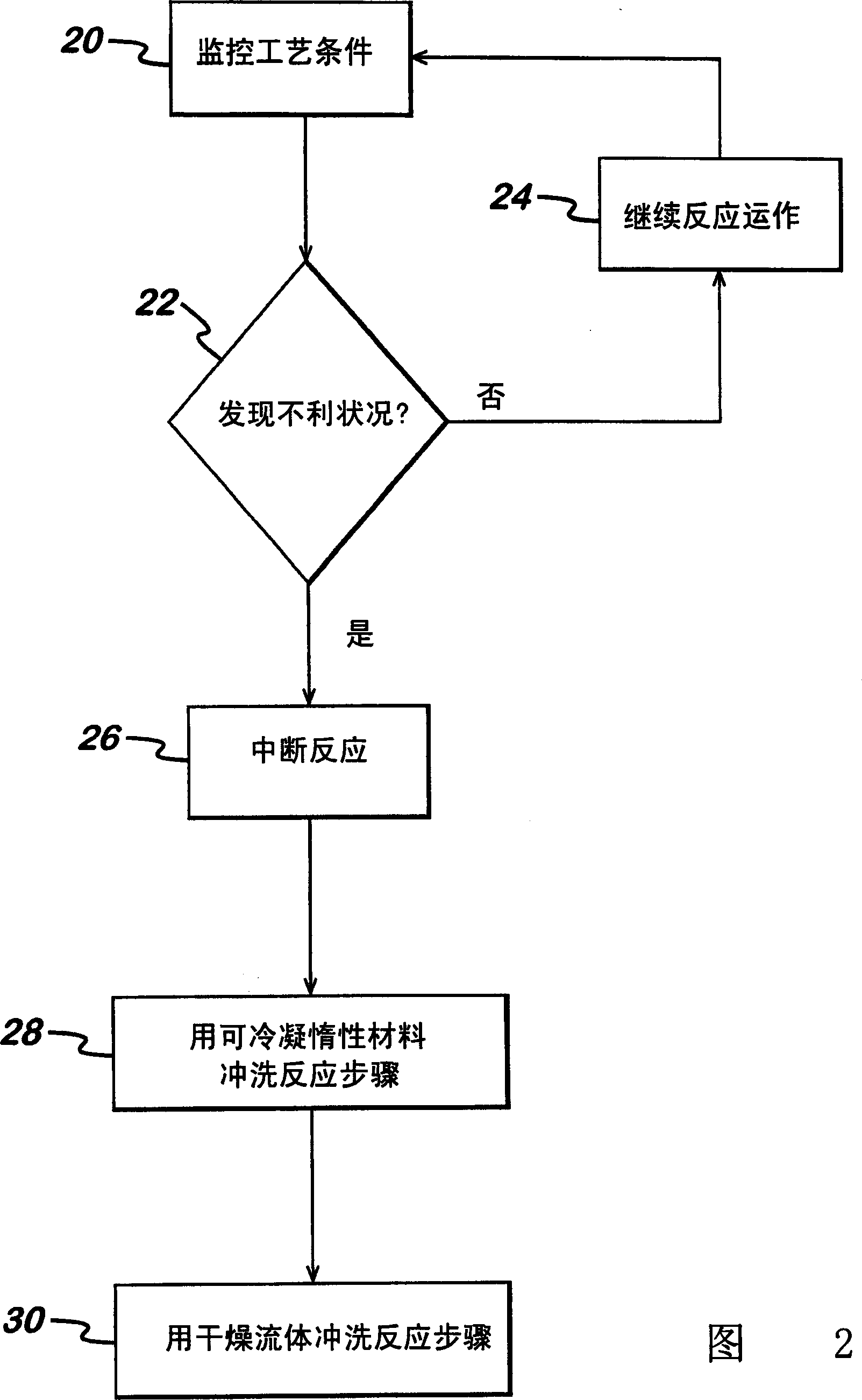

[0059] In a non-limiting embodiment of the method of the present invention, a series of unfavorable reaction process conditions for the partial catalytic oxidation process for the production of acrylic acid are enumerated. During the reaction of this example, a plurality of contacting shell-and-tube reactors were continuously supplied with a total feed of propylene, air and inert material (steam), and one or more commercially available molybdenum-oxidized In the presence of a material MMO catalyst, under sufficient process conditions to oxidize propylene to acrolein and acrylic acid. Listed identified adverse reaction process conditions include, but are not limited to:

[0060] · Flammable reactor feed mixture

[0061] · High reactor pressure

[0062] ·Reaction process leakage

[0063] Runaway reaction / rapid catalyst temperature rise

[0064] · High catalyst temperature

[0065] ·Low catalyst temperature

[0066] Incorrect reactant to oxidant feed ratio

[0067] Incorre...

Embodiment 2

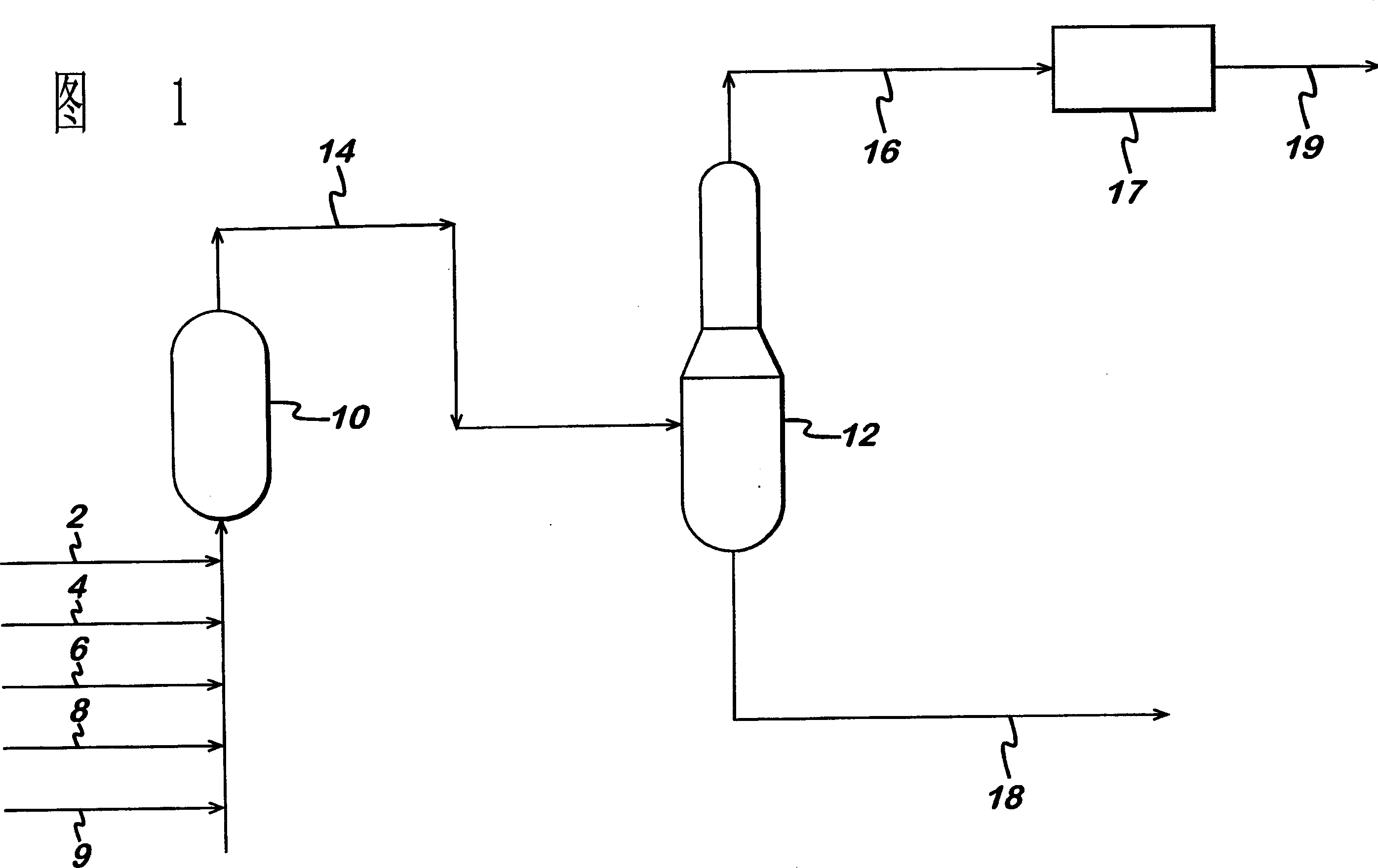

[0081] In one non-limiting embodiment of the invention, the reaction process occurs as part of the chemical process for producing acrylic acid. The chemical process consists of two shell-and-tube reactors connected in series with an auxiliary intercooler (herein referred to as "tandem reactors") with an absorber downstream of the series reactor and receiving heat from the absorber overhead stream. oxidizer. Each shell-and-tube reactor vessel consisted of about 10,000 tubes with a diameter of 1.5" (37.5 mm) packed with a commercially available molybdenum-oxide (MMO) oxide catalyst. The reactors in series and their auxiliary tubes The volume is approximately 5557 cubic feet (157 cubic meters).The process of this example also includes a computer-based control system capable of sensing adverse conditions in the chemical process.

[0082] Under normal operating circumstances, a total feed of propylene, air and steam is continuously provided to the reaction process under process co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com