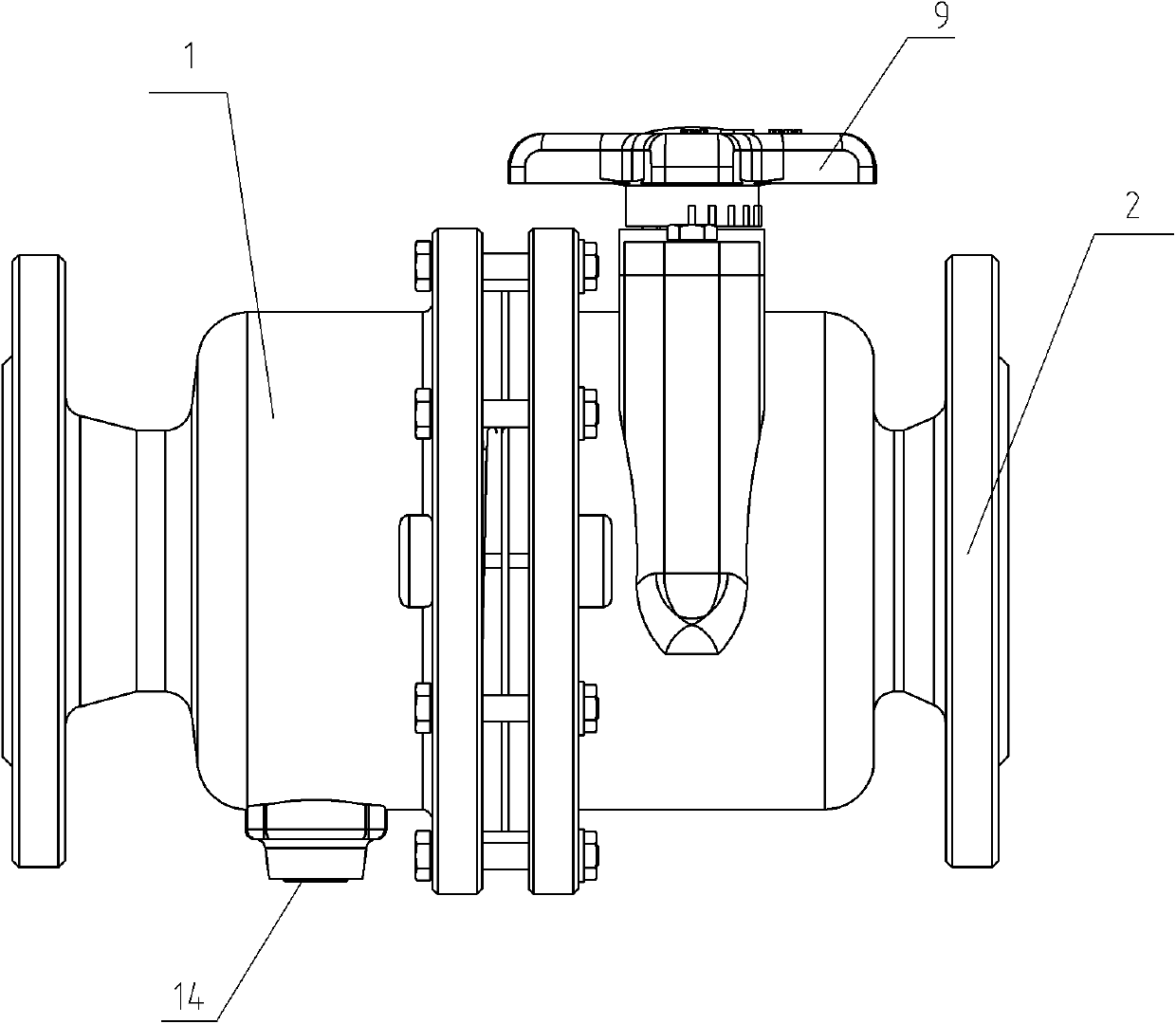

Axial flow type flow quantity control valve with dual filtering function

A flow control valve, double filtration technology, applied in the direction of filtration and separation, valve absorbing fluid energy device, sliding valve, etc., can solve problems such as easy to cause noise, large valve disc impact, noise, etc., to prevent pollution and clean water. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

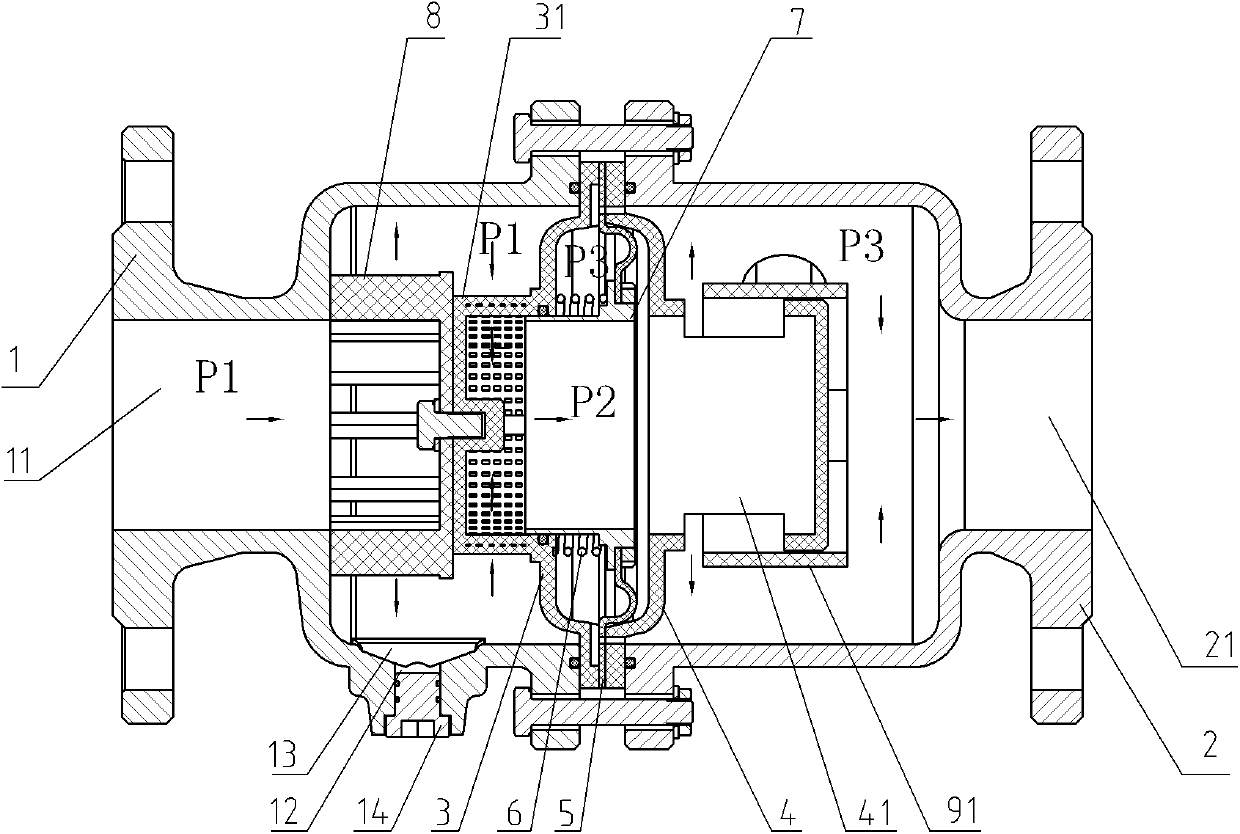

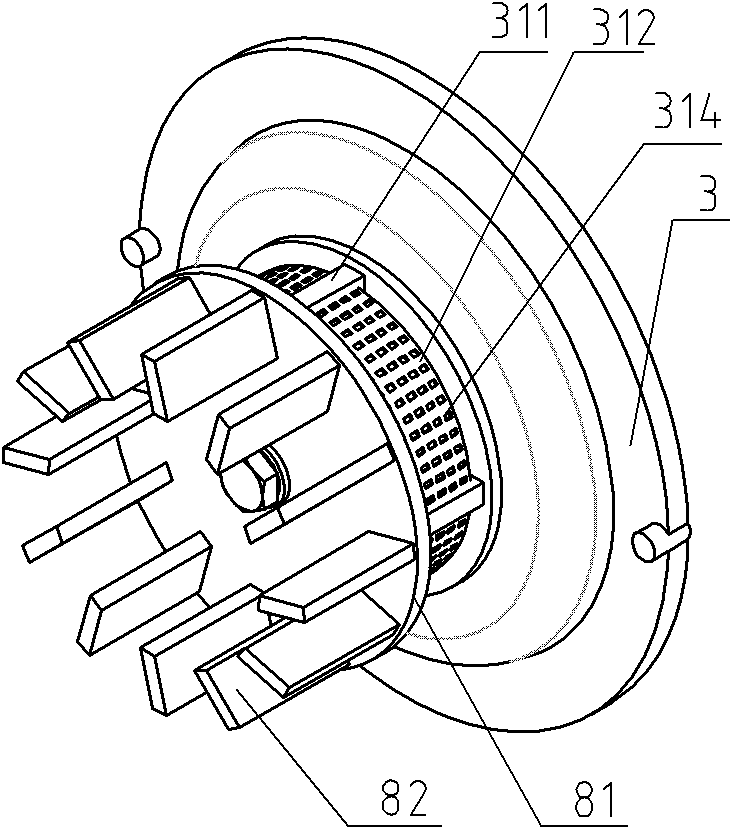

[0031] The invention provides an axial flow control valve with double filtering function, which includes a valve body and a valve frame fixed in the valve body to adjust the flow rate of the control valve. The valve body includes a left valve body with an inlet and an outlet. The right valve body of the orifice, the left valve body is provided with a spoiler, the spoiler is located between the inlet and the valve frame, and the valve frame is provided with a filter hole on the side facing the spoiler, and the left valve body is provided with Sewage outlet that can be opened and closed. During the working process, the fluid flowing in from the upper inlet of the left valve body will decelerate when it flows through the spoiler. When the flow velocity decreases, the large impurities in the fluid will sink due to gravity; when flowing through the valve frame, The filter hole acts as a secondary filter for filtering fine impurities, and finally the double-filtered fluid flows out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com