Hydrocyclone with novel outlet structure

A technology of hydrocyclone and outlet structure, which is applied in the direction of swirl devices and devices whose axial direction of swirl can be reversed, etc., can solve the problem of low separation efficiency of small pressure drop hydrocyclones, and save working space , Reduce pressure drop, reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

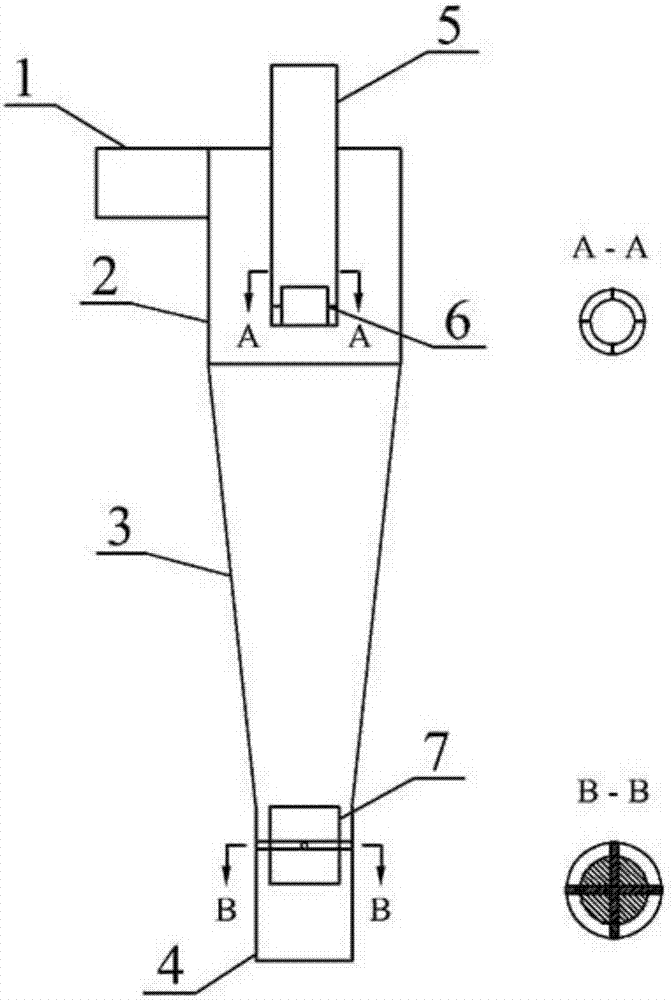

[0014] In this embodiment, the hydrocyclone overflow pipe 5 and the cylindrical section 2, the cylindrical section 2 and the conical section 3, and the conical section 3 and the underflow pipe 4 are all connected by flanges. A solid cylinder 7 is fixed inside the underflow pipe 4, and a sleeve 6 is fixed at the lower end of the overflow pipe 5 through four sheets. The liquid-solid slurry to be separated is driven horizontally and tangentially into the cylindrical section 2 of the hydrocyclone by the slurry pump through the feed pipe 1. Through the action of centrifugal force, the solid particles are thrown to the side wall as the heavy phase and flow along the side wall. Make a spiral movement downwards, discharge through the annular gap between the solid cylinder 7 and the bottom flow pipe 4, and the cleaning product flows out from the overflow pipe 5 as the light phase.

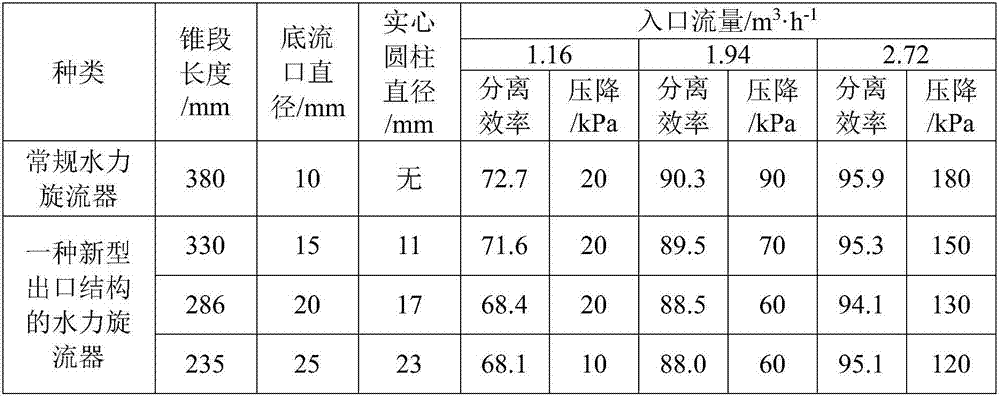

[0015] The following is a comparison of the experimental process and results of a conventional hydrocycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com