A well completion method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

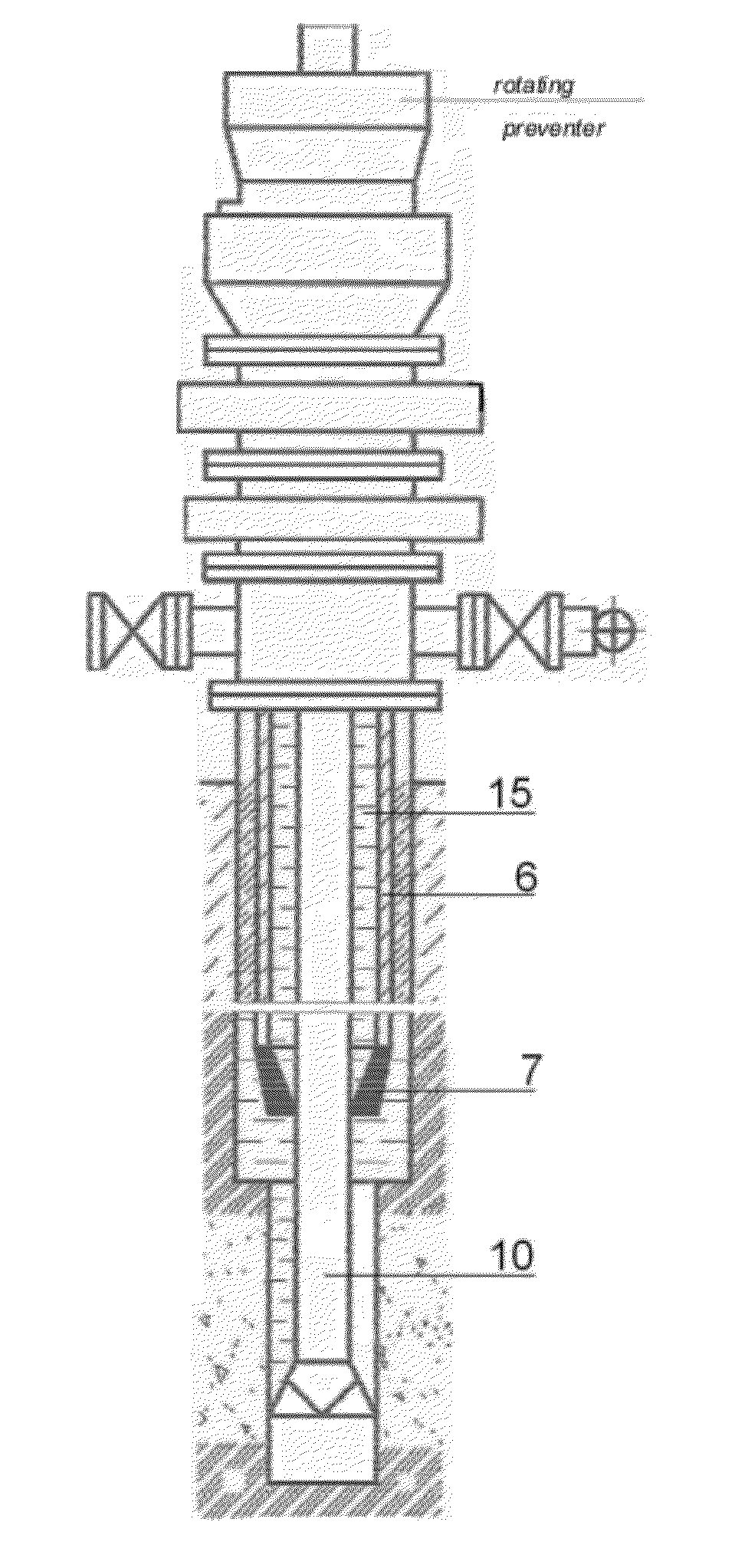

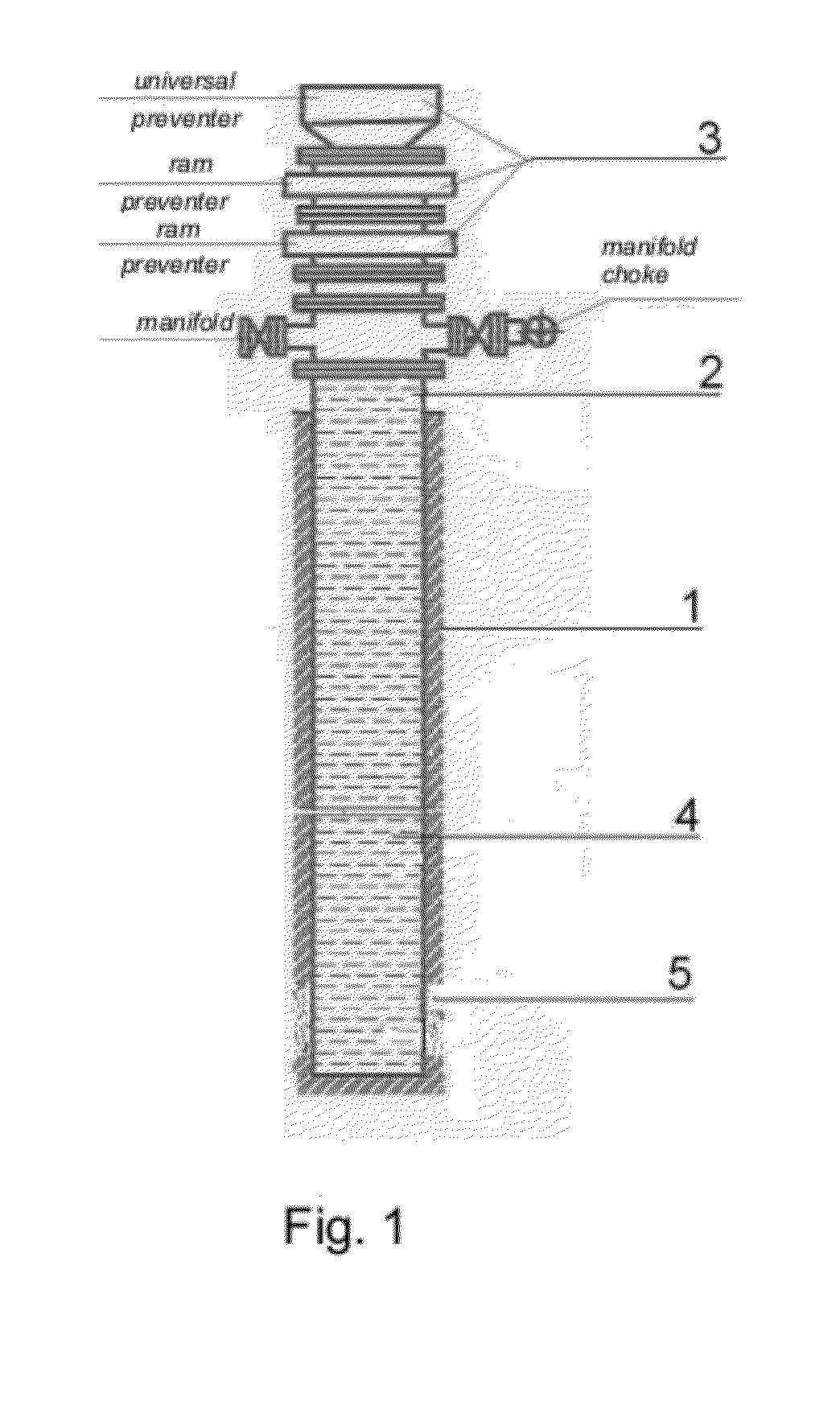

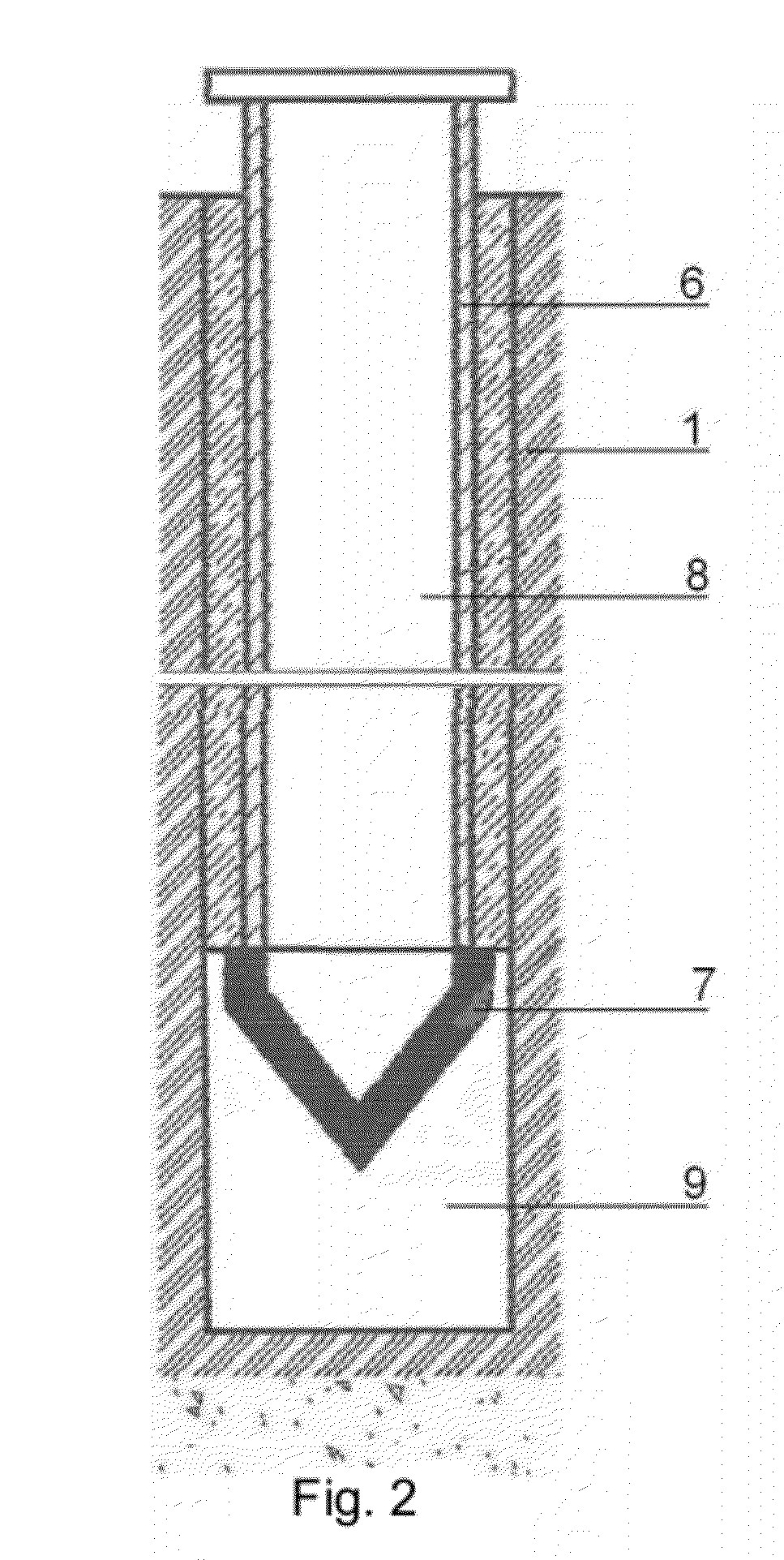

[0039]In FIG. 1-4 represented:[0040]Well—1.[0041]Opening—2[0042]Blowout preventer—3.[0043]Washer fluid—4.[0044]Producing formation—5.[0045]producing string—6.[0046]Sealing device—7.[0047]Upper cavity (well 1)—8.[0048]Lower cavity (well 1)—9.[0049]Downhole equipment (drill string) with check valve—10.[0050]Housing (device 7)—11.[0051]Thread (on housing 11)—12.[0052]Bearing—13.[0053]Sealing in the form of a collet—14.[0054]Washer fluid—15.

[0055]The well (1) with the opening (2) is equipped for operations on the primary development of the producing formation (5). The well (1) is filled with the washer fluid (4).

[0056]Blowout preventer (3) in the form of the universal and ram-type preventers (FIG. 1) is installed on the opening (2) to prevent blowouts of formation fluids, and the manifold with the choke (FIG. 1) for adjustment of the intensity of washer fluid flow from the well (1) during process operation on the well (1) deepening.

[0057]The rotating preventer (FIG. 3) is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com