Aspirator for crankcase ventilation and vacuum generation

a technology for vacuum generation and aspirators, which is applied in the field of aspirators, can solve the problems of low vacuum in the intake manifold, unsatisfactory leakage of oil pan gaskets and crankcase seals, and inability to match intake manifold vacuum characteristics, so as to simplify the control of the pcv system and reduce manufacturing and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

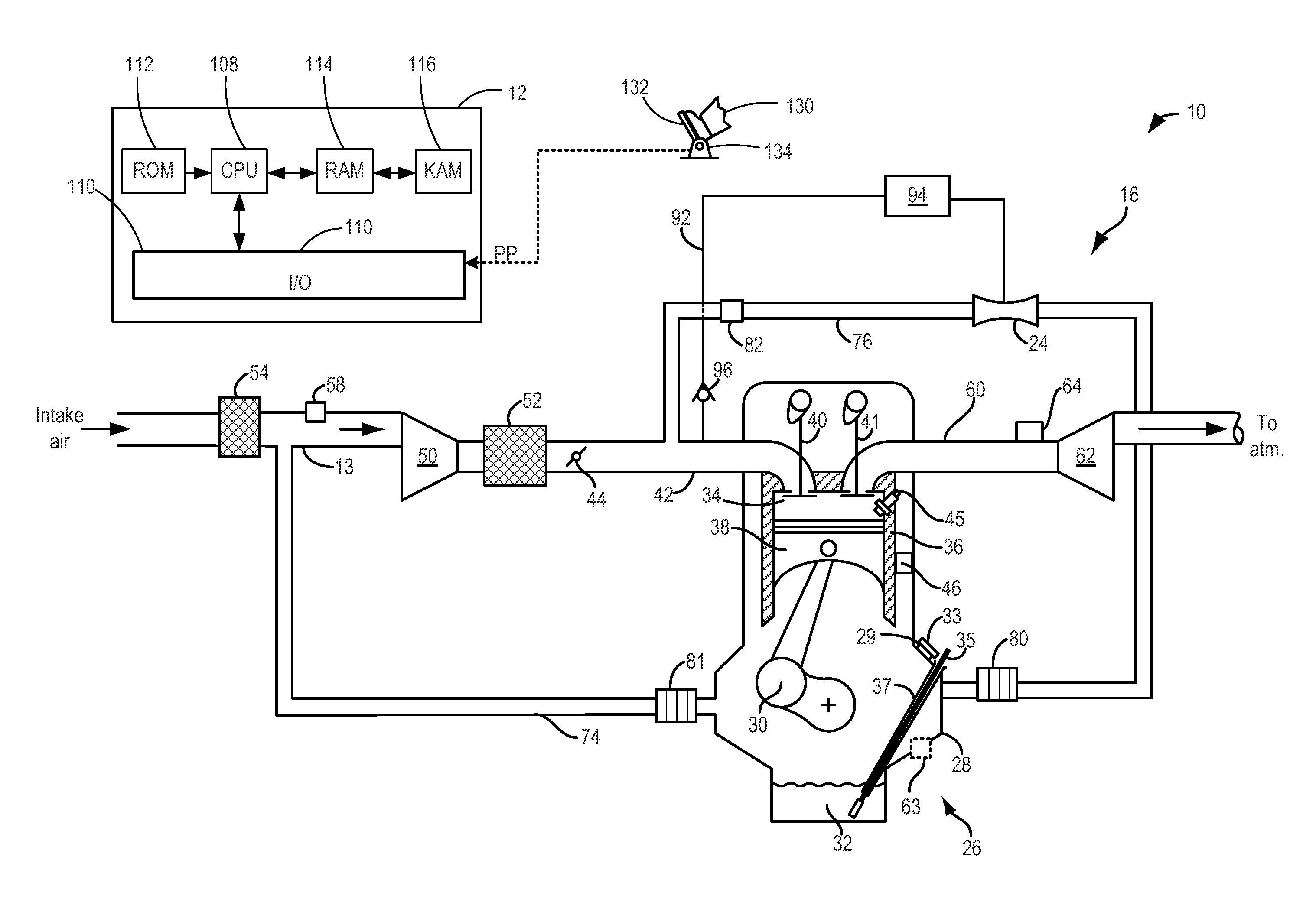

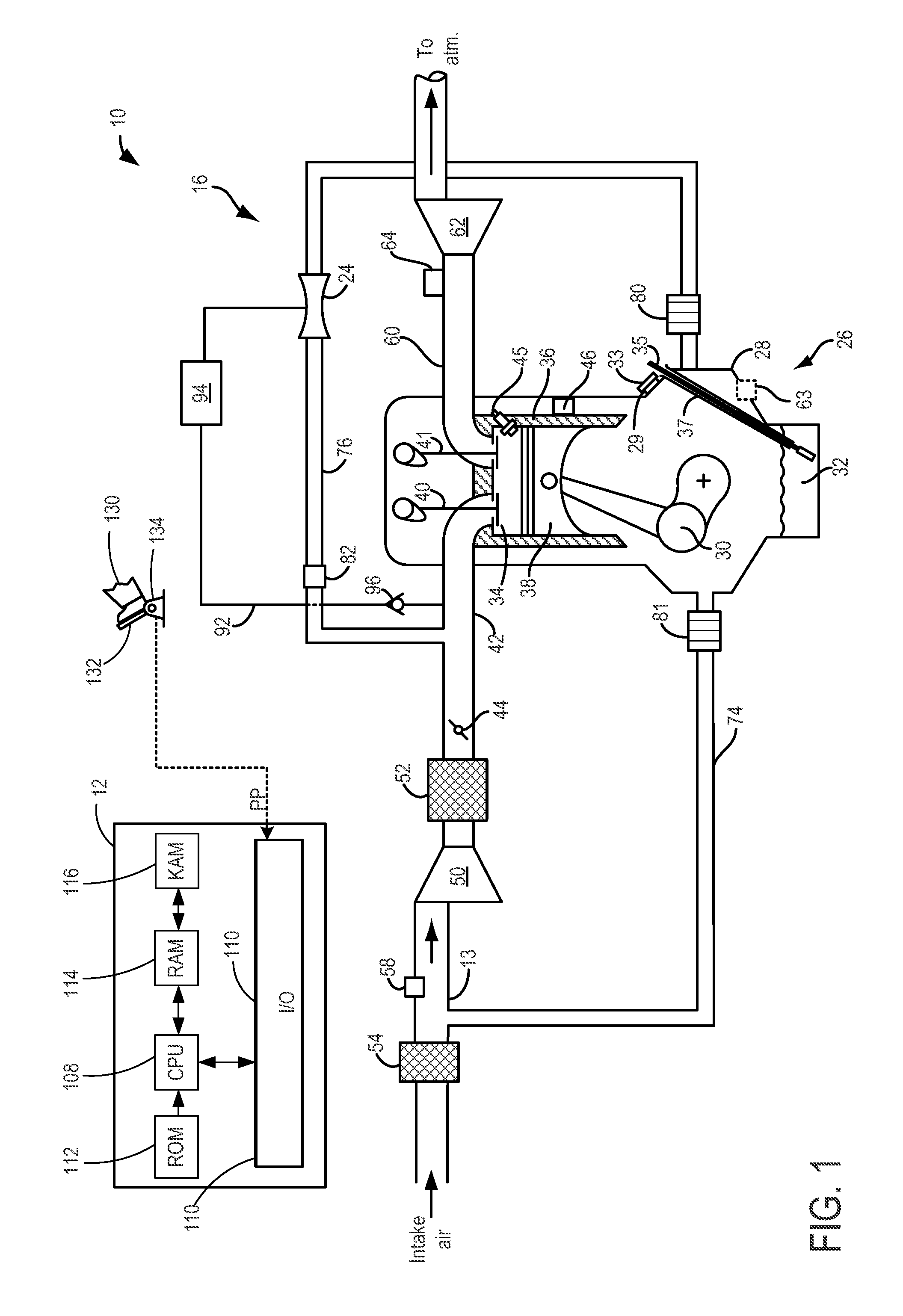

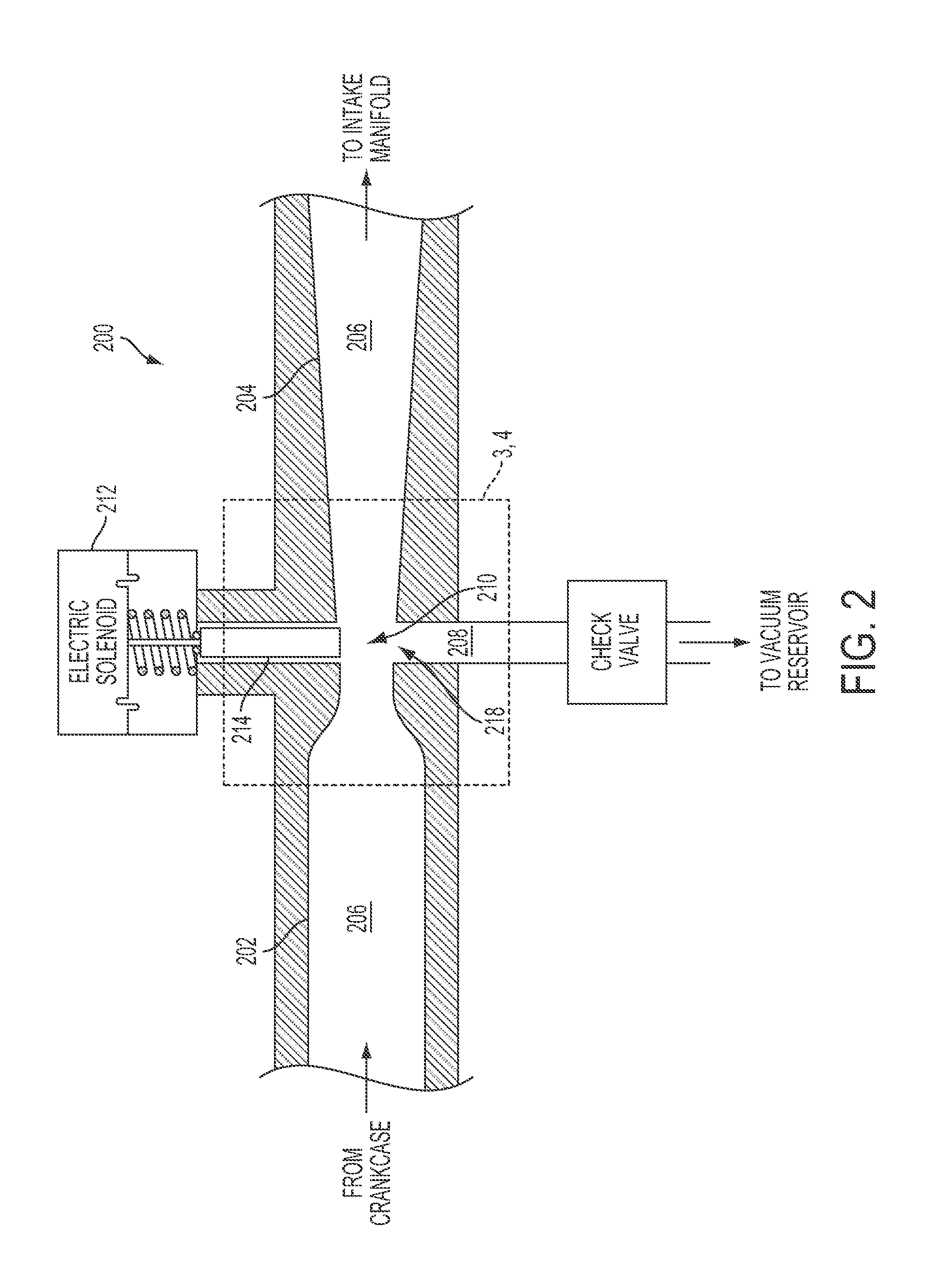

[0020]The following description relates to systems and methods for using an aspirator (e.g., the aspirator of FIG. 2 or FIG. 5) for both crankcase ventilation and vacuum generation. The aspirator may function as a PCV valve, and PCV flow through the aspirator may generate vacuum depending on a position of a pintle of the aspirator, the pintle including an orifice through which PCV flow is metered when the aspirator is fully closed. An engine controller may be structured to perform control routines, such as the methods of FIGS. 6-8, to select an aspirator operating mode and to control an actuator to move the pintle into a position corresponding to the selected operating mode and a current vacuum state, current vacuum requests, and engine constraints on aspirator flow rate. In this way, an aspirator in a PCV line coupling the crankcase and intake of an engine may serve as a PCV valve, thus reducing the need for any other means of PCV flow regulation to be included in the PCV system, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com