Hydrogenation for processing and utilizing coal tar

A technology for coal tar and hydrogenation reaction, which is applied in the direction of refining tar by chemical method, etc., can solve the problems of not considering the utilization of coal residue oil and the low utilization rate of coal tar resources, and achieves easy condensation of green coke, easy processing, and hydrogenation. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0047] The coal tar raw materials are processed under different operating conditions, and the middle distillate oil is not fed into the second-stage hydrogenation reactor of the hydrogenation unit for further processing. The properties of the raw materials used are shown in Table 1. The objective function of the processing is that the hydro-modified pitch meets the indicators of carbon fiber raw materials: softening point: 118-124°C; coking value: 50-52°C; toluene insoluble matter: 5-10%; quinoline insoluble matter: 0.02- 0.04%; Ash: 0.01-0.06%; Sulfur: 0.5-2.5%.

[0048] Density (20℃), g / cm 3

[0049] * IBP refers to the initial boiling point of oil

[0050] * EBP refers to the final boiling point of oil

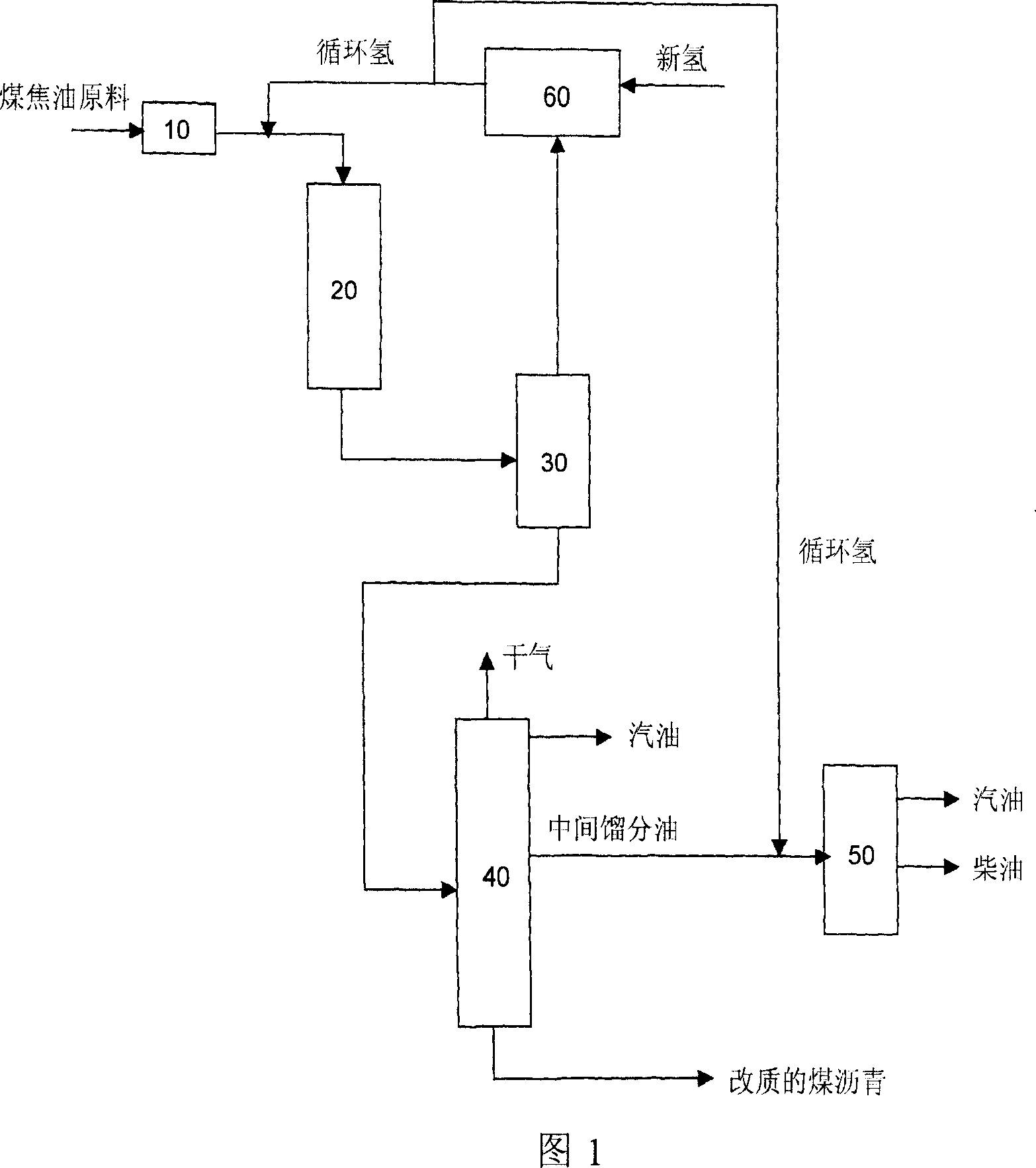

[0051] The specific operation process is shown in Figure 1. The filling scheme of the reactor catalyst is to install the hydrogenation protective agent on the upper part, the molybdenum oxide content is 8.0%, the nickel oxide content is 1.7%, the pore volume is 0.58m...

Embodiment 5-8

[0058] The coal tar raw materials are processed under different operating conditions, and the middle distillate oil enters the second-stage hydrogenation reactor of the hydrogenation unit for processing. The operating conditions of the one-stage hydrogenation reactor of the coal tar feedstock hydrogenation unit and the properties of the raw materials used are the same as those in Examples 1-4. The operating conditions of the two-stage hydrogenation reactor of the hydrogenation unit and the properties of the produced oil are shown in Table 6.

[0059] The specific operation process is shown in Figure 1. The two-stage hydrogenation reactor catalyst of the hydrogenation unit is filled with a special hydrogenation catalyst for coal tar. The catalyst has a tungsten oxide content of 19%, a molybdenum oxide content of 9%, a nickel oxide content of 5%, and a pore volume of 0.32ml / g, the specific surface is 180m 2 / g.

[0060] Example

5

6

7

8

Reactio...

Embodiment 9

[0068] The difference from Examples 1-4 is that the filling scheme of the hydrogenation protective agent and catalyst in the reactor is:

[0069] The upper part is equipped with hydrogenation protective agent, the content of molybdenum oxide is 16.0%, the content of nickel oxide is 0.5%, the rest is support alumina, the pore volume is 0.95ml / g, and the specific surface area is 250m 2 / g, the filling amount is 15% of the total volume of the catalyst.

[0070] The rest are filled with special hydrogenation catalyst for coal tar, the support is silica-containing alumina, and the nature of the support: pore volume 1.0~1.3cm 3 , The specific surface area is greater than 350m 2 ·G -1 , SiO 2 The content is 9.0~12.0m%; the tungsten oxide content of the catalyst is 27m%, the molybdenum oxide content is 10m%, the nickel oxide content is 8m%, the pore volume is 0.50ml / g, and the specific surface area is 182m. 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com