Paracresol separation method

A separation method, the technology of p-cresol, applied in the field of separation, can solve the problems of complex process, complicated separation process, and large solvent consumption, and achieve the effect of simple process, simple operation, and avoiding a large amount of solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

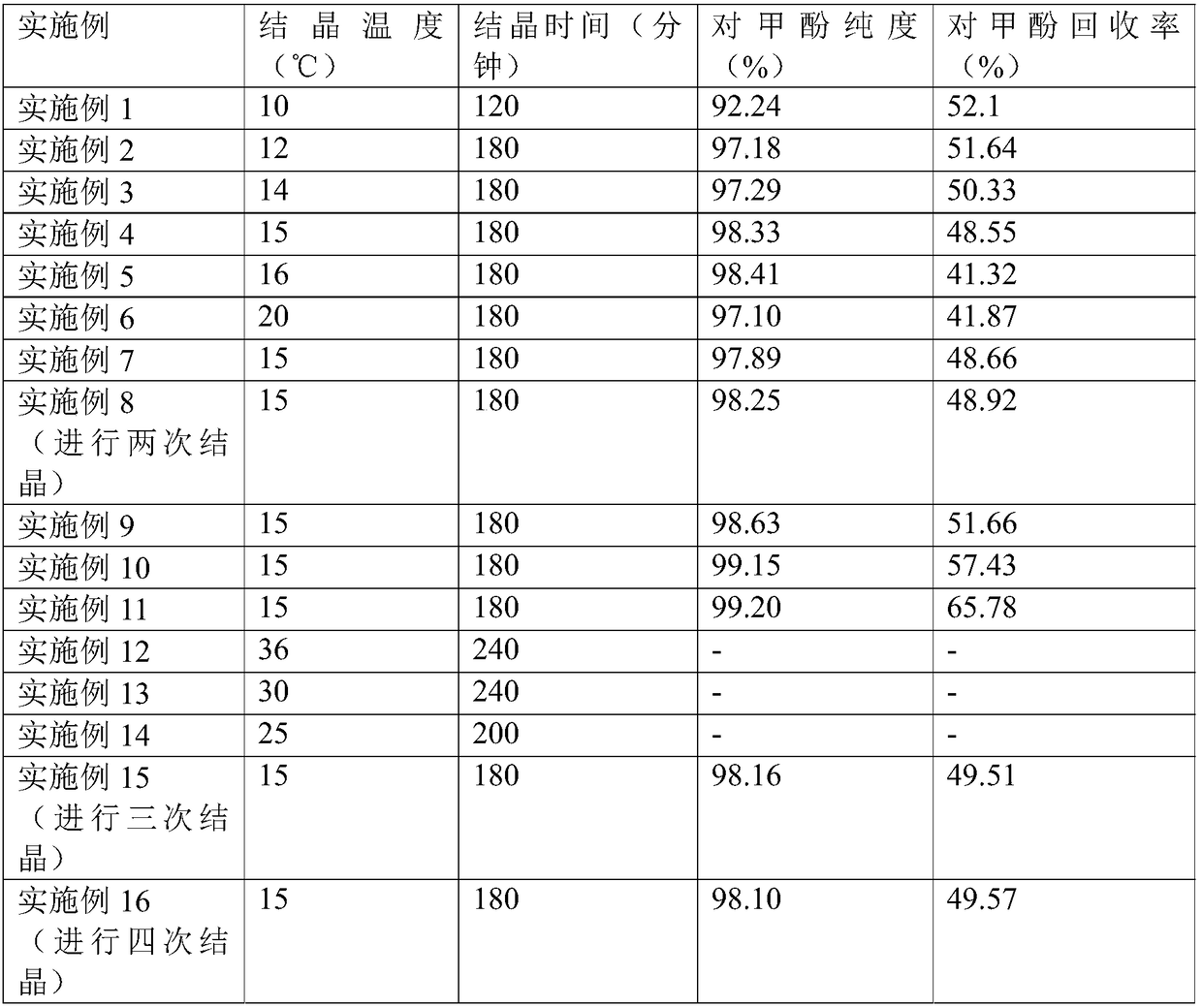

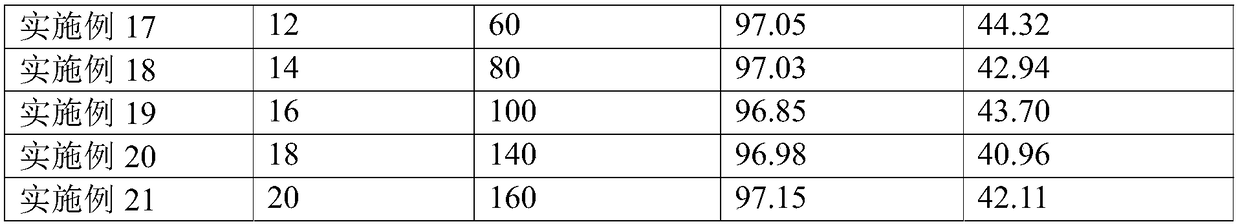

Examples

Embodiment 1

[0036] A mixture with 60% p-cresol from coal liquefied oil was used as a mixed mother liquor. Add the mixed mother liquor to the reaction kettle with cold trap and stirring; turn on the stirring and low-temperature cold trap, and lower the cold trap to 10°C, add p-cresol crystals as seed crystals, the seed crystal size is 200 mesh, and make the mixed mother liquor in Crystallize in the reaction kettle for 120 minutes to generate p-cresol crystalline products; in a cold trap at a temperature of 20°C, suction-filter the mixed mother liquor containing the crystalline products, and quickly transfer the obtained crystalline products. The analysis results of p-cresol purity and yield are shown in Table 1.

Embodiment 2

[0038] A mixture with 60% p-cresol from coal tar was used as a mixed mother liquor. Add the mixed mother liquor into the reaction kettle with cold trap and stirring; turn on the stirring and low-temperature cold trap, and lower the cold trap to 12°C, and stir for 180 minutes; add p-cresol crystals as seed crystals, the seed crystal size is 200 mesh, Stir and crystallize, and react for a period of time to generate p-cresol crystalline products; in a cold trap at a temperature of 20°C, suction-filter the mixed mother liquor containing the crystalline products, and quickly transfer the obtained crystalline products. The analysis results of p-cresol purity and yield are shown in Table 1.

Embodiment 3

[0040] A mixture with 60% p-cresol of crude phenol oil from mixed phenols was used as a mixed mother liquor. Add the mixed mother liquor to the reaction kettle with cold trap and stirring; turn on the stirring and low-temperature cold trap, and lower the cold trap to 14°C, add p-cresol crystals as seed crystals, the seed crystal size is 200 mesh, and make the mixed mother liquor in Crystallize in the reaction kettle for 180 minutes to generate p-cresol crystalline products; in a cold trap at a temperature of 20°C, suction-filter the mixed mother liquor containing the crystalline products, and quickly transfer the obtained crystalline products. The analysis results of p-cresol purity and yield are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com