Low-temperature selective catalytic reduction (SCR) for flue gas denitrification and preparation method for low-temperature SCR catalyst

A SCR catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as immature technology, and achieve the effects of low price, strong adsorption capacity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

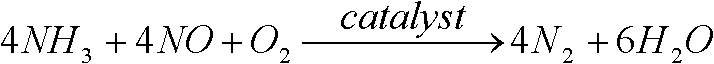

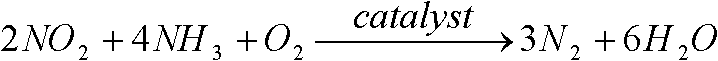

Method used

Image

Examples

Embodiment 1

[0030] A preparation method for the low-temperature SCR catalyst for flue gas denitrification, comprising the following steps:

[0031] 1) Pulverizing the pyrolysis slag, the particle size is 60-200 mesh;

[0032]2) Weigh 10g of waste tire pyrolysis slag, immerse in 13g of 90wt% phosphoric acid aqueous solution, keep stirring at room temperature for 1 hour to activate phosphoric acid, then dry at 110°C for 48h, and then use high-temperature water in a sealed furnace under nitrogen atmosphere. The steam is activated by water vapor, the activation temperature is 800°C, the activation time is 3 hours, and finally the sample is washed with deionized water to make the pH of the liquid 6-7;

[0033] 3) Add 5 g of the above-mentioned modified waste tire pyrolysis slag into 2.4 g of 90 wt% ferromanganese nitrate aqueous solution (the molar ratio of Fe and Mn in the solution is 1:1), soak for 3 hours, and then dry it in a water bath The main catalyst is loaded, then dried at 120° C., ...

Embodiment 2

[0036] A preparation method for the low-temperature SCR catalyst for flue gas denitrification, comprising the following steps:

[0037] 1) Pulverizing the pyrolysis slag, the particle size is 60-200 mesh;

[0038] 2) Weigh 10g of waste tire pyrolysis slag, immerse it in 20g of 60wt% phosphoric acid aqueous solution, keep stirring at room temperature for 1 hour, then dry at 110°C for 48h, and then use high-temperature water in a sealed furnace under nitrogen atmosphere. The steam is activated by water vapor, the activation temperature is 800°C, and the activation time is 1 hour. Finally, the sample is washed with deionized water to stabilize the pH value of the liquid at 6-7;

[0039] 3) Add 5 g of the above-mentioned modified waste tire pyrolysis slag into 18.8 g of 10 wt % manganese nitrate aqueous solution and soak for 3 h (the molar ratio of Fe and Mn in the solution is 0:1), and then dry in a water bath to complete the main process. The catalyst is loaded, then dried at 1...

Embodiment 3

[0042] A preparation method for the low-temperature SCR catalyst for flue gas denitrification, comprising the following steps:

[0043] 1) Pulverizing the pyrolysis slag, the particle size is 60-200 mesh;

[0044] 2) Take 10g of waste tire pyrolysis slag, immerse it in 15g of 80wt% phosphoric acid aqueous solution, keep stirring at room temperature for 1 hour, then dry at 110°C for 48h, then carry out high temperature activation under nitrogen atmosphere, the activation temperature is 800°C, the activation time is 2 hours, and finally the sample is washed with deionized water to stabilize the pH value of the liquid between 6 and 7. Put the sample into the furnace again, pass water vapor (flow rate is 3g / hour), the activation temperature is 900°C, and the activation time is 2 hours;

[0045] 3) Add 5 g of the above-mentioned modified waste tire pyrolysis slag into 2.6 g of manganese nitrate / iron nitrate aqueous solution (the molar ratio of Fe and Mn in the solution is 0.5:1) w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Volume concentration | aaaaa | aaaaa |

| Volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com