Device and method for drying clothes at low temperature through mechanical vapor recompression (MVR)

A technology of mechanical steam and drying equipment, which is applied in washing equipment, household clothes dryers, textiles and papermaking, etc. It can solve the problems of high water consumption, high energy consumption, and large cooling water consumption, and achieve simple process flow and high operating temperature. Low, lower operating temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

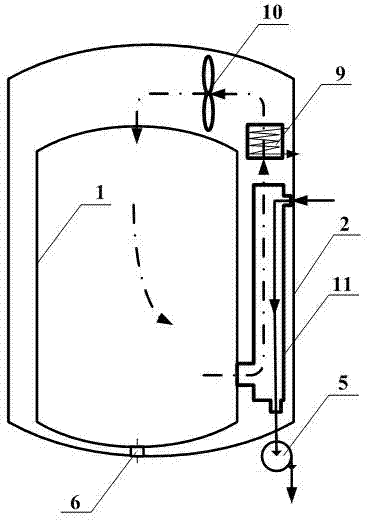

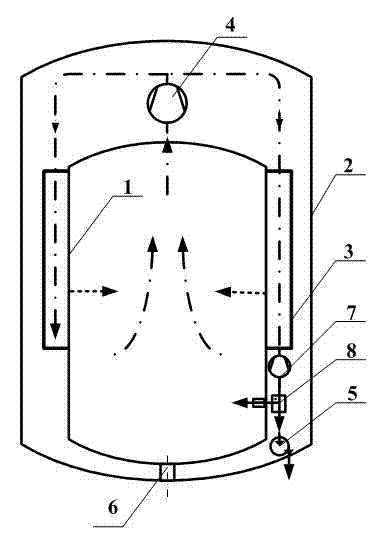

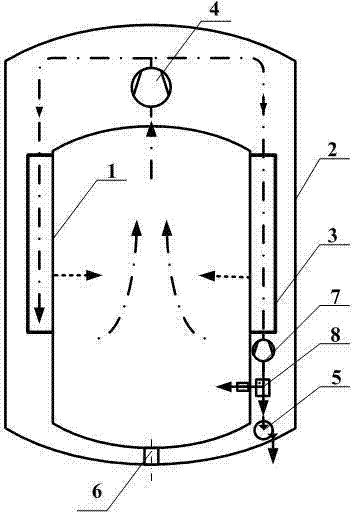

[0019] Referring to the accompanying drawings, the present invention provides a mechanical vapor recompression low-temperature clothes drying device and method. It is characterized in that it includes a drum 1, a sealing jacket 3 installed on the heat conduction wall of the drum 1, a casing 2 installed outside the sealing jacket 3, and also includes a compressor 4, a drainage pump 5, an expander 7 and a gas-liquid separator 8. The outlet of drum 1 is connected with the inlet of compressor 4, the outlet of compressor 4 is connected with sealing jacket 3, the gas phase outlet of sealing jacket 3 is connected with the inlet of drum 1, the outlet of sealing jacket 3 is connected with the inlet of expander 7, and the outlet of expander 7 It is connected with the inlet of the gas-liquid separator 8, and the gas-liquid separator has a liquid phase outlet and a gas phase outlet. The outlet of the pump 5 is connected to the external environment;

[0020] Refer to the attached figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com