Grease rich in unsaturated fattyacid and preparation method thereof

A technology of unsaturated fatty acids and mixed fatty acids, which is applied in the field of oil rich in unsaturated fatty acids and its preparation, and achieves the effects of high yield, low operating temperature and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

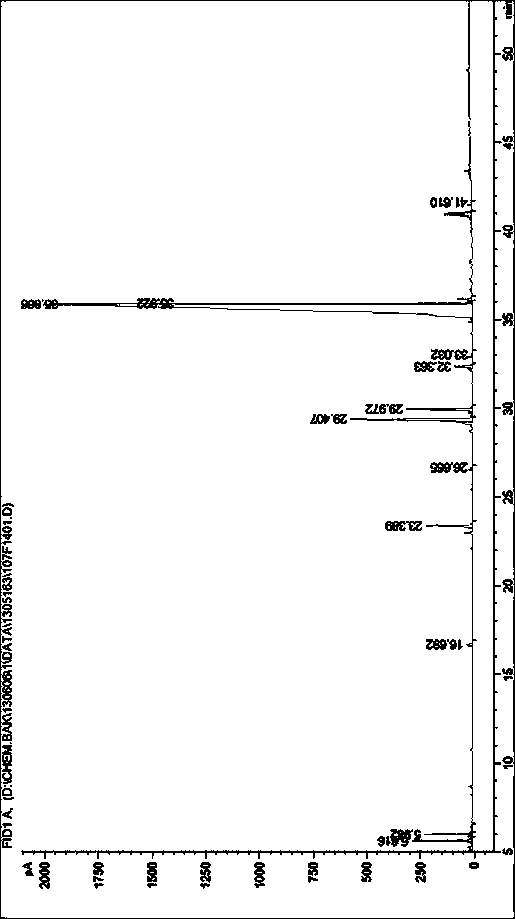

Image

Examples

Embodiment 1

[0015] Example 1, the oil rich in unsaturated fatty acids is obtained according to the following preparation method: the first step, the horse fat is ground, and the ground horse fat is heated to obtain liquid oil, that is, horse oil; the second step , after mixing horse oil and saponification agent at a mass ratio of 1:2 to 1:5, saponification reaction is carried out at a temperature of 50°C to 90°C for 0.5h to 3h to obtain a saponification liquid; the third step is to saponify Liquid and distilled water are mixed according to the mass ratio of 1:1 to 4:1 to obtain a mixed solution, and the mixed solution is extracted by adding n-hexane to the mixed solution according to the mass ratio of the mixed solution to n-hexane of 2:1 to 6:1. Obtain the n-hexane layer and the water layer, discard the n-hexane layer, adjust the pH of the water layer to 1 to 4 with mineral acid, and then add the water layer to the water layer according to the mass ratio of the water layer and n-hexane ...

Embodiment 2

[0016] Example 2, the oil rich in unsaturated fatty acids is obtained according to the following preparation method: the first step is to grind the horse fat, and heat the ground horse fat to obtain liquid oil, namely horse oil; the second step , after mixing horse oil and saponification agent at a mass ratio of 1:2 or 1:5, saponification reaction is carried out at a temperature of 50°C or 90°C for 0.5h or 3h to obtain a saponification liquid; the third step is to saponify Liquid and distilled water are mixed according to the mass ratio of 1:1 or 4:1 to obtain a mixed solution, and the mixed solution is extracted by adding n-hexane to the mixed solution according to the mass ratio of the mixed solution to n-hexane of 2:1 or 6:1. Obtain the n-hexane layer and the water layer, discard the n-hexane layer, adjust the pH of the water layer to 1 or 4 with mineral acid, and then add the water layer to the water layer at a ratio of 2:1 or 6:1 according to the mass ratio of the water ...

Embodiment 3

[0017] Embodiment 3, as a preference of the above-mentioned embodiment, in the first step, the horse fat is cleaned with distilled water, the fascia impurities are removed, dried and then minced; or / and, in the first step, the minced Horse fat is heated at a temperature of 50° C. to 80° C. to obtain liquid oil, namely horse oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com