Base Heat Spreader With Fins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

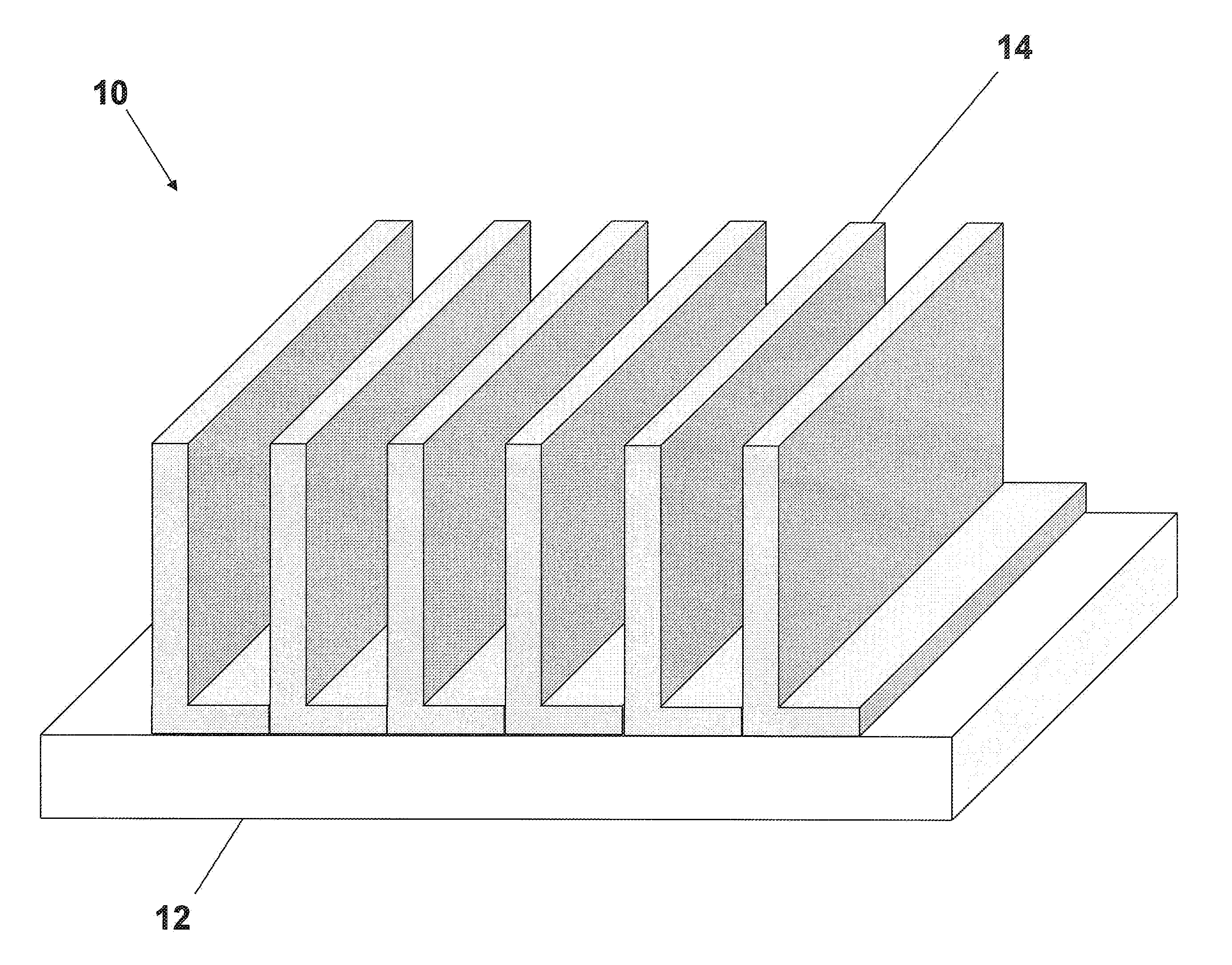

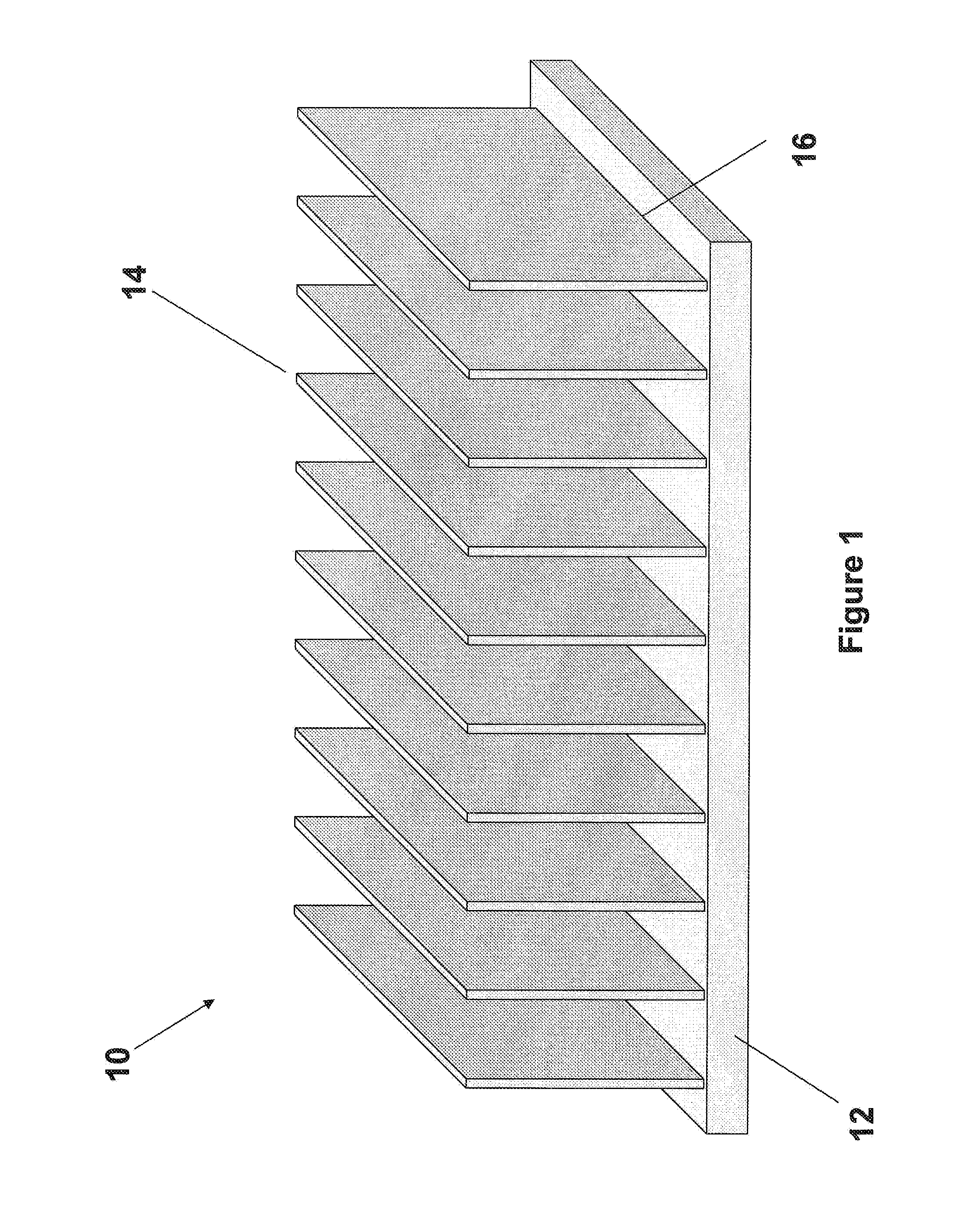

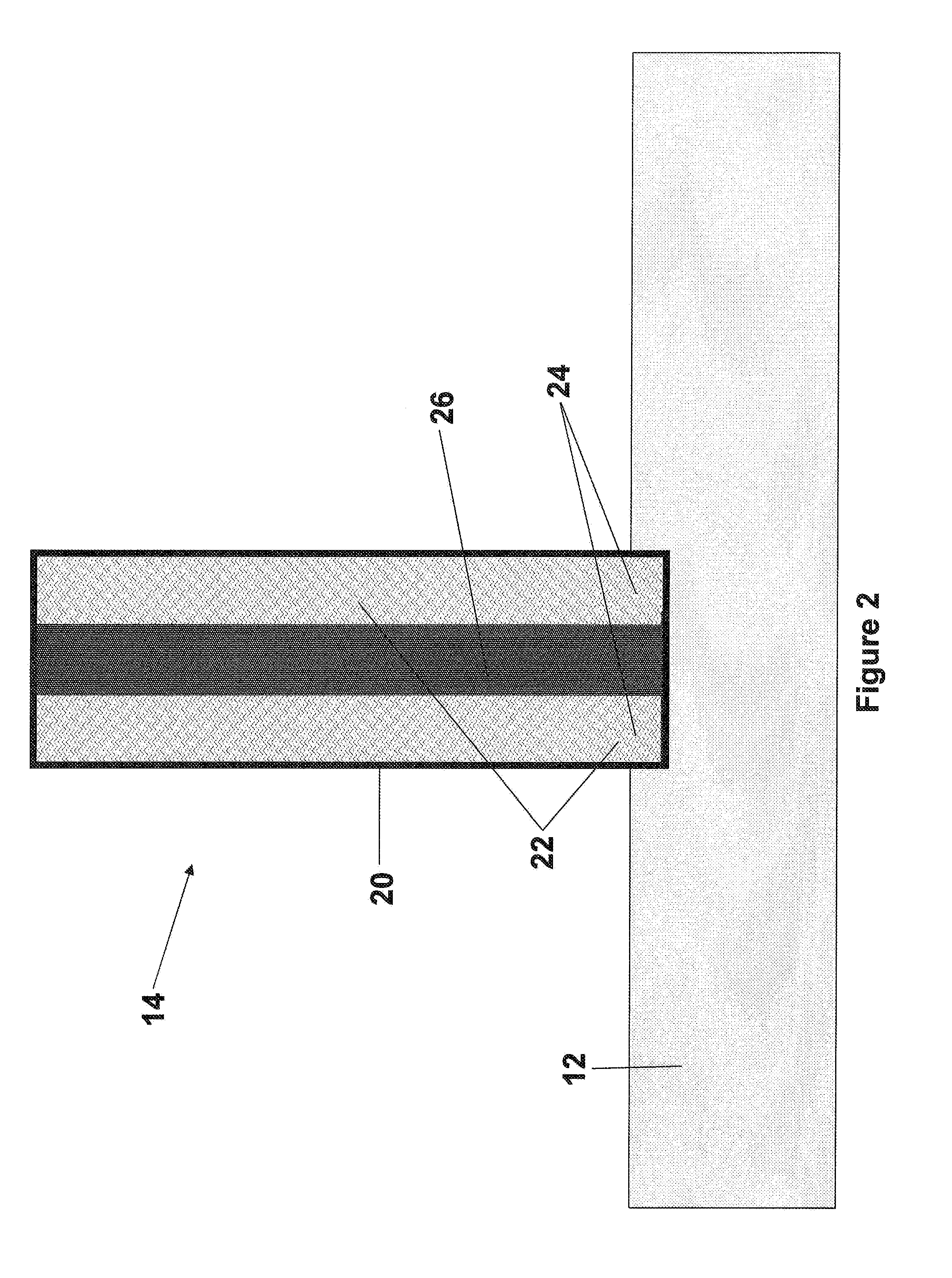

[0042]The thermal management device in accordance with the present invention can improve both the performance and functional lifespan of an electronic device through the reduction of the operating temperature of the device. Specifically, the invention provides for greater reduction in the temperature of the electronic device than prior art devices through improved convection, namely the transfer of thermal energy from the inventive thermal management device to the surrounding air.

[0043]In configurations including the use of a fan component, forced convection occurs as the fan imposes external motion onto the air. Forced convection provides for typically better cooling as air is continuously in motion over the heat sink and provides a larger gradient of temperatures resulting in a larger thermal flux. With the improved thermal dissipation qualities of the present invention, less airflow is necessary as the thermal management device is more efficient for a given airflow. As such, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com