Room-temperature liquid-phase Claus process taking ionic liquid as media

An ionic liquid, normal temperature technology, applied in gas treatment, separation methods, dispersed particle separation, etc., to achieve the effects of no VOCs emissions, low energy consumption, and low operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

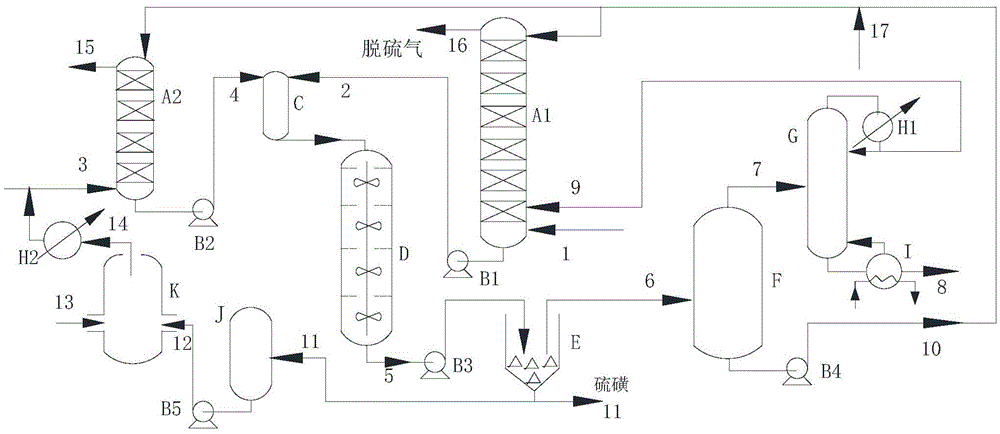

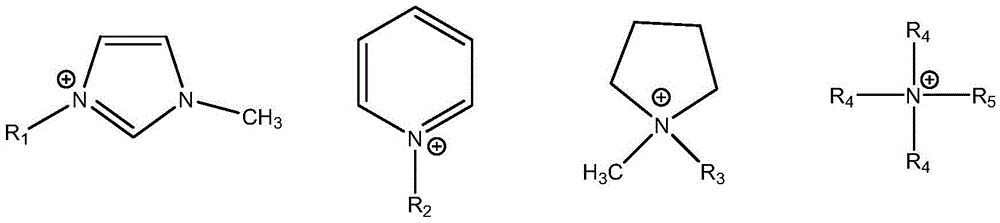

[0033] Embodiment 1: its technology sees attached figure 1 , the absolute pressure is 1MPa, the temperature is 30℃, H 2 The natural gas whose S content (mol fraction) is 1% is input into the large absorption tower A1 at 1 place. The absorbing liquid used is the ionic liquid 1-hexyl-3-methylimidazolium chloride ([hmim][Cl]). The operating temperature of the large absorption tower A1 is normal temperature, the operating pressure is 1MPa, and the operating liquid-gas ratio is 20Kg / Nm 3 . The operating temperature of the small absorption tower A2 is normal temperature, the operating pressure is normal pressure, and the operating liquid-gas ratio is 5Kg / Nm 3 . Contains SO 2 The pressure of the gas flow is normal pressure and the temperature is 30°C, and it enters the small absorption tower A2 from position 3. The packing used in absorption towers A1 and A2 is mellapak250Y. The operating pressure of the reaction tower D is 1MPa, the operating temperature at the top of the tow...

Embodiment 2

[0035] Embodiment 2: its technique is similar to embodiment 1, see attached figure 1 , the absolute pressure is 0.1MPa, the temperature is 30℃, H 2 The coke oven gas with S content (mole fraction) of 3% is input into the large absorption tower A1 from one place. The ionic liquid used is trifluoroacetic acid-triethylbutylammonium salt ([N 2224 ][CF 3 COO - ]). The operating temperature of the large absorption tower A1 is normal temperature, and the operating liquid-gas ratio is 40Kg / Nm 3 . The operating temperature of the small absorption tower A2 is normal temperature, and the operating pressure is normal pressure. Contains SO 2 The gas flow pressure is normal pressure, the temperature is 30°C, and the operating liquid-gas ratio is 5Kg / Nm 3 , and enter the small absorption tower A2 from position 3. The packing used in absorption towers A1 and A2 is mellapak250Y. The operating pressure of the reaction tower D is 1MPa, the operating temperature at the top of the tower ...

Embodiment 3

[0036] Embodiment 3: its technique is similar to embodiment 1, see attached figure 1 , the absolute pressure is 1MPa, the temperature is 30℃, H 2 Hydrodesulfurized gas with S content (mole fraction) of 2% is input into large absorption tower A1 from 1 place. The ionic liquid used was N-butylpyridinium chloride ([BuPy][Cl]). The operating temperature of the large absorption tower A1 is normal temperature, and the operating liquid-gas ratio is 10Kg / Nm 3 . The operating temperature of the small absorption tower A2 is normal temperature, the operating pressure is normal pressure, and the operating liquid-gas ratio is 5Kg / Nm 3 . Contains SO 2 The pressure of the gas flow is normal pressure and the temperature is 30°C, and it is input into the absorption tower A2 from position 3. The packing used in absorption towers A1 and A2 is mellapak250Y. The operating pressure of the reaction tower D is 1MPa, the operating temperature at the top of the tower is normal temperature, H 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com