Internal steam engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

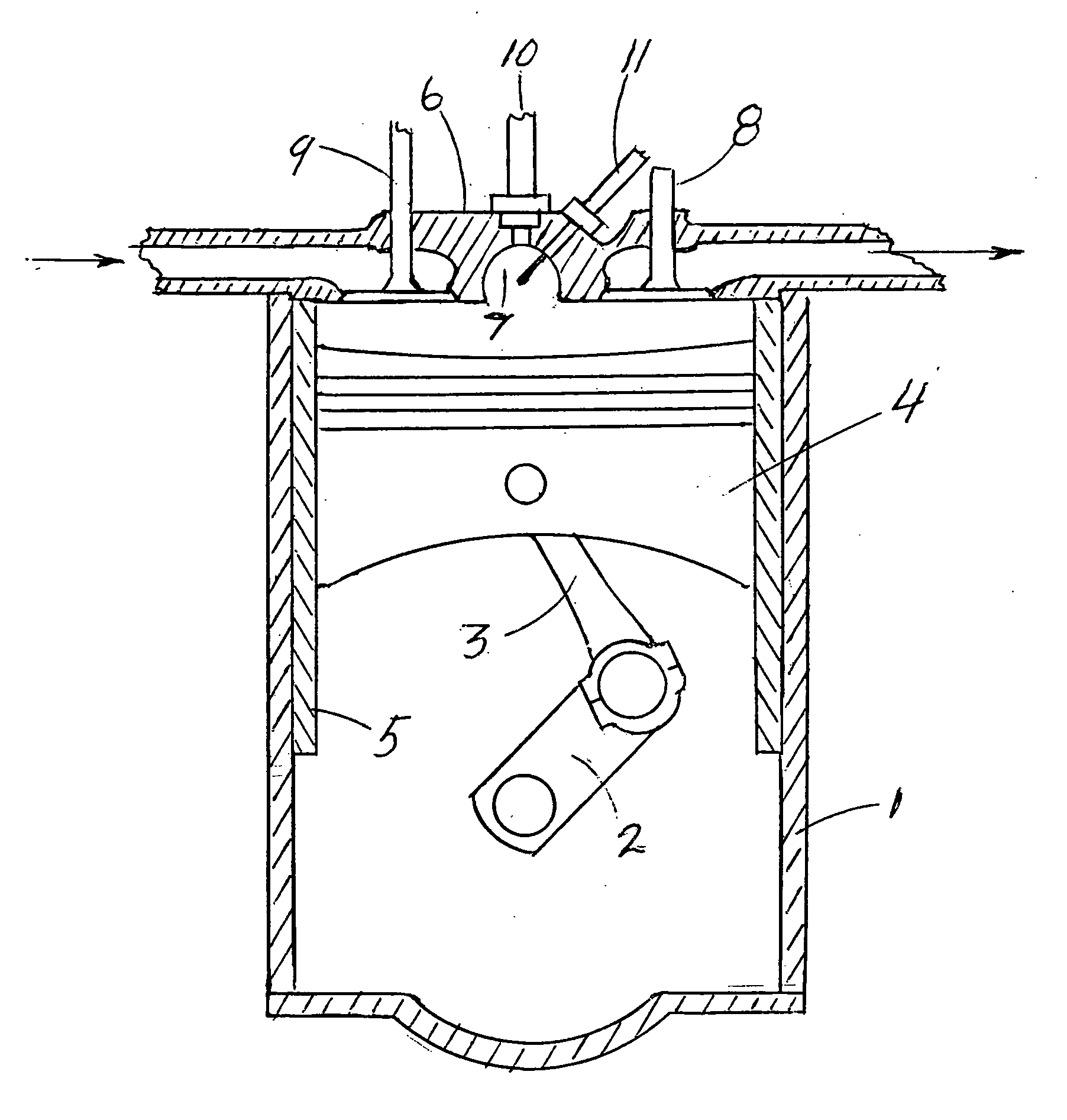

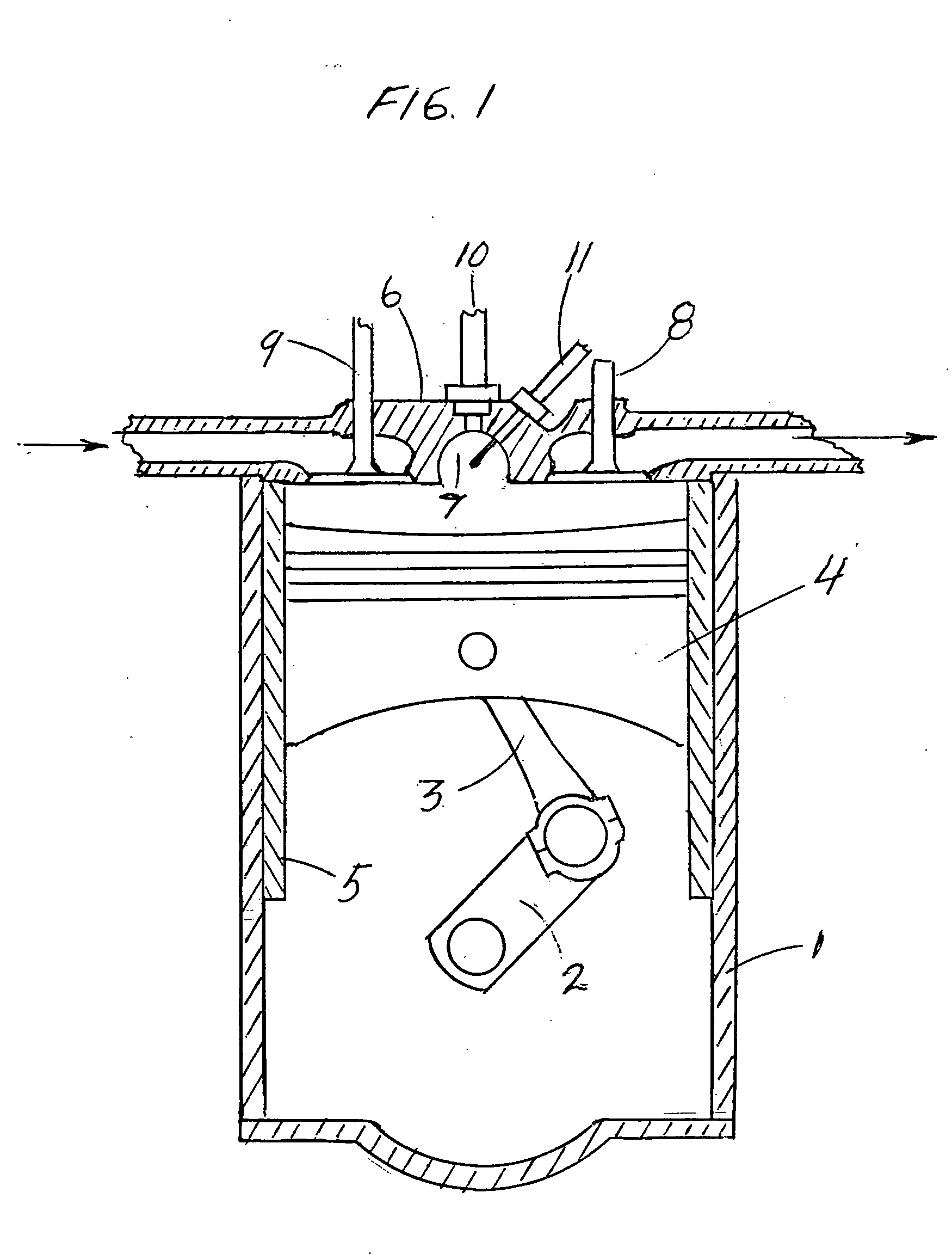

[0011] With reference to FIG. 1, a four-stroke version of an internal steam engine includes a crankcase 1, a rotary crankshaft 2, connected to rod 3, affixed to piston 4, cylinder 5, cylinder head 6, pre-chamber 7, exhaust valve 8, intake valve 9, injector 10 and heating element 11.

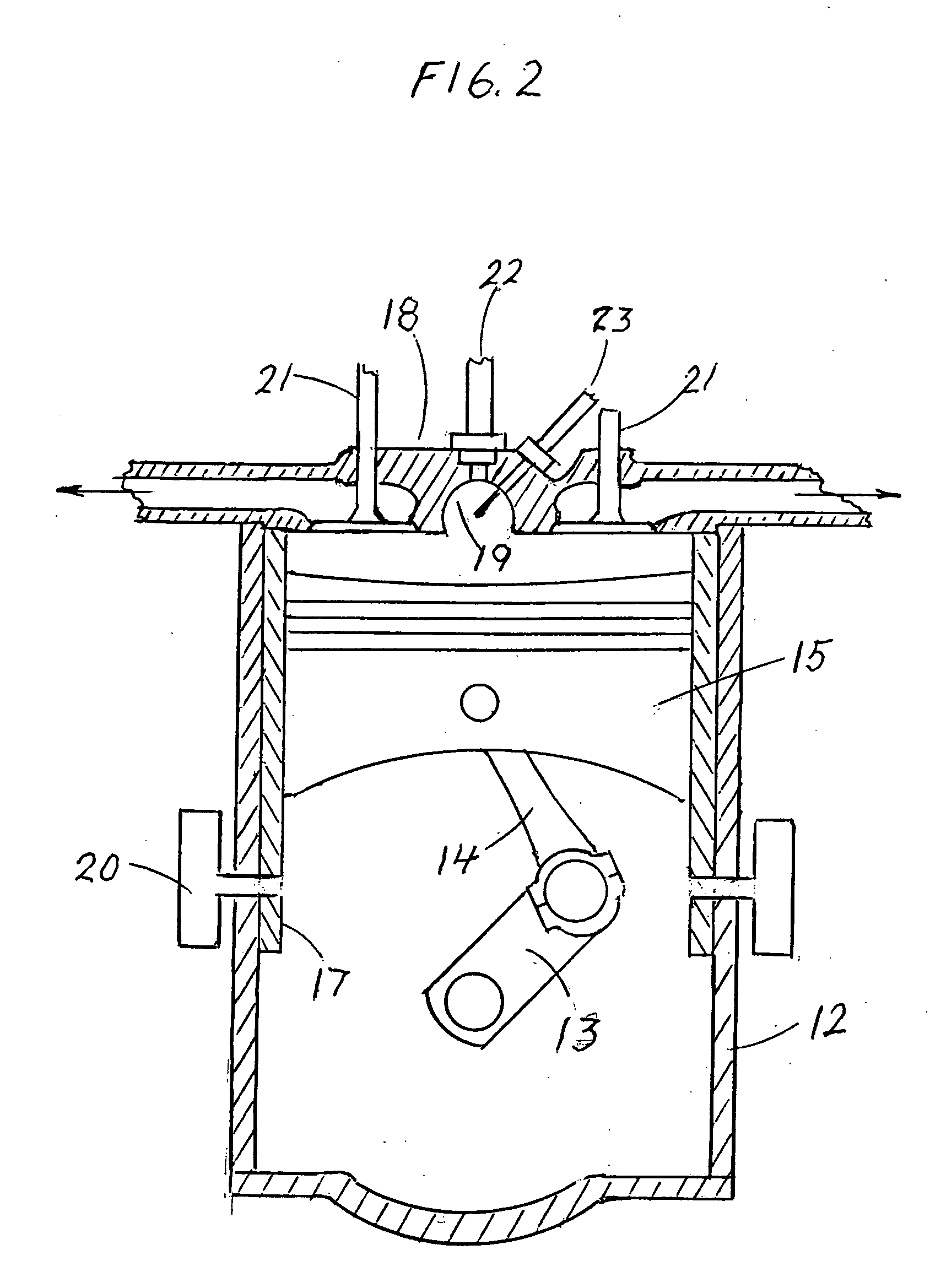

[0012] With reference to FIG. 2, a two-stroke version of an internal steam engine includes a crankcase 12, a rotary crankshaft 13, rod 14, piston 15, cylinder 17, cylinder head 18, pre-chamber 19, air intake ports 20, exhaust valve 21, injector 22, and heating element 23.

[0013] In a four-stroke embodiment of the invention, the cycle of the internal steam engine comprises six main stages which are air intake, compression, steam generation, expansion, exhaust and condensation as outlined schematically in the following figures.

[0014]FIG. 3—Air Intake: The piston is moving from top dead center to bottom dead center to draw in fresh air through the opening of the intake valve.

[0015]FIG. 4—Compression: Whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com