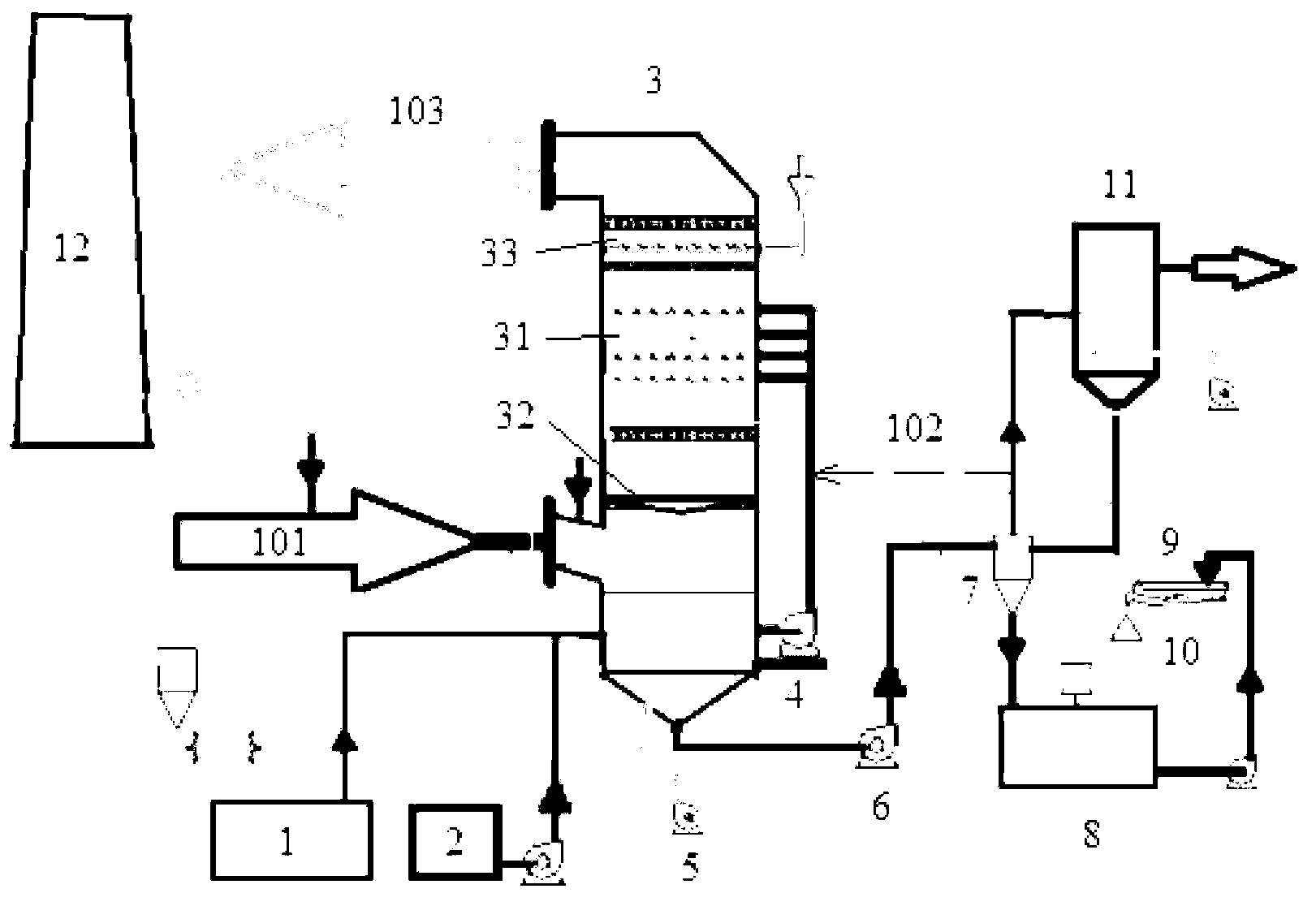

Method for dedusting and desulfurizing catalytic-cracking oil refining regenerated flue gas

A technology for regenerating flue gas and catalytic cracking, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of large energy loss, high flue gas resistance, and high water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 200 g of light-burned magnesium oxide powder, add 5 L of warm water at 40° C. for aging, and convert it into a magnesium hydroxide slurry with a mass concentration of 5.5%. Mix the remaining 140 g of 30% sodium hydroxide solution, dilute it with water to 10 L, and stir well to prepare 2 sodium-magnesium composite desulfurization solutions containing 2.9% magnesium hydroxide concentration and 0.4% sodium hydroxide concentration, wherein Na / Mg is 0.2.

[0028] Put the desulfurization slurry into the desulfurization tower for spray absorption desulfurization, the simulated flue gas flow rate is 20m 3 / h. Liquid to gas ratio 1L / m 3 , The desulfurization tower has a diameter of 150mm and a height of 1000mm. The desulfurization slurry is sprayed down from the top of the tower and contacts the simulated flue gas in the reverse direction. The flue gas passes through a desulfurization and dust removal strengthening unit. reaction, the desulfurization slurry absorbs su...

Embodiment 2

[0031] Weigh 12Kg of light-burned magnesium oxide powder, dissolve 0.6Kg of sodium alkali in 300L of water, stir well, and configure a desulfurization slurry with a magnesium hydroxide concentration of about 5%, wherein Na / Mg is 0.05. Put the desulfurization slurry into the desulfurization tower for spray absorption desulfurization. The simulated flue gas flow rate is 2000m 3 / h, the dust content in the simulated flue gas is 180mg / m 3 , sulfur dioxide is 800mg / m 3 . Under this condition, the liquid-gas ratio is 2L / m 3 , The desulfurization tower has a diameter of 480mm and a height of 3000mm. The desulfurization slurry is sprayed down from the top of the tower and contacts with the flue gas in the reverse direction. The flue gas passes through the desulfurization and dust removal strengthening unit. The desulfurization slurry absorbs sulfur oxides and particulate matter in the flue gas. The desulfurization efficiency is 97%, and the dust removal efficiency is 96%.

[00...

Embodiment 3

[0034] The actual small-scale FCC regeneration furnace is used for the test, and the flue gas volume is 10000m3 3 / h. The dust content in the flue gas is 120mg / m 3 , sulfur dioxide is 900mg / m 3 , nitrogen oxide content 300mg / m 3 , at the flue gas inlet, through the sampling generator, after calculation, add ozone gas with a concentration of 300ppm.

[0035] Magnesium hydroxide and sodium hydroxide are dissolved in water respectively to form magnesium hydroxide and sodium hydroxide slurries, and the desulfurization slurry obtained after mixing by a slurry pump has a magnesium hydroxide concentration of 5%, and Na / Mg is 0.1. Put the desulfurization slurry into the desulfurization tower for spray absorption desulfurization. Liquid to gas ratio 3L / m 3 , The desulfurization tower has a diameter of 1000mm and a height of 10000mm. The desulfurization slurry is sprayed down from the top of the tower and contacts with the flue gas in the reverse direction. The flue gas passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com