Oil washing and energy saving technology and device for condensing and recycling destructive distillation oil and gas of oil shale

A condensation recovery and energy-saving device technology, which is applied in the petroleum industry, special dry distillation, chemical industry, etc., can solve the problems of large amount of waste water, large amount of circulating water, and large energy consumption, so as to reduce the amount of waste water and improve the recovery rate and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

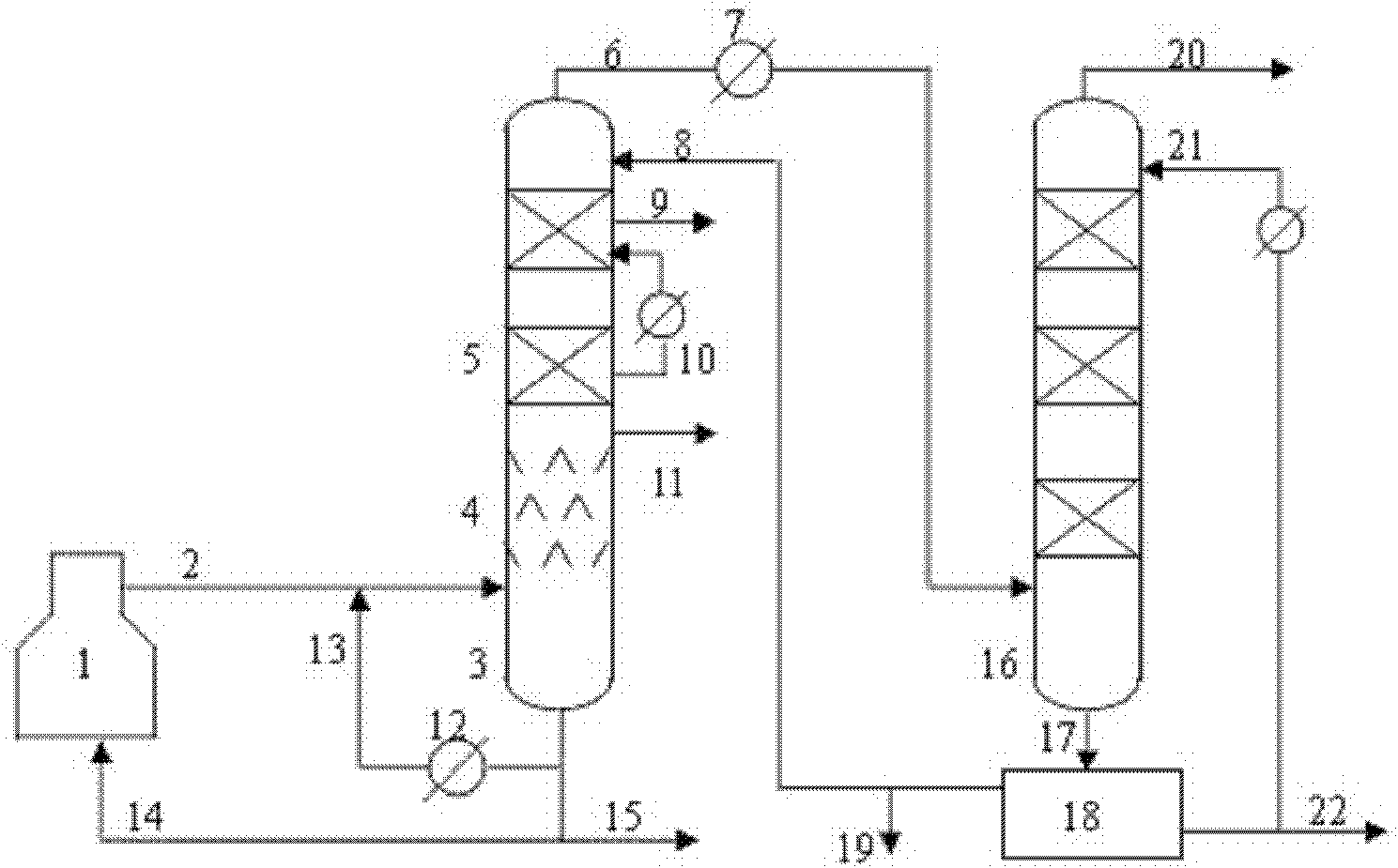

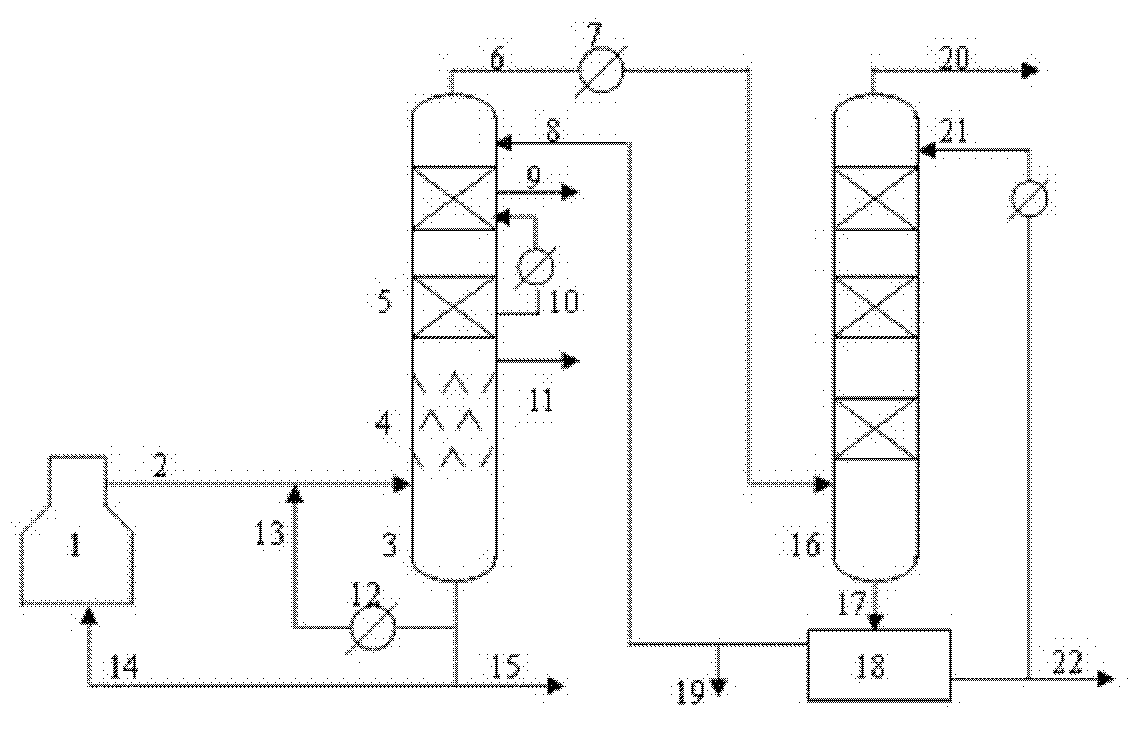

[0020] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0021] Such as figure 1 Shown: the bottom of the oil washing tower (3) is provided with a condenser (12), the top of the tower is provided with a condenser (7), and the tower is provided with structured packing (5) and anti-clogging internals (4); raw gas ( 2) The inlet is in the middle and lower part of the oil washing tower (3); the dusty heavy oil outlet is set at the bottom of the tower; the shale oil (11) and naphtha (9) outlets, the circulating light oil inlet (8) and the middle circulation ( 10); the top of the water washing tower (16) is provided with a non-condensable steam (20) outlet; the middle and lower part is provided with gas and light oil (6) inlets, which are connected to the oil-water separator (18); the oil-water separator (18) is connected with the return oil washing A circulating light oil (8) pipeline is connected between the towers (3), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com