Waste Ni-Co-Mn lithium manganate positive electrode material recycling method

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the field of recycling waste nickel-cobalt lithium manganese oxide positive electrode materials, can solve the problems of long process flow, high recovery cost and low profit of the recovery process, and achieve short process flow and high-quality products. The effect of high added value and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

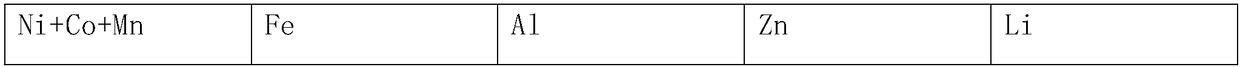

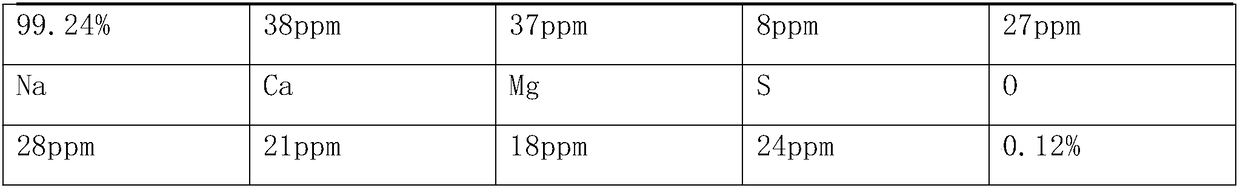

Embodiment 1

[0030] A kind of recovery method of waste and old nickel-cobalt lithium manganese oxide cathode material, it is the following steps:

[0031] (1) Pretreatment, disassemble the waste nickel-cobalt lithium manganese oxide battery, put the positive plate into the liquid nitrogen freezer for crushing, then sieve, pass through a 150-mesh sieve, and return the sieve to continue freezing and crushing. The sieve is ready for use;

[0032](2) Put the undersize obtained in step (1) into the reduction furnace, feed hydrogen to reduce, the residence time of the undersize in the reduction furnace is 10 hours, and the charging thickness of the undersize in the sagger 4.5cm, the flow rate of hydrogen in the reduction furnace is 4m / s, the hydrogen content in the atmosphere in the reduction furnace is greater than 99.5%, the reduction temperature is 425°C, and then it is cooled to the temperature <40°C in the cooling section of the reduction furnace before it is released from the furnace get ...

Embodiment 2

[0045] A kind of recovery method of waste and old nickel-cobalt lithium manganese oxide cathode material, it is the following steps:

[0046] (1) Pretreatment, disassemble the waste nickel-cobalt lithium manganese oxide battery, put the positive plate into the liquid nitrogen freezer for crushing, then sieve, pass through a 120-mesh sieve, and return the sieve to continue freezing and crushing. The sieve is ready for use;

[0047] (2) put the undersize obtained in step (1) into the reduction furnace, feed hydrogen to reduce, the residence time of the undersize in the reduction furnace is 11 hours, and the charging thickness of the undersize in the sagger 4.2cm, the flow rate of hydrogen in the reduction furnace is 4.5m / s, the hydrogen content in the atmosphere in the reduction furnace is greater than 99.5%, the reduction temperature is 440°C, and then cooled to the temperature <40°C in the cooling section of the reduction furnace out of the furnace to obtain the raw materials...

Embodiment 3

[0061] A kind of recovery method of waste and old nickel-cobalt lithium manganese oxide cathode material, it is the following steps:

[0062] (1) Pretreatment, disassemble the waste nickel-cobalt lithium manganese oxide battery, put the positive plate into the liquid nitrogen freezer for crushing, then sieve, pass through a 170-mesh sieve, return the sieve to continue freezing and crushing, The sieve is ready for use;

[0063] (2) put the undersize that step (1) obtains in the reduction furnace, pass into hydrogen to reduce, the residence time of the undersize in the reduction furnace is 9.5 hours, the charging thickness of the undersize in the sagger 4.5cm, the flow rate of hydrogen in the reduction furnace is 4.2m / s, the hydrogen content in the atmosphere in the reduction furnace is greater than 99.5%, the reduction temperature is 440°C, and then cooled to the temperature <40°C in the cooling section of the reduction furnace out of the furnace to obtain the raw materials; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com