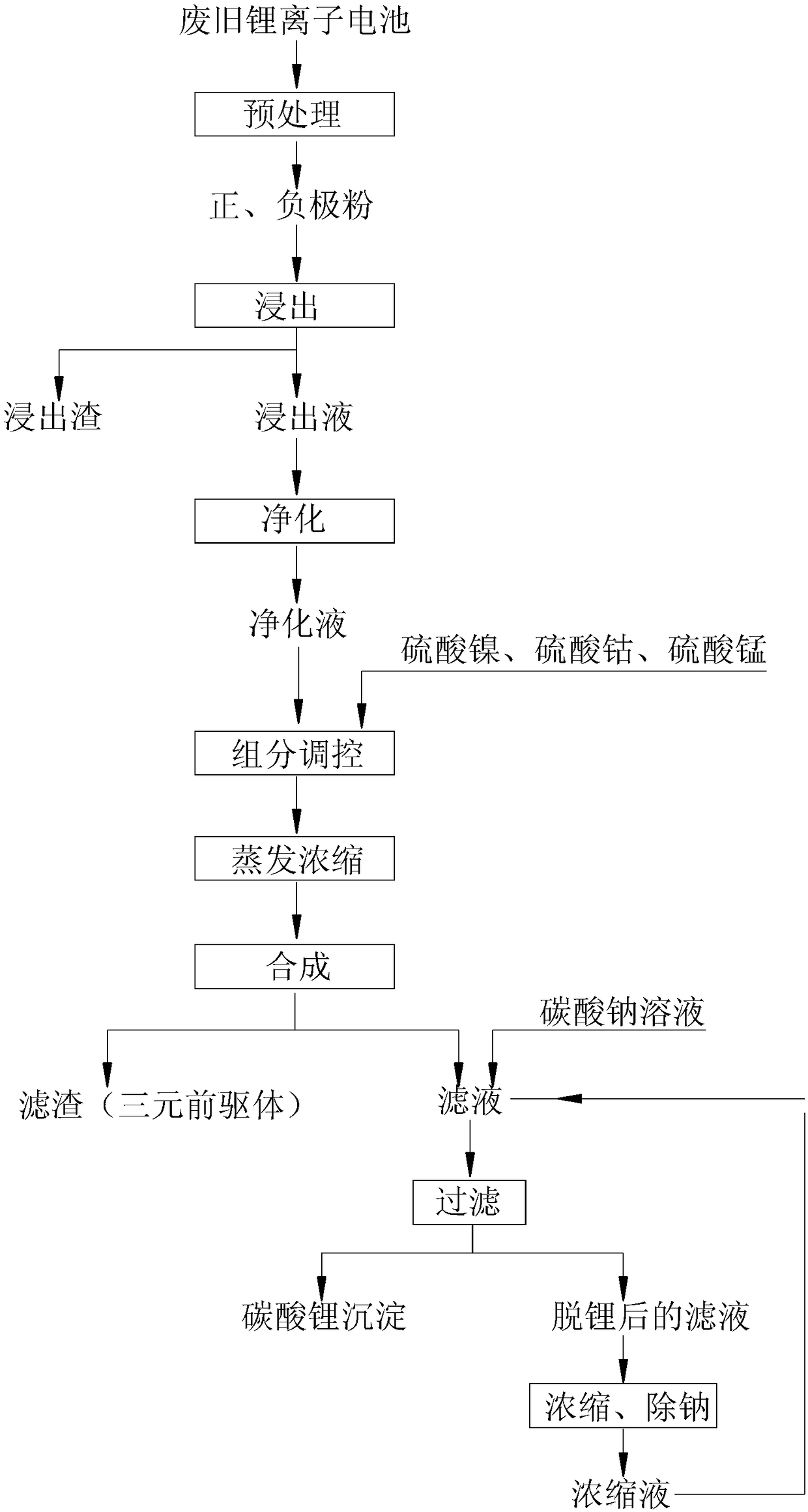

A method for recovering valuable metals from waste lithium ion batteries

A lithium-ion battery and valuable metal technology, which is applied in the field of lithium-ion battery waste recycling, can solve the problems of difficulty in industrialization, increase power consumption, increase leaching residue, etc., and achieve high added value of products, cost saving, and low consumption of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]Pretreatment: Weigh 100kg ternary lithium-ion battery waste, disassemble to obtain battery blocks and shells, use a shredder to cut the battery blocks to a size of 10mm*10mm, place them in a pyrolysis furnace for pyrolysis and distillation after cutting, and The distilled battery material is crushed to a particle size of about 80-100 mesh, and the crushed battery material enters a sieving machine and a sorting machine to obtain 55.61 kg of positive and negative electrode powder, 6.90 kg of copper foil, 9.5 kg of aluminum foil and 3.0 kg of plastic film. The recovery rate of nickel, cobalt, manganese and lithium in the pretreatment is about 96%, and the proportion of copper and aluminum entering the positive and negative electrode powder is about 1.5% and 5%. The content of each element before and after pretreatment is shown in Table 1.

[0044] Each element content (mass %) before and after the raw material pretreatment of table 1

[0045] element

[0046] Lea...

Embodiment 2

[0069] Pretreatment: Weigh 100kg monobasic lithium cobaltate battery waste, disassemble to obtain battery blocks and shells, use a shredder to cut the battery blocks to a size of 10mm*15mm, place them in a pyrolysis furnace for pyrolysis and distillation after cutting, and The distilled battery material is pulverized to a particle size of 100-200 mesh, and the pulverized battery material enters a sieving machine and a sorting machine to obtain 54.63 kg of positive and negative electrode powder, 6.85 kg of copper foil, 9.42 kg of aluminum foil and 2.95 kg of plastic film. The recovery rate of cobalt and lithium is about 98%, and the proportion of copper and aluminum entering the positive and negative electrode powders is about 2.2% and 5.80%. The content of each element before and after pretreatment is shown in Table 10.

[0070] Each element content (mass %) before and after table 10 raw material pretreatment

[0071] element

[0072] Leaching: Take 1kg of the posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com