Graphene preparation method

A graphene and graphite intercalation technology, applied in the field of graphene, can solve the problems of difficulty in obtaining lamellae, a small number of lamellae, and high manufacturing costs, so as to reduce potential safety hazards and environmental pollution, mild peeling reactions, and reduce the generation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

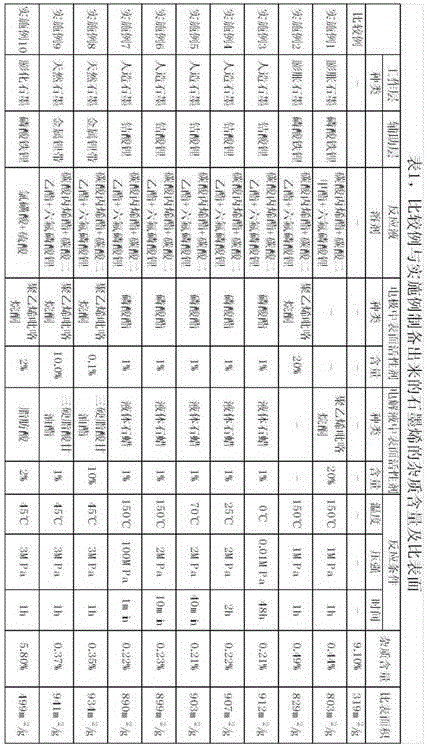

Image

Examples

Embodiment 1

[0039] Preparation of working electrode: prepare slurry according to the quality relationship of expanded graphite: super conductive carbon: styrene-butadiene rubber = 96:3:1, and then apply it on the copper foil current collector to prepare working electrode;

[0040] Preparation of the auxiliary electrode: Prepare the slurry according to the quality relationship of lithium iron phosphate: conductive carbon black: polyvinylidene fluoride = 95:4:1, and then apply it on the aluminum foil current collector to prepare the auxiliary electrode;

[0041] Assembly: The working electrode and the auxiliary electrode are cut into the same shape, and then assembled directly, so that the working layer and the auxiliary layer are completely corresponding, and the pre-reaction body is obtained.

[0042] The preparation of graphene reactant: with propylene carbonate: dimethyl carbonate = 1:1 mixed solution as solvent, 1mol / L lithium hexafluorophosphate as solute solution as initial electrolyt...

Embodiment 2

[0044] Embodiment 2, different from Embodiment 1, this embodiment includes:

[0045] Preparation of working electrode: prepare slurry according to the quality relationship of expanded graphite: super conductive carbon: styrene-butadiene rubber: polyvinyl pyrrolidone=75:4:1:20, and then apply it on the copper foil current collector to prepare working electrode;

[0046] Preparation of the graphene reactant: using a mixture of propylene carbonate: diethyl carbonate = 1:1 as a solvent, and a solution of 1.1 mol / L lithium hexafluorophosphate as a solute as an electrolyte (reaction solution). The electrolyte is injected into the pre-reaction body, and after it is fully infiltrated, the pre-reaction body is placed in an environment of 150 ° C, and a surface pressure of 1 MPa is applied at the same time, so that ion channels and electronic channels are formed between the expanded graphite and lithium iron phosphate at the same time. The exfoliation of the expanded graphite can be car...

Embodiment 3

[0048] Embodiment 3, the preparation of working electrode: according to artificial graphite: super conductive carbon: styrene-butadiene rubber: phosphoric acid ester=95:3:1:1 mass relation prepares slurry, is coated on the copper foil current collector afterwards and prepares to obtain working electrode electrode;

[0049] Preparation of the auxiliary electrode: Prepare the slurry according to the mass relationship of lithium cobaltate: conductive carbon black: polyvinylidene fluoride = 95:4:1, and then apply it on the aluminum foil current collector to prepare the auxiliary electrode;

[0050] Assembly: The working electrode and the auxiliary electrode are cut into the same shape, and then assembled directly, so that the working layer and the auxiliary layer are completely corresponding, and the pre-reaction body is obtained.

[0051] The preparation of graphene reactant: with propylene carbonate: diethyl carbonate = 1:1 mixed solution as solvent, 1mol / L lithium hexafluoropho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com