Electroplating sludge recycling technology

A technology of electroplating sludge and process, which is applied in the direction of sludge treatment, process efficiency improvement, water/sludge/sewage treatment, etc. It can solve the problems of high investment cost, unsuitable waste liquid disposal, etc., and achieve high purity and filtration Good detergency and detergency, uniform crystal particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

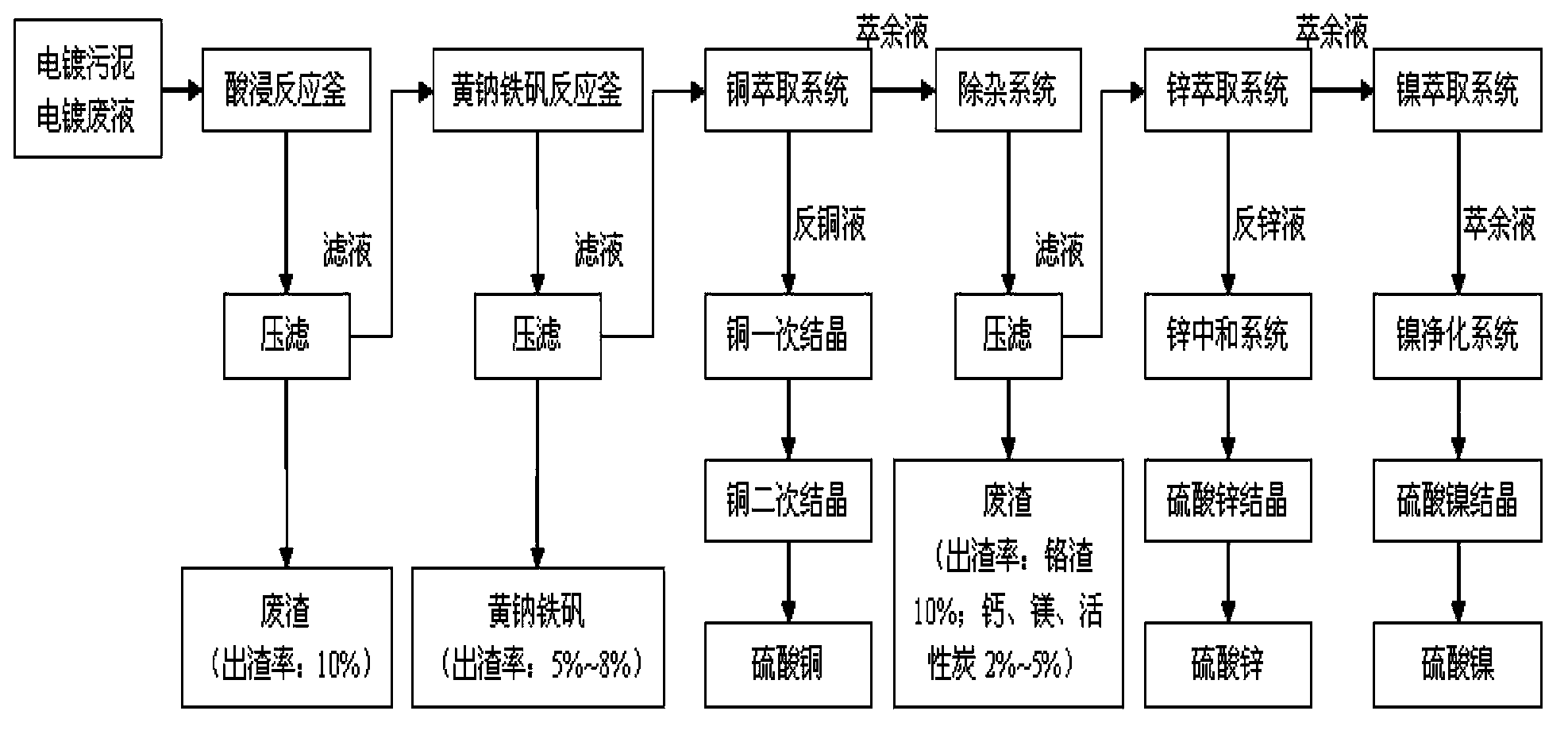

[0030] In order to deepen the understanding of the present invention, the following drawings will further describe the present invention in detail. This embodiment is only used to explain the present invention, and does not constitute a limitation to the protection scope of the present invention.

[0031] see figure 1 As shown, the present invention provides an electroplating sludge recycling process: acid leaching, the electroplating waste liquid is first treated with a low-acid leaching process, and the leached residue is then subjected to high-acid leaching; iron removal, the electroplating waste liquid through acid leaching is treated with yellow sodium The ferrite method is used to remove iron, so that the iron content of the solution is less than 1 g / L. After iron removal, it is washed and filtered. The nickel hydroxide produced is washed by pressure filtration until the filtrate is colorless. The nickel hydroxide is dissolved with sulfuric acid, and the pH of the solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com