Culture/harvesting method of microalgae and system

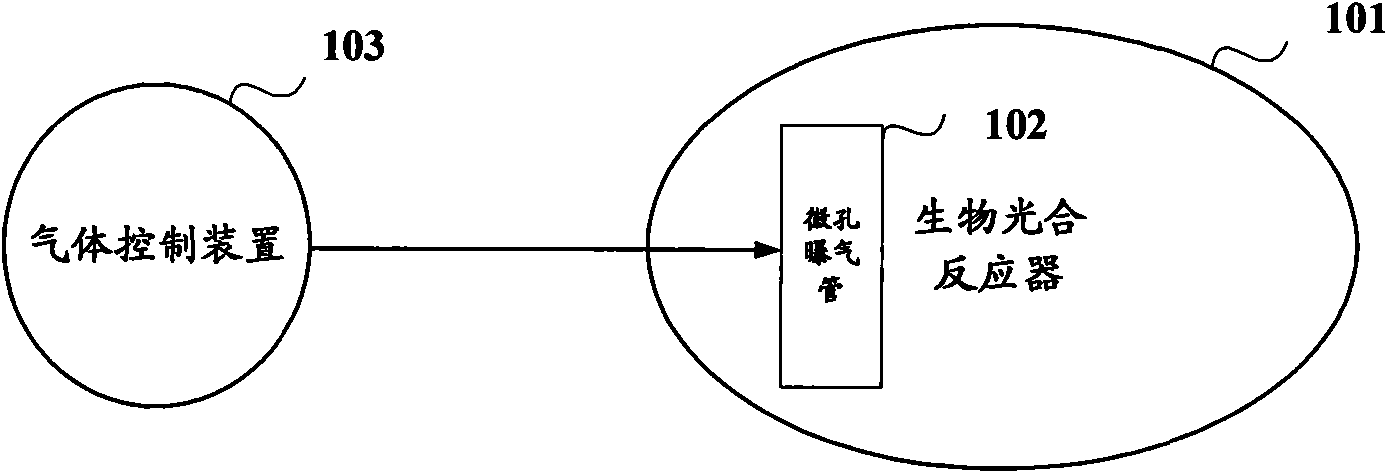

A technology of microalgae cultivation and microalgae, applied in the field of microorganisms, can solve problems such as low utilization rate, and achieve the effects of realizing rapid separation of solid and liquid, increasing yield, and increasing gas-liquid contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make it easier for those skilled in the art to understand and realize the present invention, the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The drawings are only used to help better understand the solutions of the embodiments, and may not be limited to the forms shown in the drawings in various implementations.

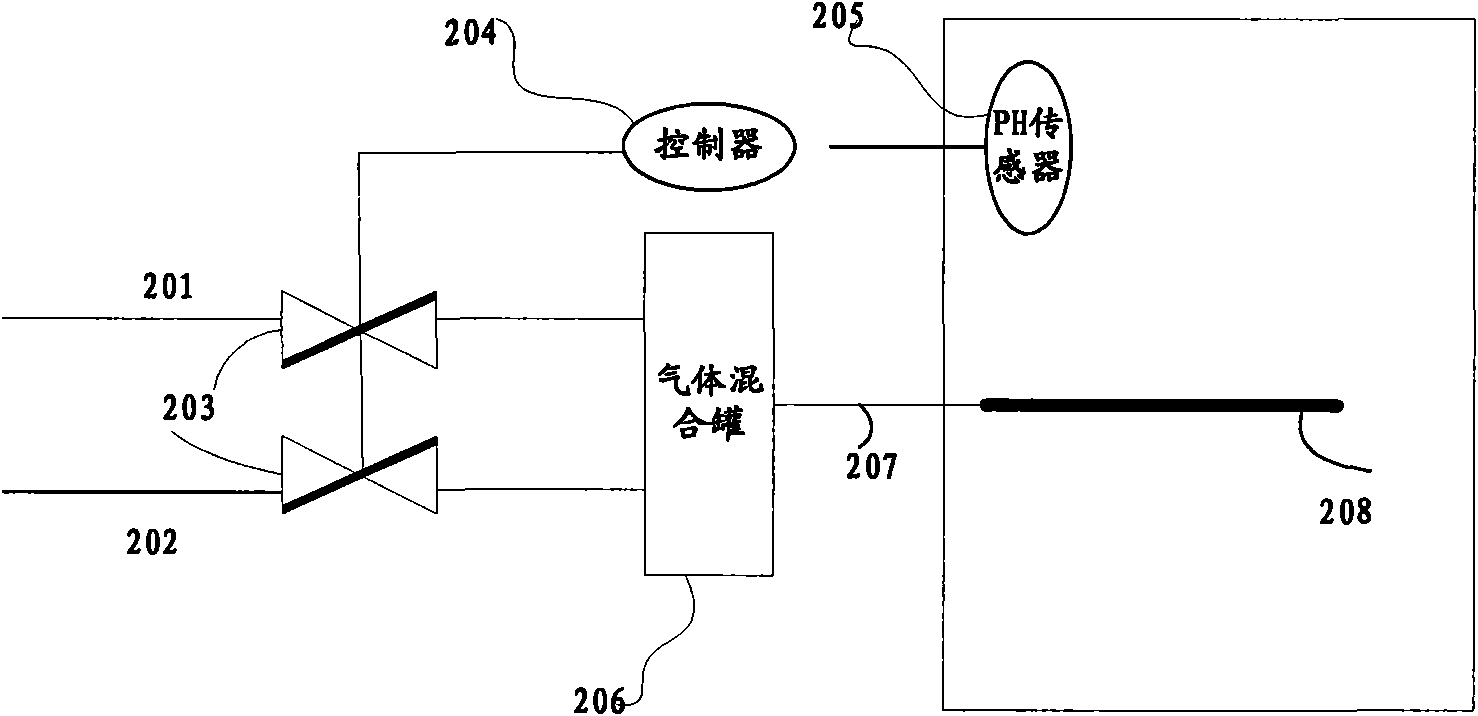

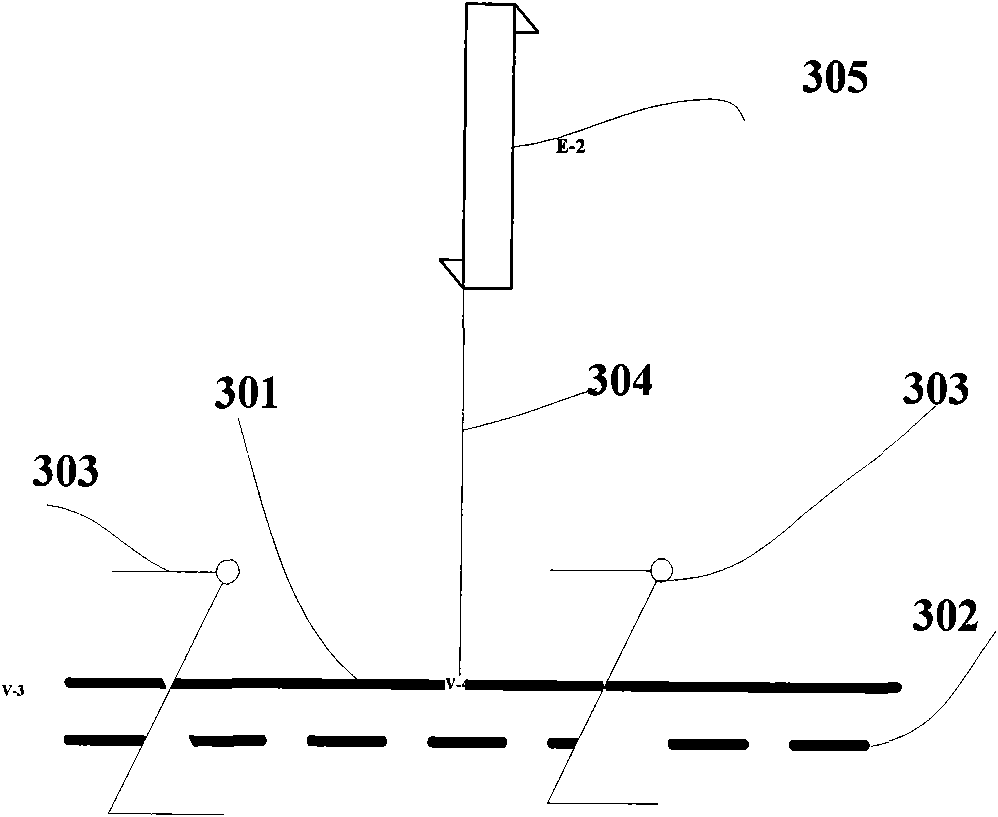

[0039] Considering that when microalgae are cultivated, microalgae need to absorb a large amount of CO during photosynthesis 2 and other inorganic substances to synthesize organic substances such as glucose and release oxygen and other substances. thus increasing the CO 2 The residence time and CO in the algae liquid 2 The contact area with the algae liquid is very important. The CO used in the embodiment of the present invention 2 The gas is rich in CO obtained after desulfurization, dust removal, and waste heat recovery. 2 Gas factory waste gas enters the algae liquid in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com