Ceramic pedestal pan with rearmounted flushing pipeline and manufacturing process thereof

A production process and toilet technology, applied in the field of ceramics, can solve the problems of affecting the sewage discharge effect, not being able to fully exert the effective effect of the sewage discharge, weakening the momentum, etc., and achieve the effects of high product qualification rate, reasonable structure, and reduced flushing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

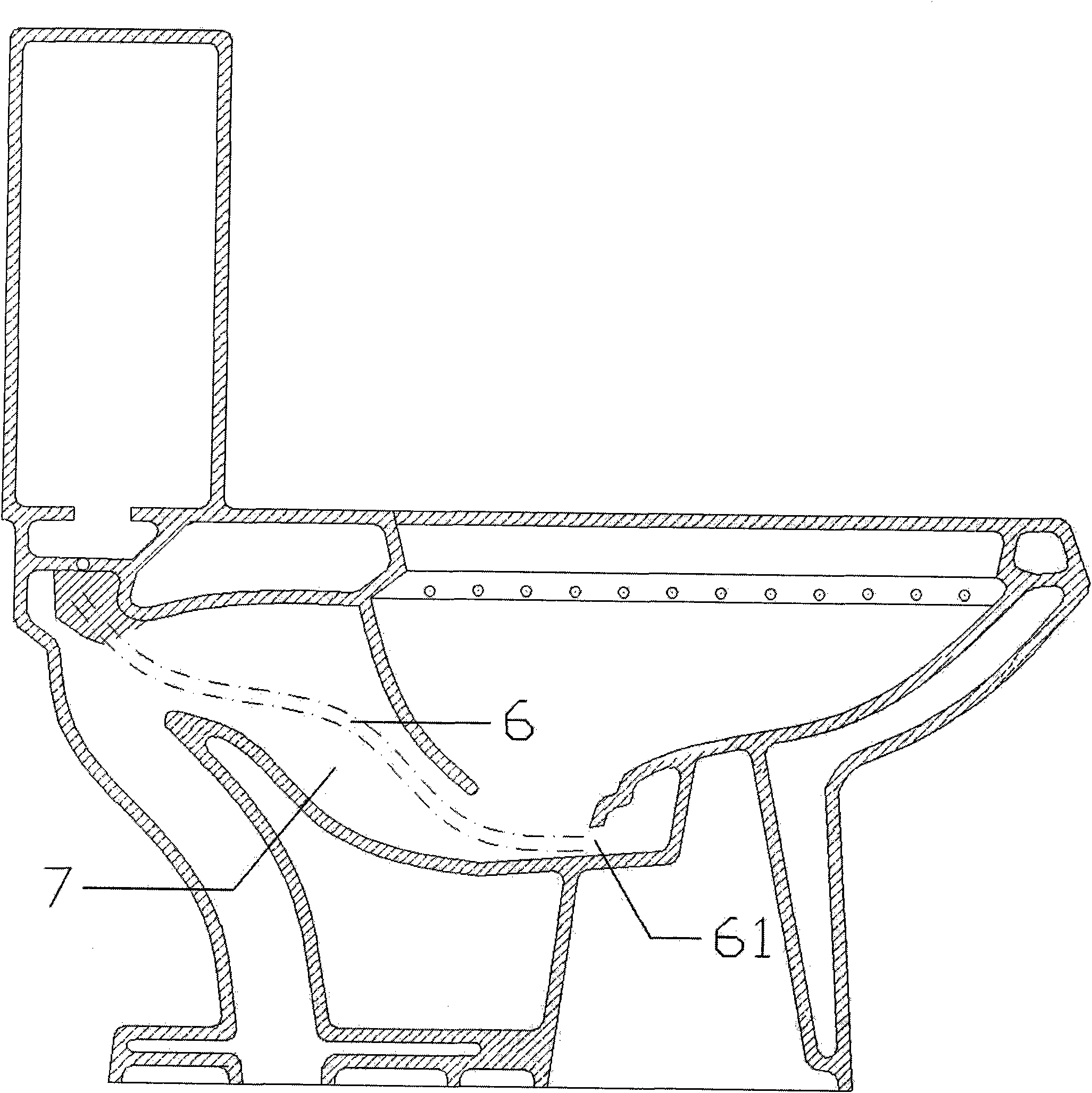

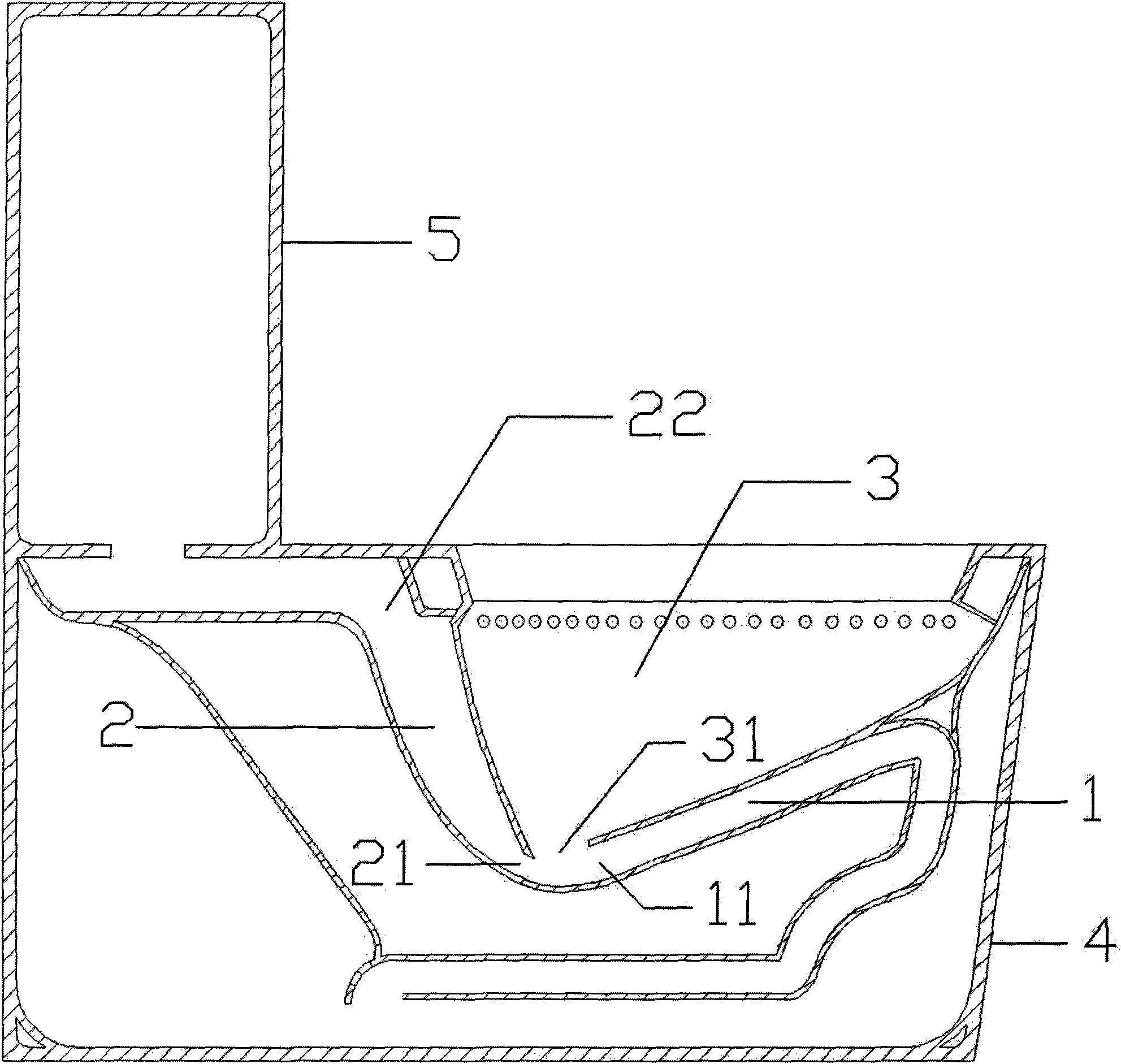

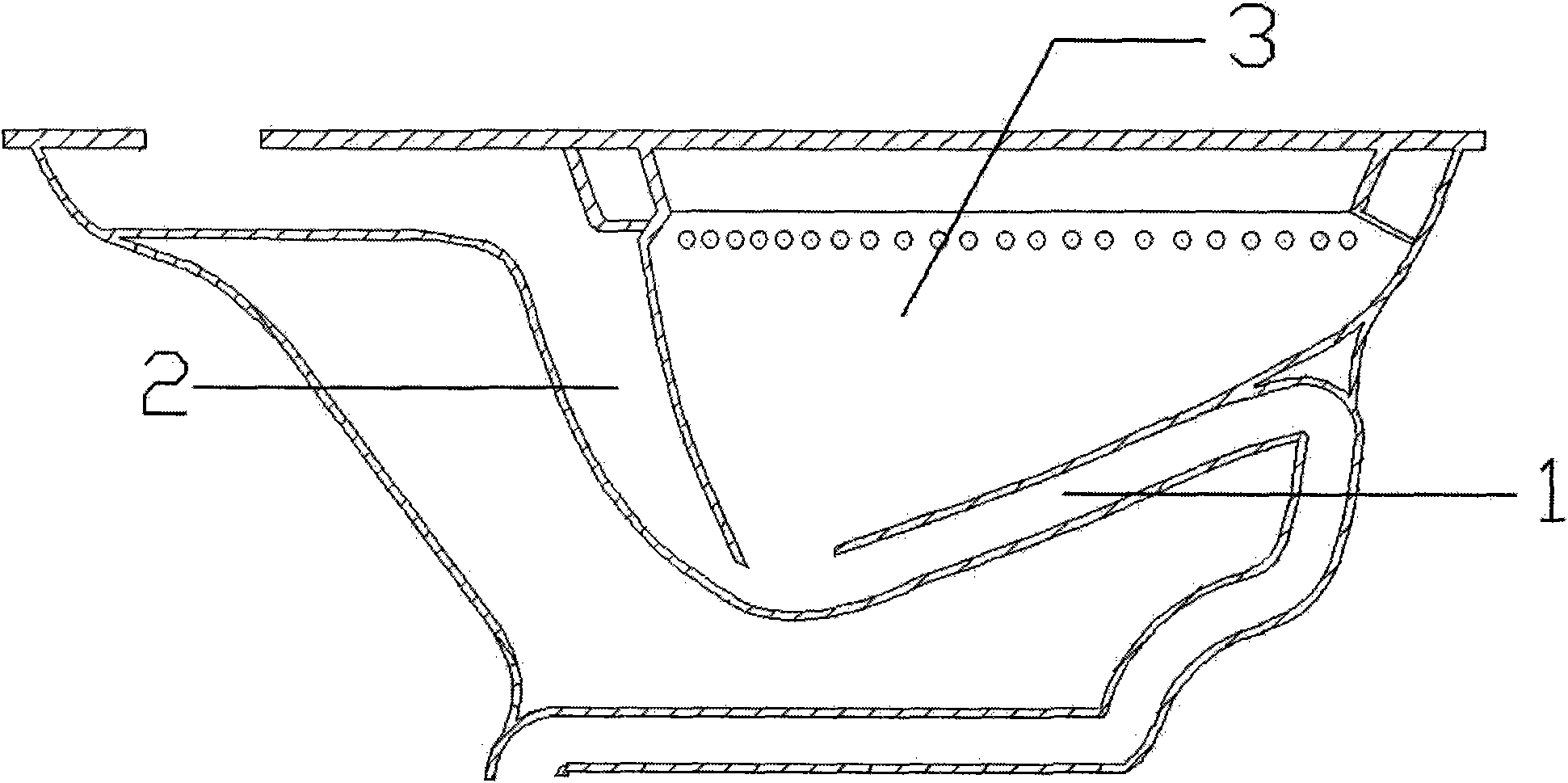

[0026] Example: such as figure 2 As shown, the ceramic water closet with the rear flushing pipe of the present invention includes a seat body 4, a bedpan 3, a sewage bend 1, a flushing pipe 2 and a water tank 5, the outlet 11 of the sewage bend 1 and the sewage outlet of the bedpan 3 31 is connected to the front, the flushing pipe 2 is placed behind the bedpan 3, the protective punching hole 21 of the flushing water pipe 2 is connected to the sewage outlet 31 of the bedpan 3 at the rear, and the protective punching hole 21 is connected to the sewage discharge bend 1 The outlet 11 is opposite; wherein, the flushing pipe 2 is flat, and the cross-sectional area of the nozzle 22 is 20cm 2 , the cross-sectional area of the punching hole 21 is 3cm 2 .

[0027] Such as Figure 3-5 As shown, the above-mentioned ceramic toilet seat with flushing pipe behind is made of bedpan 3, flushing pipe 2 and sewage pipe 1 as the main body, seat body 4, and water tank 5 respectively after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com