Ramie combine harvester

A combine harvester and ramie technology, applied in harvester, mechanical processing, fiber mechanical separation, etc., can solve the problems of high labor intensity and low production efficiency, and achieve high production efficiency, high utilization rate, impurity content and content The effect of low glue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

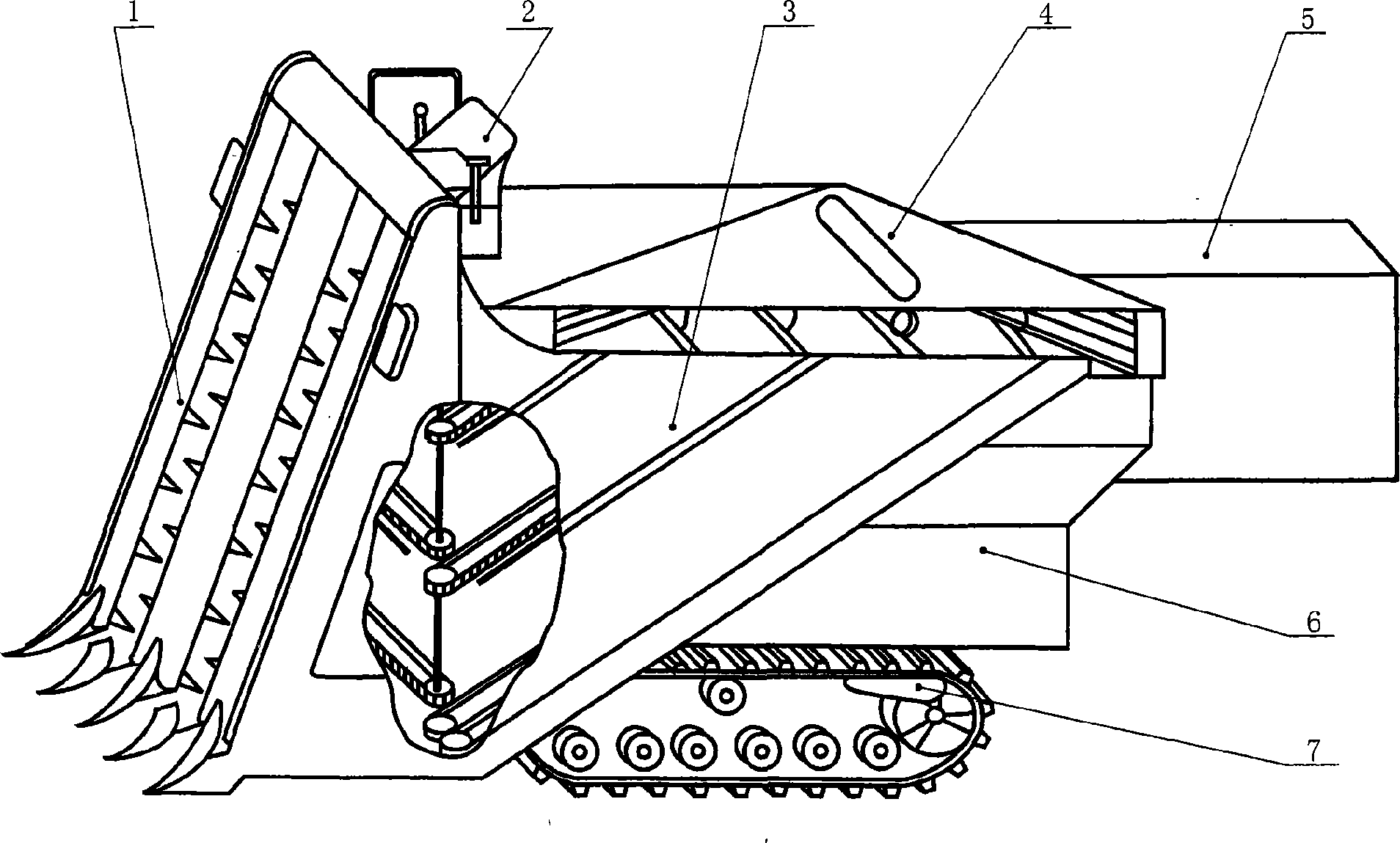

[0010] Such as figure 1 , figure 2 Shown, the chassis section is common to half-feed grain combine harvesters. The vertical header (1) is arranged directly in front, and the despun machine (4) is arranged at the upper rear, and the header (1) and the despun machine (4) are connected through the intermediate conveying device (3) arranged on the left side, The three presented type configuration. Hemp stalks are also The mold direction flows from the header to the denum drum, and finally pulls the fiber out to the rear of the machine.

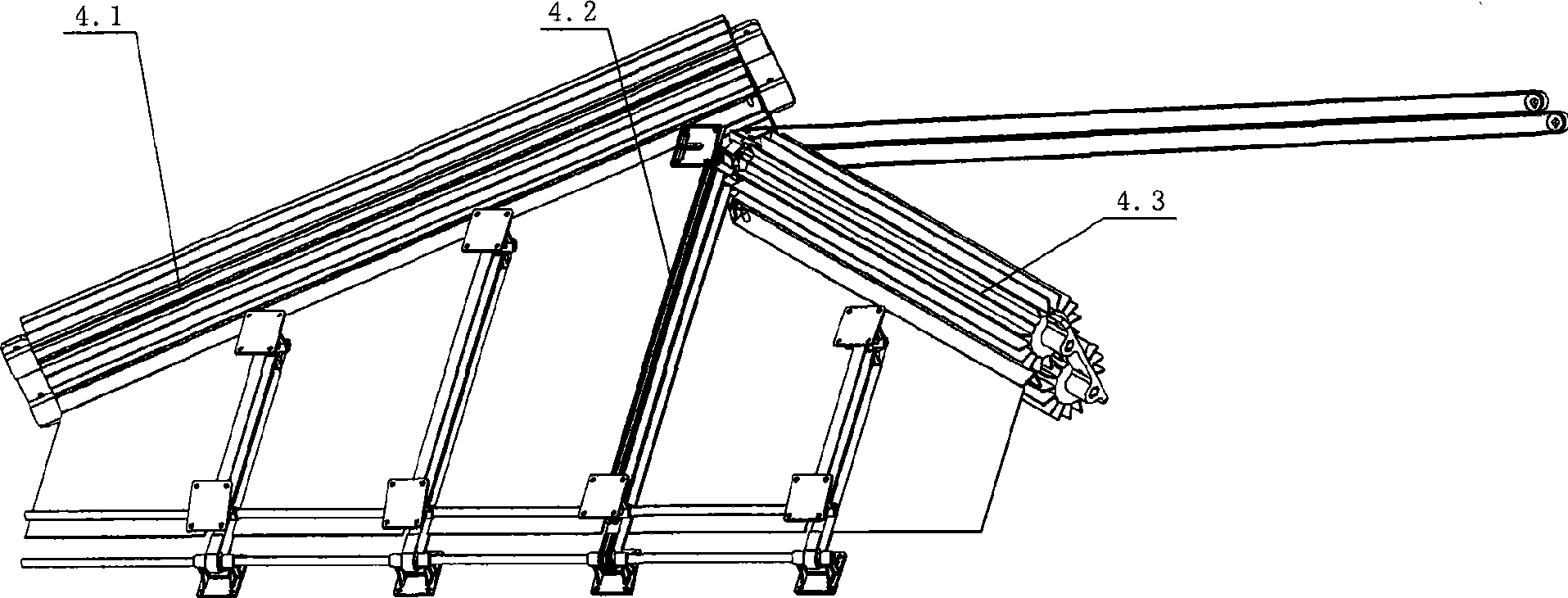

[0011] The cutting platform (1) is composed of a hemp distributor, a hemp supporter, a hemp pulling star wheel, a cutter and a lateral conveyor, and the intermediate conveying device (3) is composed of a synchronous clamping conveying mechanism and a gear-shifting conveying mechanism. The machine (4) is composed of a clamping feeding and pulling device (4.2) and two sets of denumbing mechanisms (4.1, 4.3) arranged in the front and rear acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com