Abrasive grain flow polishing device with vane wheel

A processing device and blade wheel technology, applied to grinding/polishing equipment, impellers, rotor blades, etc., to achieve high polishing precision, improved efficiency, and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

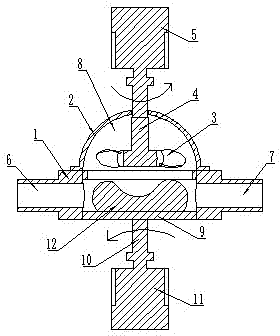

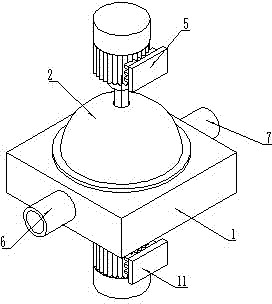

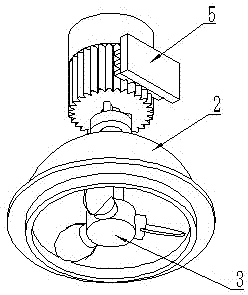

[0017] to combine Figure 1~4 , an abrasive flow polishing device with a vane wheel, including a box body 1, a cover body 2 and a vane wheel 3; a rotating device is provided at the center of the box body 1, and the rotating device includes a turntable 9, a connecting shaft 10, a motor 11, and a turntable 9 Installed in the casing 1, the motor 11 is installed outside the casing 1, the motor 11 is connected to the turntable 9 through the connecting shaft 10, and the workpiece 12 is installed on the turntable 9.

[0018] The cover body 2 is a hemispherical cover body, and the cover body 2 is set on the top of the box body 1, and a sealed polishing chamber 8 is formed between the cover body 2 and the inner cavity of the box body 1, and the two sides of the box body 1 are respectively equipped with abrasive particle inlets 6 And the abrasive grains flow out of the jet 7, the abrasive grains into the jet 6 and the abrasive grains out of the jet 7 communicate with the polishing chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com