Abrasive water jet processing machine

a technology of abrasive water jet and processing machine, which is applied in the direction of abrasive blasting machine, grinding/polishing apparatus, manufacturing tools, etc., can solve the problems of degrading quality, harmful effect, and degrading quality of processing, so as to effectively prevent the backflow of abrasive supply tubes, the effect of increasing the pressure in the abrasive supply tub

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

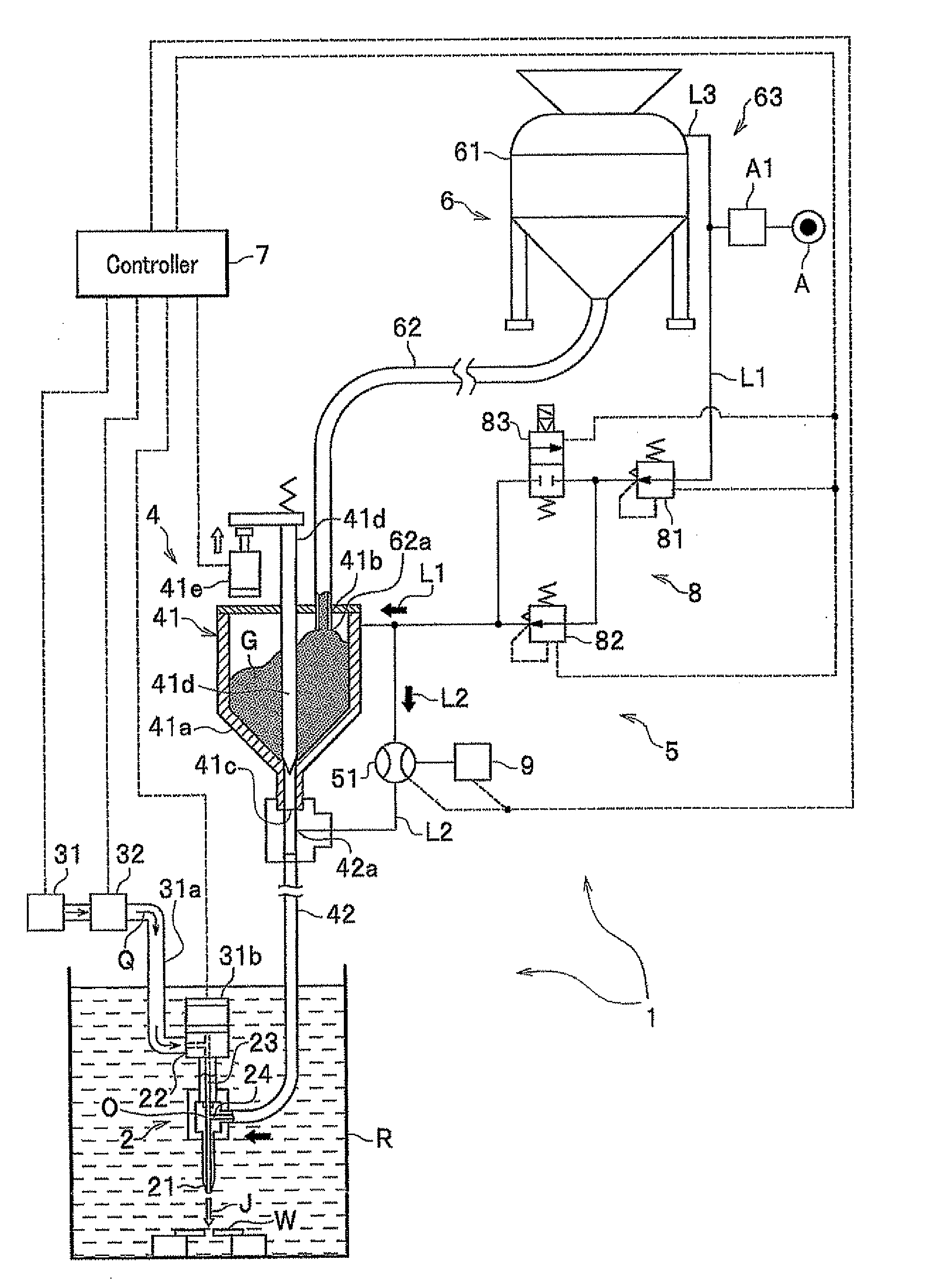

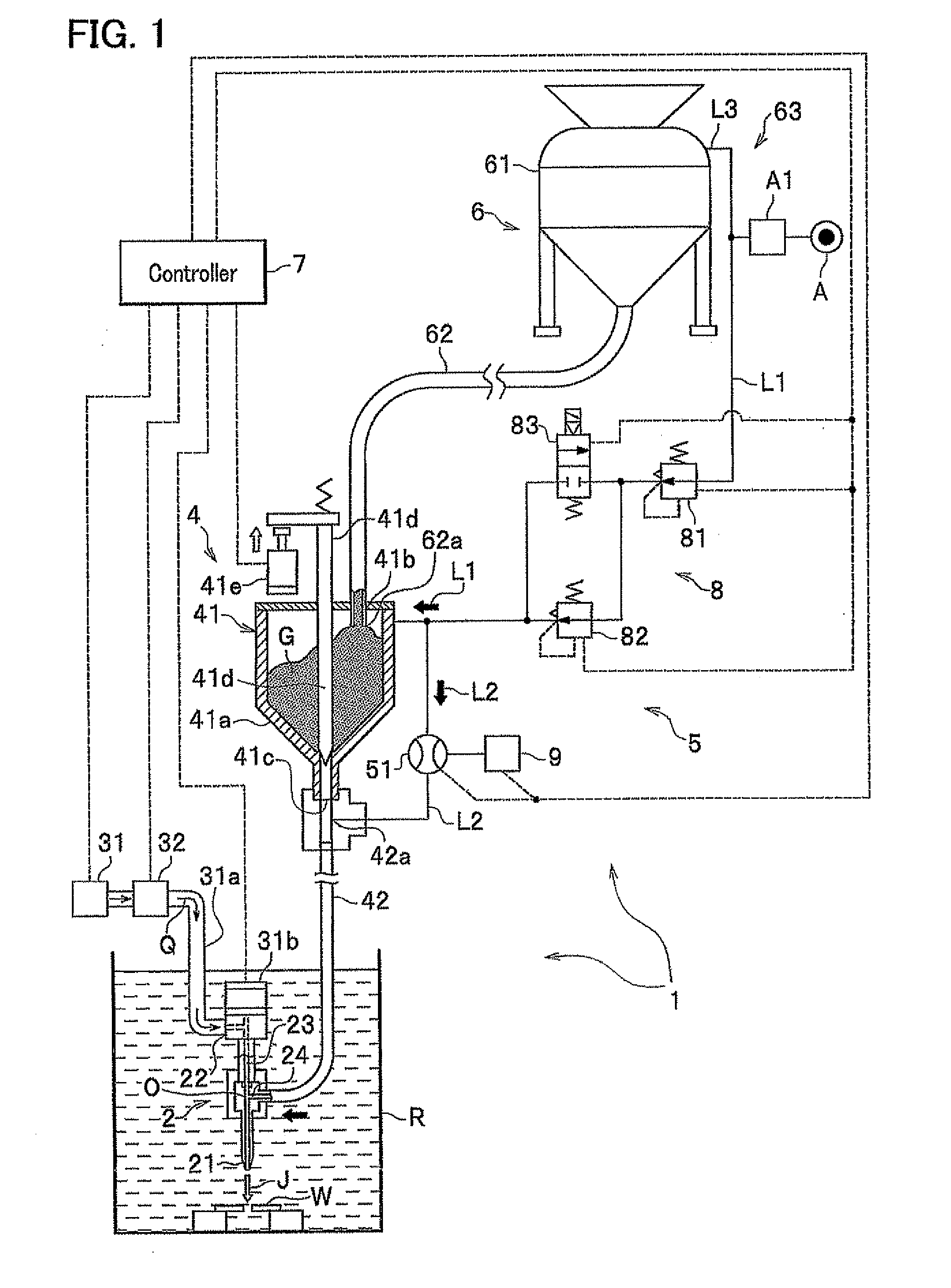

[0029]Here will be in detail described an abrasive water jet processing machine 1 according to an embodiment of the present invention with reference to the drawings as needed.

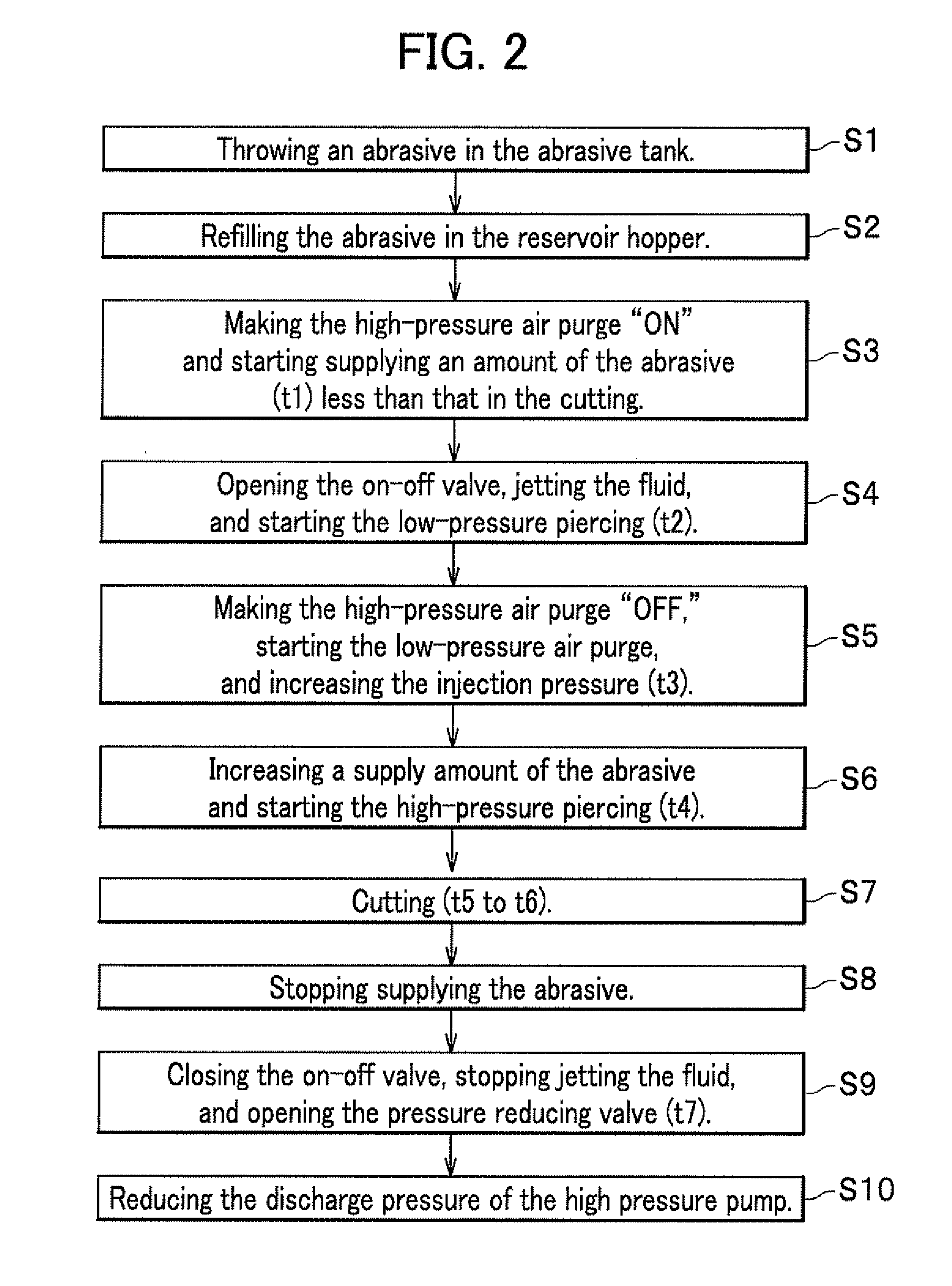

[0030]The abrasive water jet processing machine 1 is a processing apparatus, as shown in FIG. 1, for mixing an abrasive G in a fluid Q, jetting an abrasive water jet J from a nozzle 21 attached to a nozzle unit 2, and cutting a workpiece W clamped in water of a processing bath R.

[0031]The abrasive water jet processing machine 1 has a function of performing a piercing, which is a preceding process of a cutting, for forming a penetration hole, and a function of performing the cutting of various and even complicated shapes and the like with moving the abrasive water jet J that penetrates the workpiece W by the piercing; and the machine 1 can perform a universal various-shape processing such as a honeycomb shape and a gear shape with respect to diverse materials such as stainless steel, Monomer Casting nylon, CFRP,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| flow pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com