Online high-pressure water-jet blasting surface cleaning system

A high-pressure water jet, surface cleaning technology, applied in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc., can solve problems such as easy blockage of abrasive supply pipes, no automatic recovery of abrasives, and poor cleaning quality consistency. To achieve the effect of less abrasive consumption, uniform abrasive supply, and elimination of wear of conveying pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

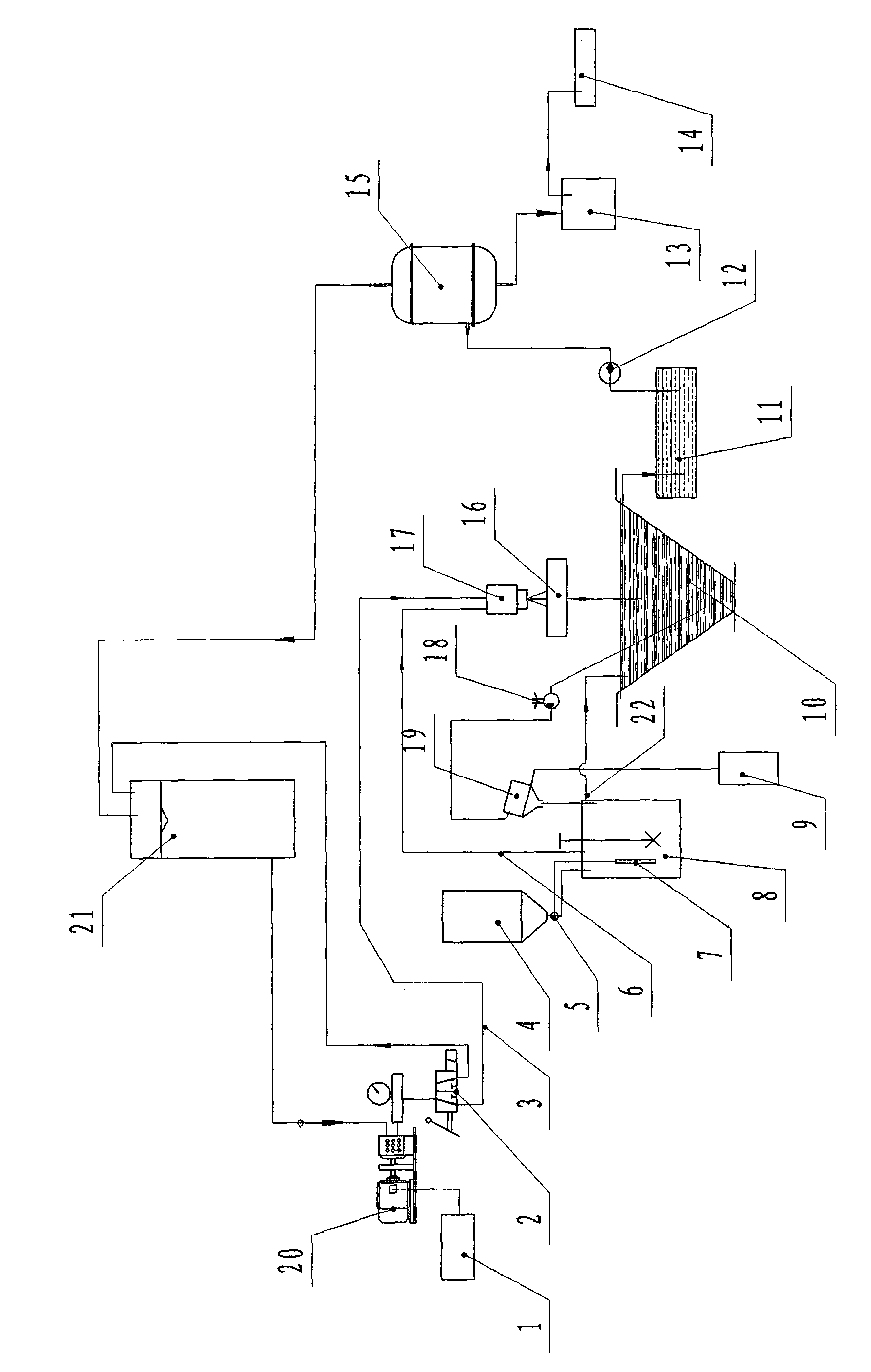

[0020] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0021] Such as figure 1 As shown, the online high-pressure water jet blasting surface cleaning system of the present invention includes a high-pressure water supply mechanism, an abrasive supply mechanism and a nozzle 17, and the high-pressure water supply mechanism and the abrasive supply mechanism are all connected to the input end of the nozzle 17, and the nozzle 17 is located at Above the workpiece 16 to be sprayed, and below the workpiece 16 to be sprayed, an abrasive collection pool 10 is built to collect the sprayed abrasive. The output end of the abrasive collection tank 10 is divided into two paths, one path is connected to the input end of the abrasive material sorting device 19 through the abrasive circulation conveying device 18 and the pipeline, and the other path is connected to the input end of the waste water treatment cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com