Abrasive automatic feeding device and using method

An automatic feeding and abrasive technology, which is applied in the direction of abrasive feeding devices, abrasives, metal processing equipment, etc., can solve problems such as the difficulty of adding abrasives to the jet, and achieve the effects of saving manpower and time, convenient operation, and avoiding circuit problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

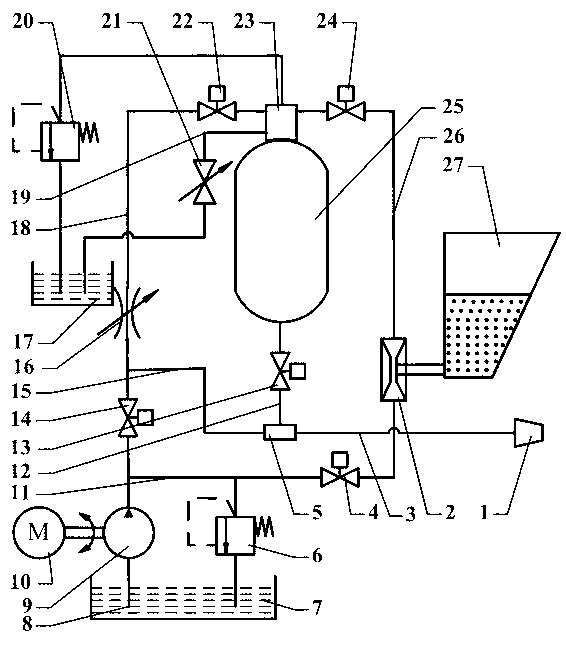

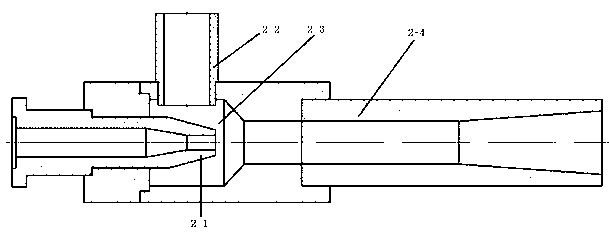

[0026] see figure 1 , the abrasive material automatic supply device of the present invention design mainly is made of feeding hopper 27, jet pump 2, high-pressure abrasive tank 25, valve seat 23 installed in high-pressure abrasive tank 25 top and mixing chamber 5 of the bottom.

[0027] The valve seat 23 is connected with a Gaza pipeline 26, a first high-pressure water pipeline 18, a low-pressure water pipeline 19 and a safety valve 20;

[0028] The mixing chamber 5 is connected with a second high-pressure water pipeline 15 , an abrasive pipeline 12 and an abrasive water jet pipeline 3 .

[0029] The inlets and outlets and the functional components are connected by high-pressure pipelines, and the pipelines are provided with high-pressure ball valves 21, throttle valves 16, and first to fifth pneumatic ball valves 22, 14, 13, 4, 24, specifically The connection relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com