Automatic tunnel drilling machine and method

A technology for drilling machines and tunnels, applied in drilling equipment and methods, tunnels, and earth-moving drilling, etc., can solve the problems of large demand for installation holes in the inner wall of the tunnel, great damage to the health of construction workers, and poor environmental conditions. The working environment is clearly visible, the visibility is guaranteed, and the construction difficulty is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

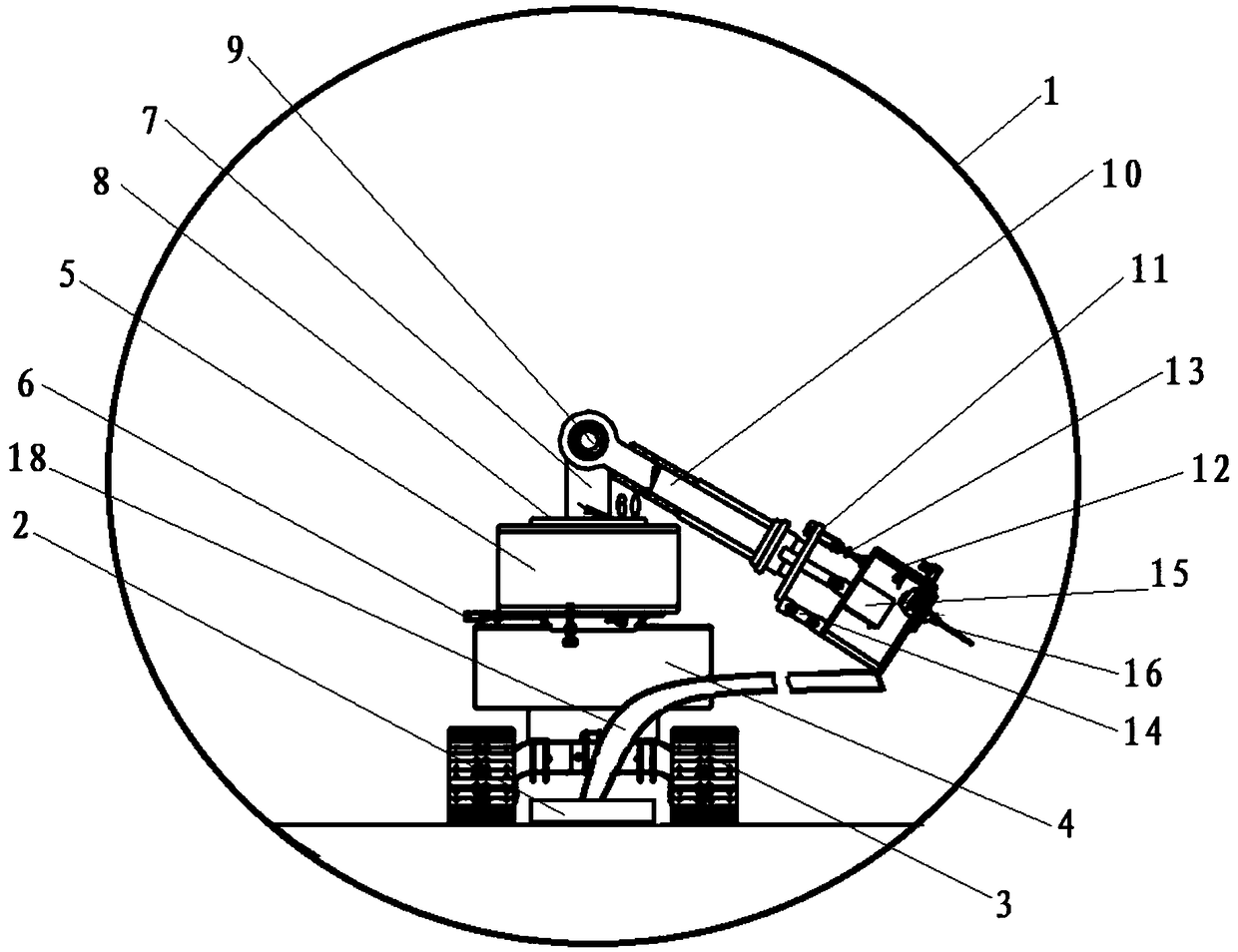

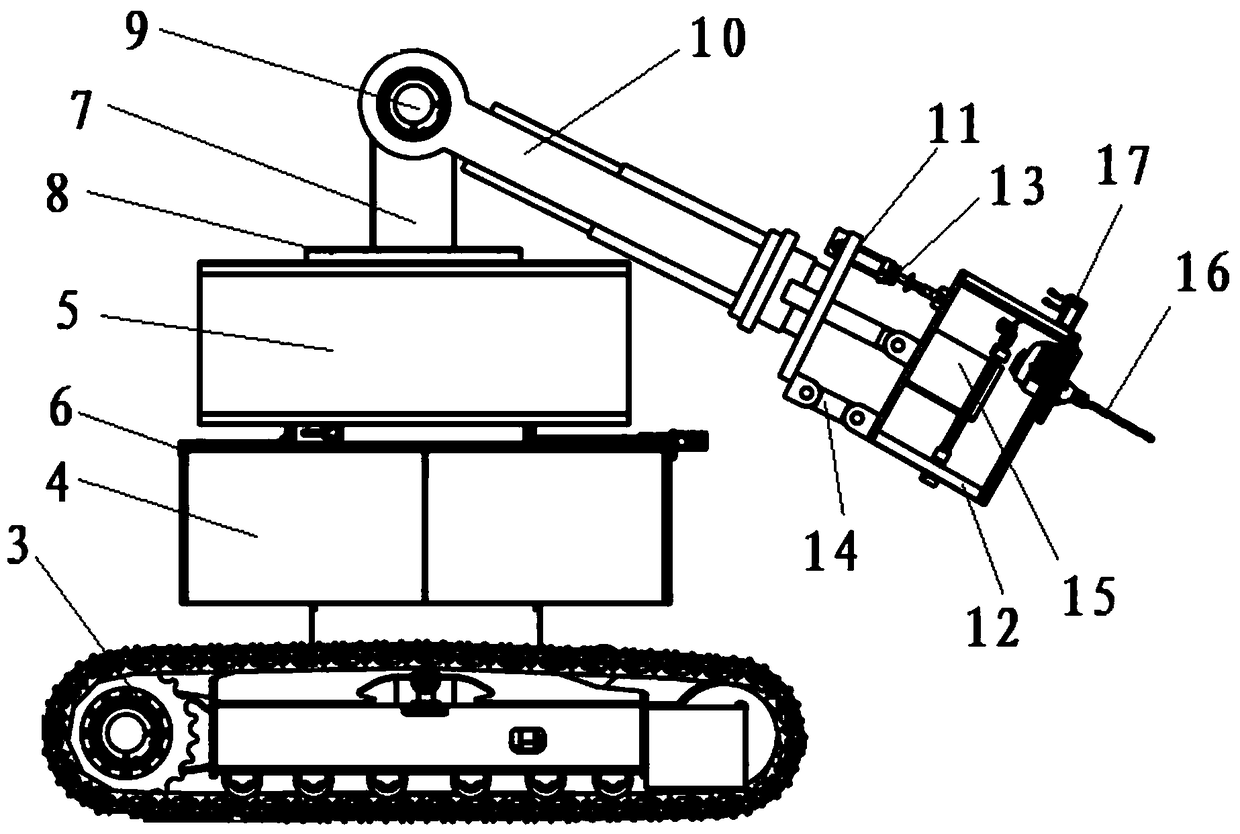

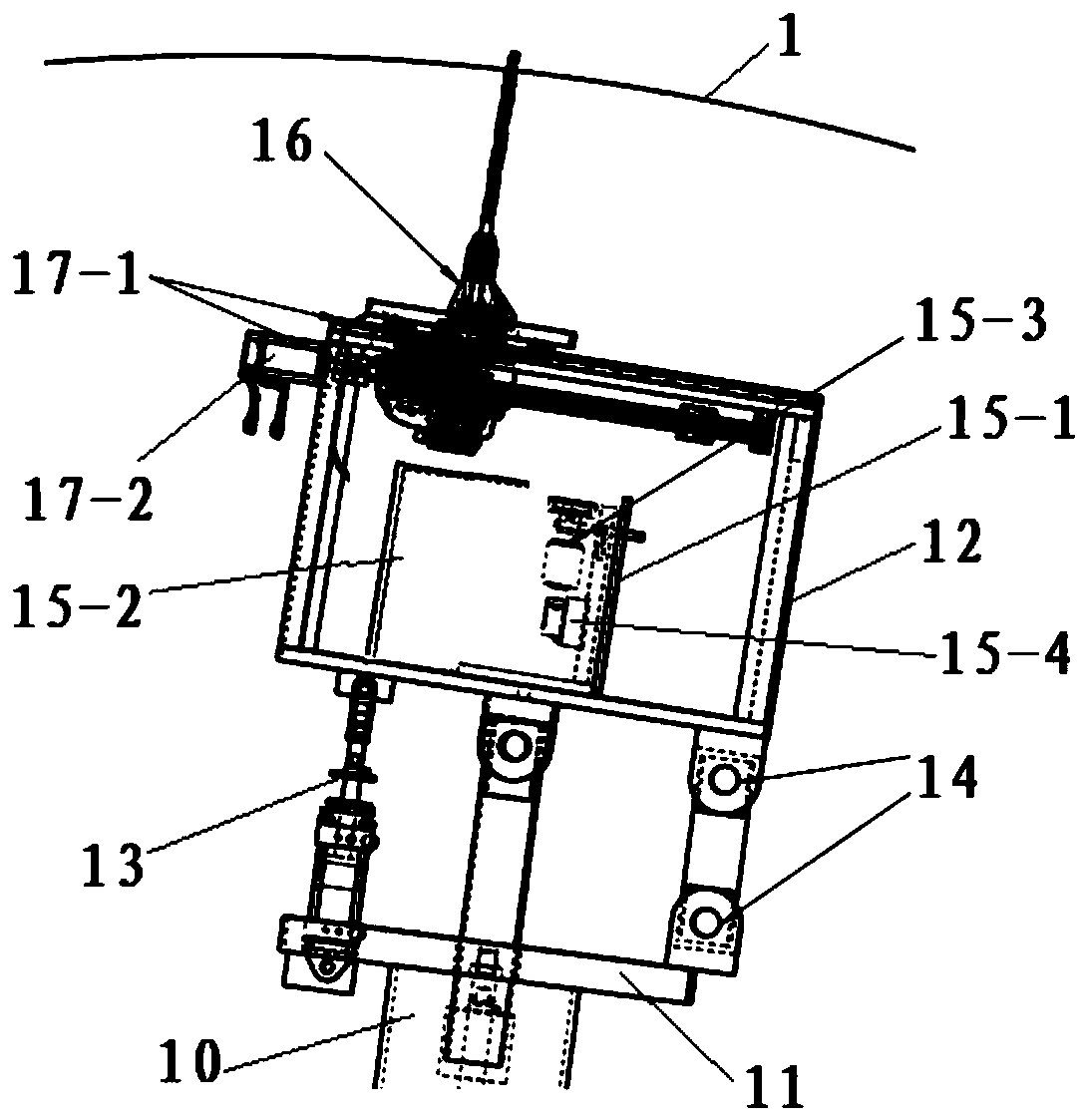

[0062] like Figure 1 to Figure 5 As shown, a tunnel automatic drilling machine according to the present invention includes a crawler vehicle chassis 3, a control support box 4, a hydraulic control box 5 and a central support shaft 7 installed sequentially from bottom to top, and the top of the central support shaft 7 is installed There is a horizontal shaft 9, the fixed end of the main oil cylinder 10 is installed on the two ends of the horizontal shaft 9, the plunger end of the main oil cylinder 10 is hinged with a mounting frame 12 for installing a positioning detection mechanism 15 and an electric drill trimmer 17, and the electric drill 16 is fixedly installed on the On the electric drill trimmer 17, the plunger end of the main oil cylinder 10 is fixedly fitted with a mount 11, and the mount 11 is provided with an inclination adjustment hydraulic cylinder 13 for adjusting the angle of the mount 12, the base of the mount 11 and the mount 12 A connecting hinge 14 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com