A detection method for types of cookers and an electromagnetic heating apparatus

A technology of electromagnetic heating device and detection method, which is applied in the detection of pot type and the field of electromagnetic heating device, and can solve the problems such as difficult to realize electromagnetic heating treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

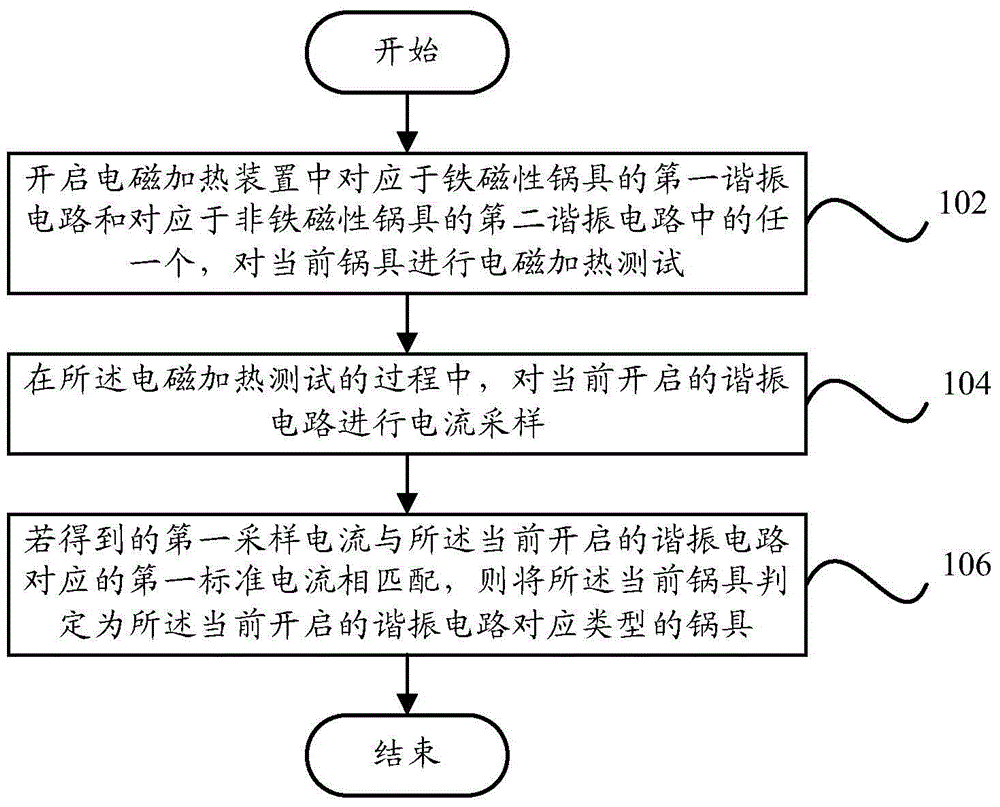

Method used

Image

Examples

Embodiment 1

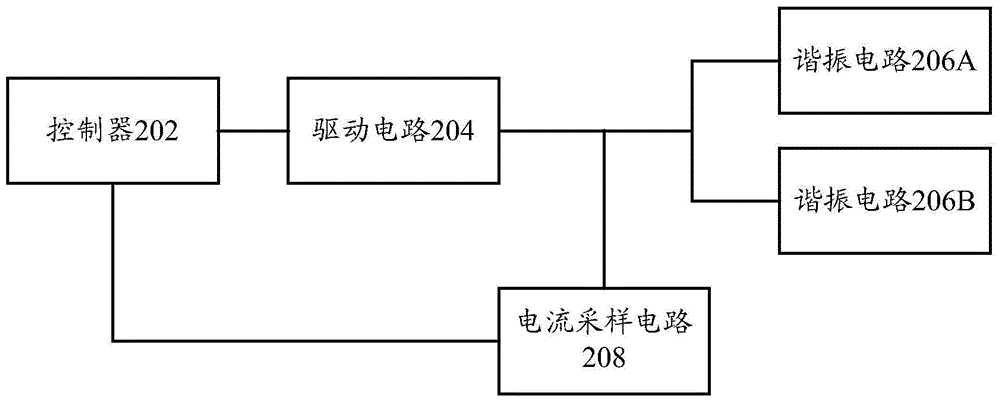

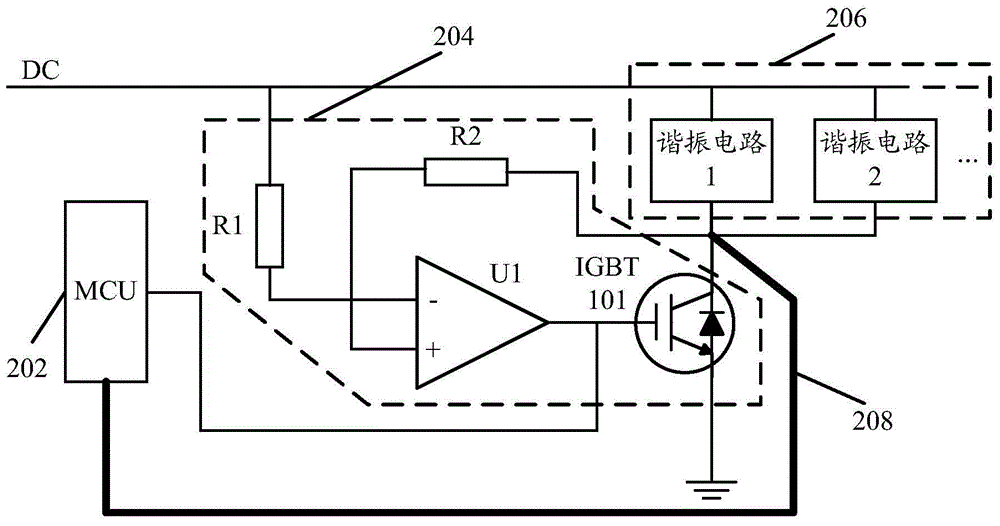

[0120] image 3 for figure 2 A schematic diagram of the circuit structure of an implementation mode of the illustrated embodiment.

[0121] Such as image 3 As shown, the resonant circuit 206 includes a resonant circuit 1, a resonant circuit 2, etc., corresponding to figure 2 Resonant circuit 206A and resonant circuit 206B are shown, among others.

[0122] Taking the resonant circuit 1 as an example, its first end is connected to a DC power supply, and its second end is connected to the collector of the IGBT101 in the driving circuit 204; the driving circuit 204 includes a resistor R1, a resistor R2 and a comparator U1, wherein the resistor R1 One end of resistor R2 is connected to the above-mentioned DC power supply, the other end is connected to the inverting end of comparator U1, one end of resistor R2 is connected to the second end of resonant circuit 1, and the other end is connected to the non-inverting end of comparator U1, comparator U1 The output terminal of is ...

Embodiment 2

[0129] Figure 4A for figure 2 A schematic diagram of the circuit structure of an implementation mode of the illustrated embodiment.

[0130] Such as Figure 4A As shown, the controller 202 may specifically be an MCU.

[0131] Specifically, the driving circuit 204 can realize the driving control of the resonant circuit 206 under the control of the MCU through the IGBT201, the IGBT202 and the corresponding IGBT control chips U102, U103, etc.

[0132] Among them, one end of the IGBT control chip U102 is connected to the MCU, and the other end is connected to the gate of the IGBT201, and the collector of the IGBT201 receives the AC signal input by the PFC power supply; one end of the IGBT control chip U103 is connected to the MCU, and the other end is connected to the IGBT202 The gate of the IGBT202 is connected to the emitter of the IGBT201, and the electrical signal is output to the resonant circuit 206.

[0133] The resonant circuit 206 specifically includes: an inductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com