High-speed preparation device and process of centrifugal electrostatic spinning nanometer twisted yarns

A preparation device, electrospinning technology, applied in the field of centrifugal electrospinning nano-twisting high-speed preparation device, can solve the problems of low production efficiency, poor orientation controllability, complex twisting process, etc., and achieve the effect of increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

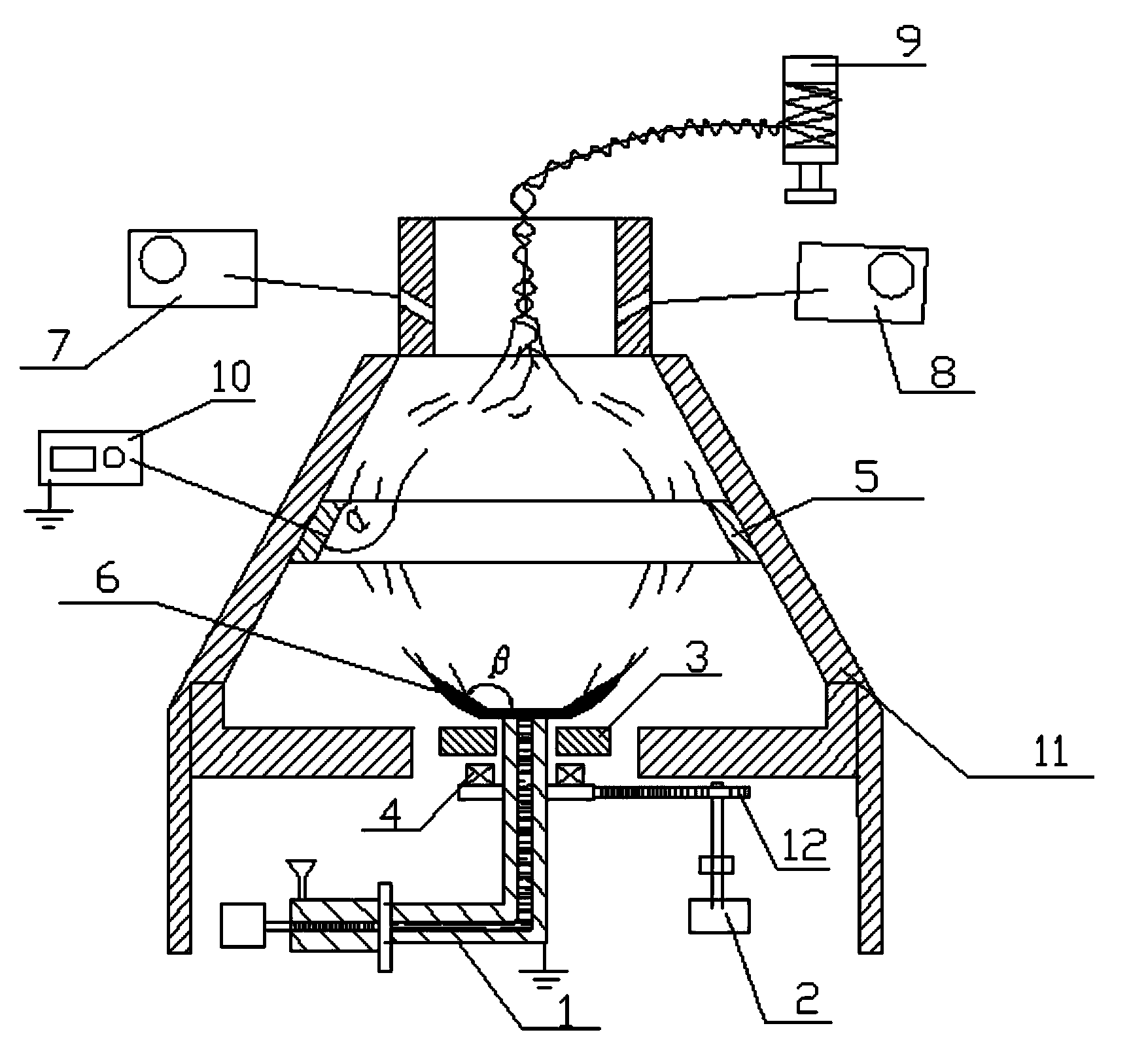

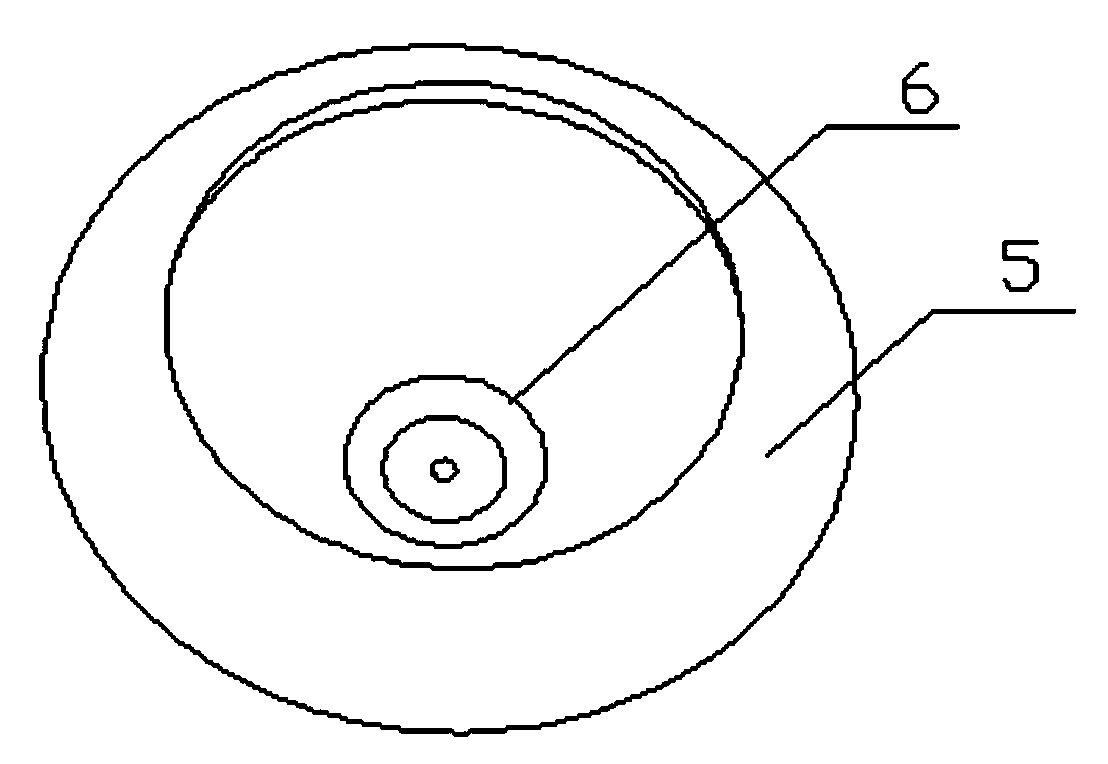

[0018] The invention discloses a high-speed preparation device for centrifugal electrostatic spinning twisted yarn. The schematic diagram of the device is as figure 1 As shown, it mainly includes a feeding device 1, a centrifugal rotating umbrella nozzle 6, a spinning body composed of a cone ring with a hole electrode 5, and a device for producing twisted yarn. Electromagnetic heating ring 3, bearing 4, cone ring with hole electrode 5, centrifugal rotating umbrella nozzle 6, air compressor 7, cyclone vacuum generator 8, roller receiving device 9, high-voltage electrostatic generator 10 and frame 11. The motor 2 is fixed on the bottom of the box, and drives the centrifugal rotating umbrella-shaped nozzle to rotate at high speed through the synchronous toothed belt 12 and the bearing 4. The electromagnetic heater 3 is located around the rotating body of the nozzle, and the air compressor 7 and the cyclone vacuum generator 8 are placed The upper end of the device has a circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com