Tobacco suction system based on electromagnetic heating

A smoking system and electromagnetic technology, applied in the field of tobacco smoking system, can solve the problem of late start of new cigarettes, and achieve the effects of preventing heat loss, simple structure and easy replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

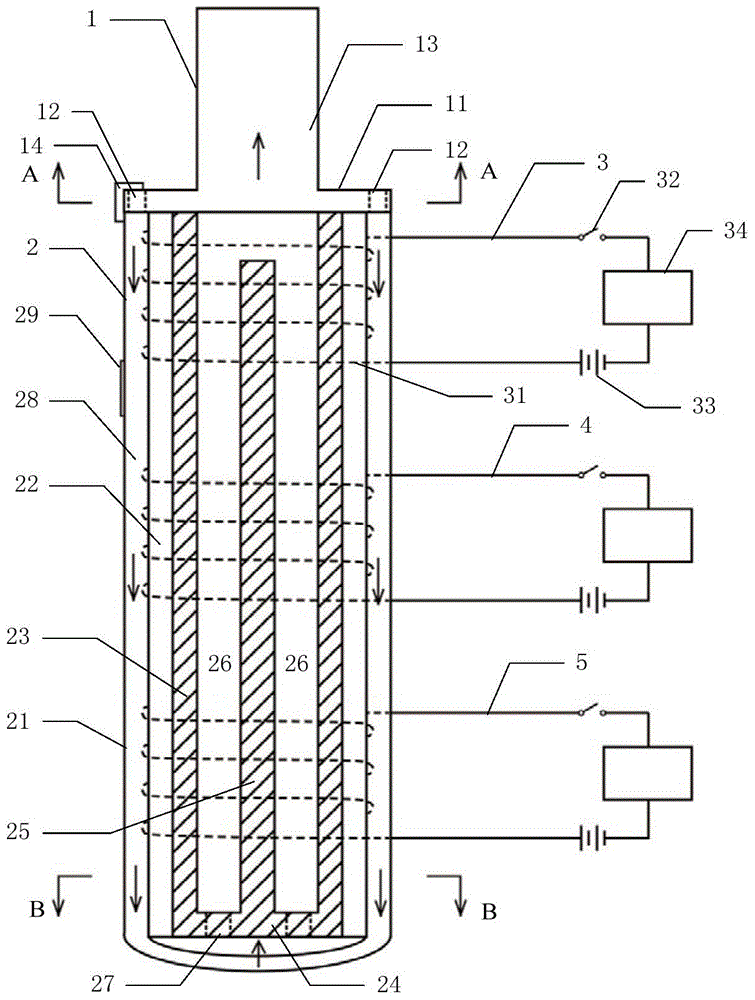

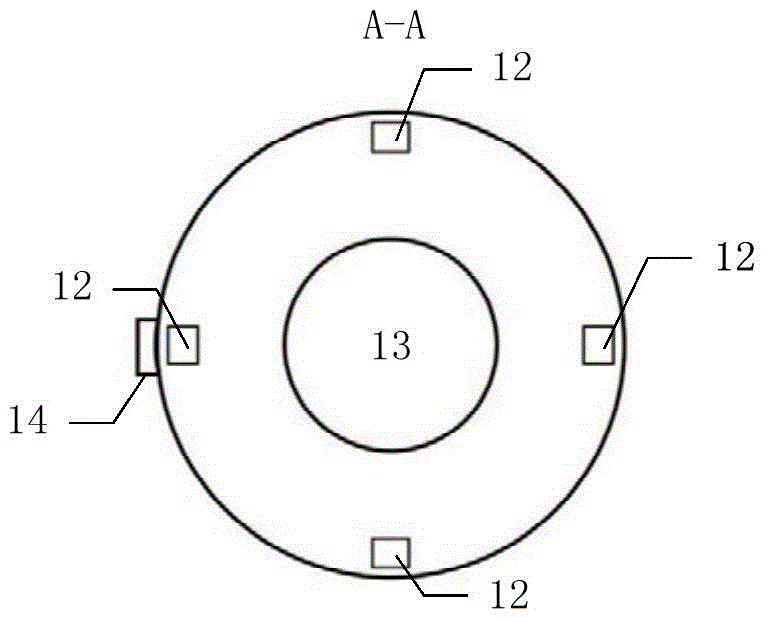

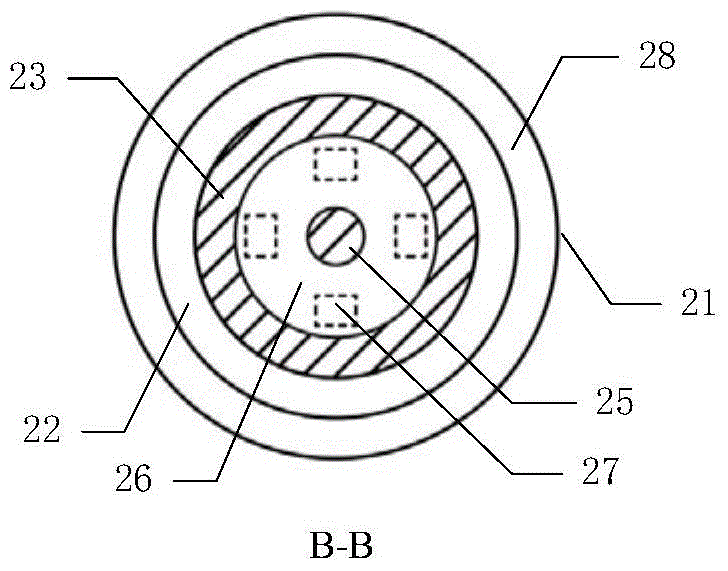

[0040] Such as Figure 1~3 As shown, a tobacco suction system based on electromagnetic heating is suitable for non-combustion heating of tobacco powder, shredded tobacco and circular tobacco products. It includes an end cap 1, a heater 2 and an electromagnetic induction system. The present invention realizes the heating of the heater 2 through the electromagnetic induction system, that is, the tobacco inside the heater 2 can be heated by the heater 2 . The end cover 1 is detachably connected to the heater 2, so as to place or replace tobacco. Specifically, the end cap includes a round cap 11 and a filter tip 13, the round cap 11 is cylindrical as a whole, the filter tip 13 is arranged on the round cap 11, the filter tip 13 is also cylindrical overall, and the The central axis of the filter tip 13 coincides with the central axis of the dome 11 . The center of the round cover 11 has a through hole, that is, the cross section of the round cover 11 is circular, and the smoke in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com