Environment-friendly plastic pipe fusion bonding method

A plastic pipe and bonding technology, applied in the direction of pipe connection layout, pipe/pipe joint/pipe fittings, mechanical equipment, etc., can solve the problems of quality problems, adhesives, environmental pollution, waste and other problems, and achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

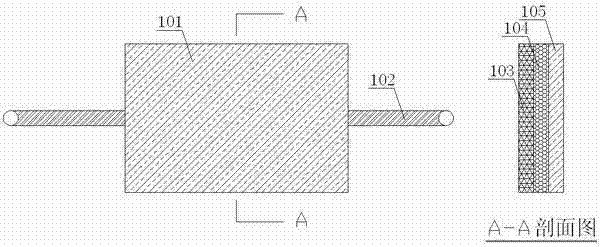

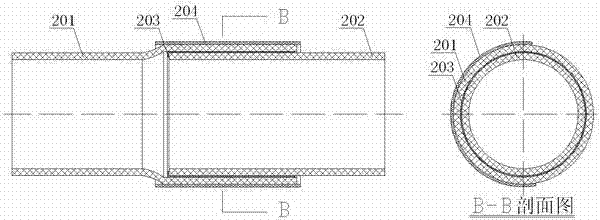

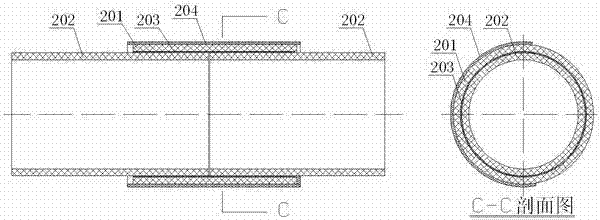

[0024] As shown in Figure 1 and Figure 5, the magnetically permeable material net (203) is made of environmentally friendly and non-toxic magnetically permeable metal materials, including cylindrical, straight and flat shapes with shrinking mesh openings. The magnetically permeable material net (203) has certain longitudinal and lateral expansion and contraction capabilities to facilitate construction.

[0025] The form of fusion bonding is divided into plug-in type, butt-type and plastic sheet bonding.

[0026] Plug-in plastic pipe bonding means that the two plastic pipes that need to be bonded have to go through a treatment process, so that one end of the plastic pipe is a normal pipe diameter, and the other end is heated and flared to become a flared pipe (201 ), when connecting, insert the straight intubation tube (202) at the normal diameter end of one plastic tube into the flared tube (201) at the flared end of the other plastic tube for bonding.

[0027] The butt-joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com