Laser holographic anti-counterfeiting stamping foil containing magnetic encryption information and preparation method thereof

A technology of laser holography and encrypted information, applied in the directions of sealing, ion implantation plating, coating, etc., can solve the problems of damaging the legitimate rights and interests of famous product manufacturers, disrupting the market order, endangering health and the environment, etc., to improve the anti-counterfeiting strength , high anti-counterfeiting strength, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the present invention is specifically described below in conjunction with examples.

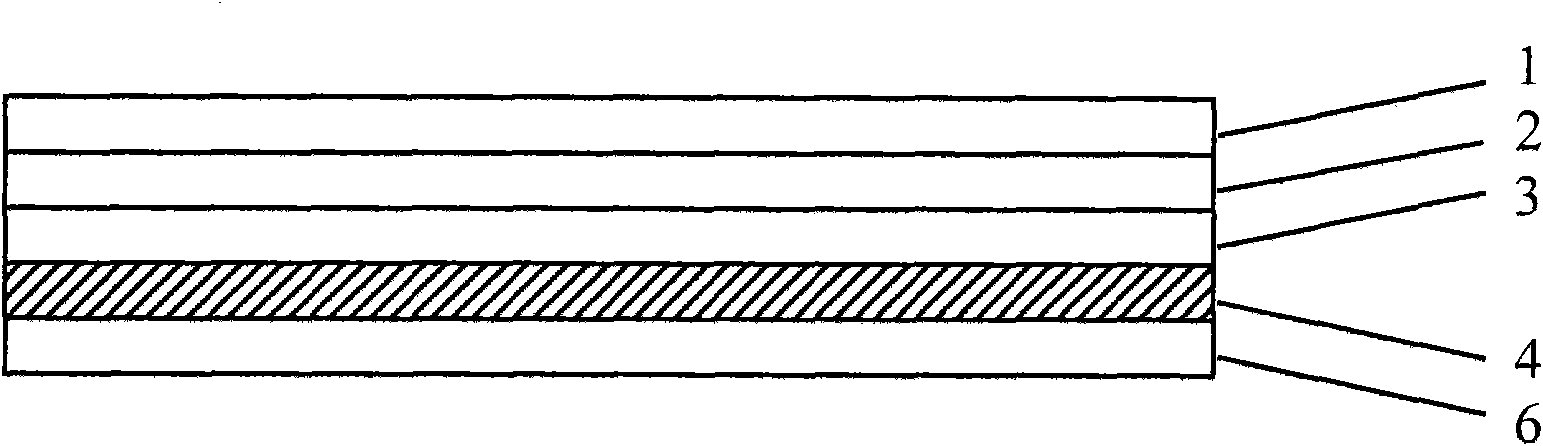

[0032] like figure 1 As shown, the holographic anti-counterfeiting hot stamping foil can usually be composed of five layers of different materials, including a plastic carrier film 1, a separation layer 2, an information recording layer 3, a medium layer 4 and an adhesive layer 6 stacked in sequence.

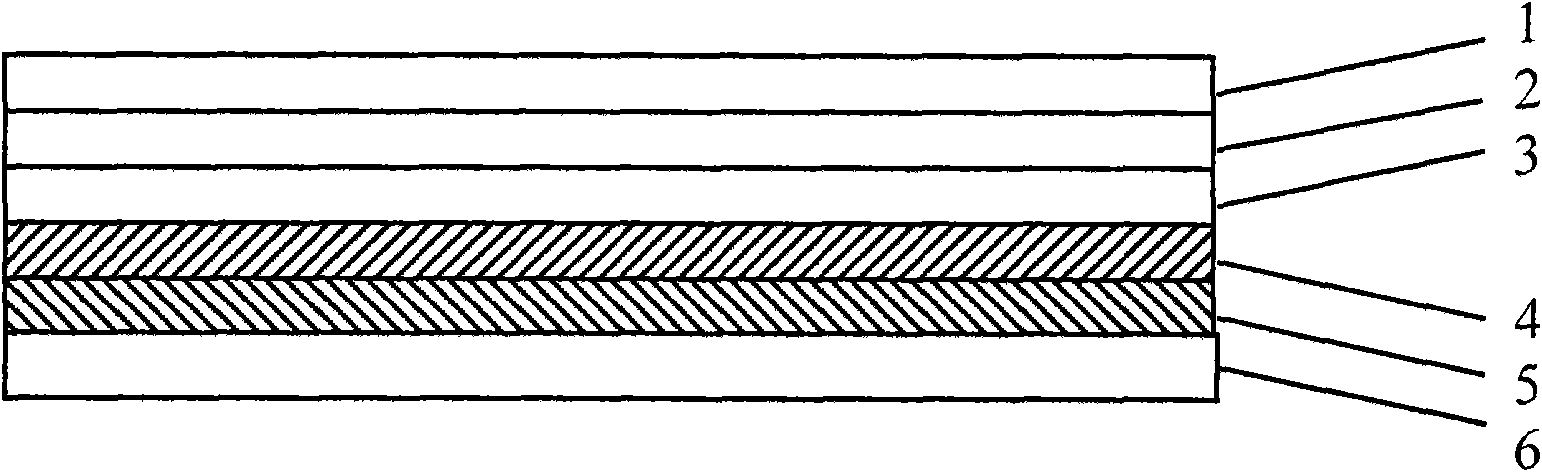

[0033] like figure 2 As shown, the laser holographic anti-counterfeiting hot stamping foil containing magnetically encrypted information of the present invention is composed of six different material layers, including a plastic carrier film 1, a separation layer 2, an information recording layer 3, a dielectric layer 4, and a magnetic coating layer stacked in sequence. 5 and adhesive layer 6.

Embodiment 1

[0035] A high-speed coater is used to uniformly coat a separation layer 2 on a 15 μm PET plastic carrier film 1 at a coating temperature of 120° C. and a speed of 80 m / min. The acrylic resin was evenly coated on the separation layer 2 to form the information recording layer 3 at a coating temperature of 90° C. and a speed of 80 m / min. On the molding machine, the laser holographic information on the metal nickel plate is transferred to the information recording layer 3, so that the information recording layer 3 is provided with the laser holographic information. The molding temperature is 150° C., and the speed is 40 m / min. In a vacuum state, silicon dioxide is plated on the surface of the information recording layer 3 to form a dielectric layer 4 with a thickness of 350 angstroms. A magnetic coating 5 is coated on the dielectric layer 4 at a coating temperature of 120° C. and a speed of 60 m / min. Ethylene-vinyl acetate copolymer resin hot-melt adhesive is coated on the magnet...

Embodiment 2

[0037] A high-speed coater is used to evenly coat the separation layer 2 on the 12 μm PET plastic carrier film 1 with a coating temperature of 120° C. and a speed of 80 m / min. The acrylic resin was evenly coated on the separation layer 2 to form the information recording layer 3 at a coating temperature of 90° C. and a speed of 80 m / min. On the molding machine, the laser holographic information on the metal nickel plate is transferred to the information recording layer 3, so that the information recording layer 3 is provided with the laser holographic information. The molding temperature is 150° C., and the speed is 40 m / min. In a vacuum state, zinc sulfide is plated on the surface of the information recording layer 3 to form a dielectric layer 4 with a thickness of 350 angstroms. A magnetic coating 5 is coated on the dielectric layer 4 at a coating temperature of 120° C. and a speed of 60 m / min. Polyethylene and ethylene copolymer hot-melt adhesives are coated on the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com