Method for producing resin diamond wire

A technology of resin diamond wire and production method, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of affecting the depth of cutting into the workpiece, insufficient height of the diamond edge of the resin diamond wire, and high manufacturing cost, and achieves optimum performance. The effect of edge height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific examples.

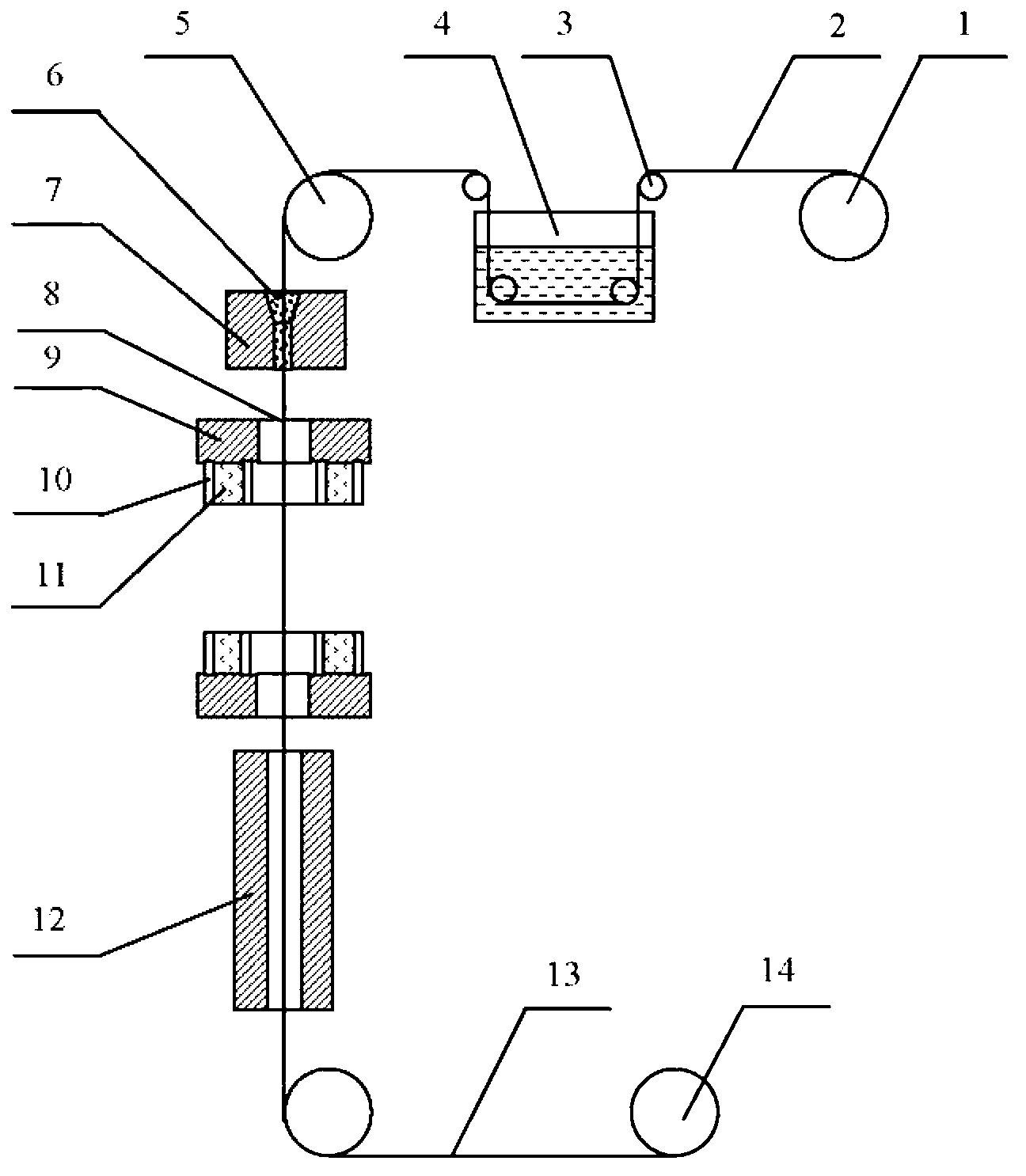

[0026] Such as figure 1 Shown, a kind of production method of resin 17 diamond wire 13, it comprises the following steps:

[0027] 1) Configure mixture 6

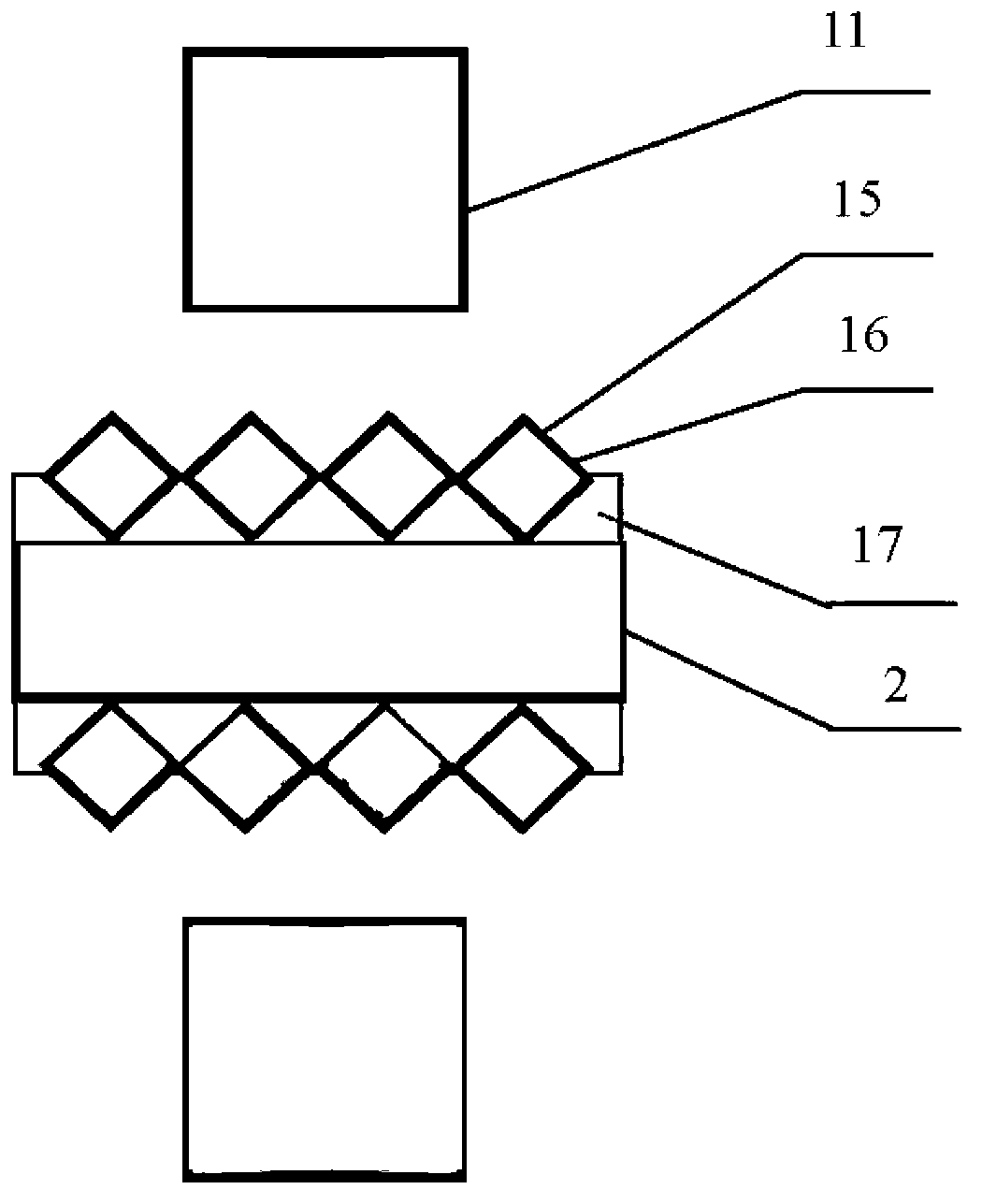

[0028] Evenly mix the diamond 16 abrasive, resin 17 and additives of the surface magnetic coating 15 according to a certain process ratio;

[0029] 2) Coating

[0030] The mixture 6 is subjected to vacuum degassing treatment in a vacuum drying oven, and the prepared resin 17 abrasive mixture is injected into the coating mold 7 by air pressure, and the steel wire 2 passes through the coating mold 7, and the steel wire 2 passes through the coating mold 7. The wire 2 passes through the coating mold 7, so that the mixture 6 is coated on the surface of the steel wire 2; like this, the mixture 6 to be solidified is adhered to the steel wire 2 surface to form a steel wire 2 coated with resin 17 abrasives.

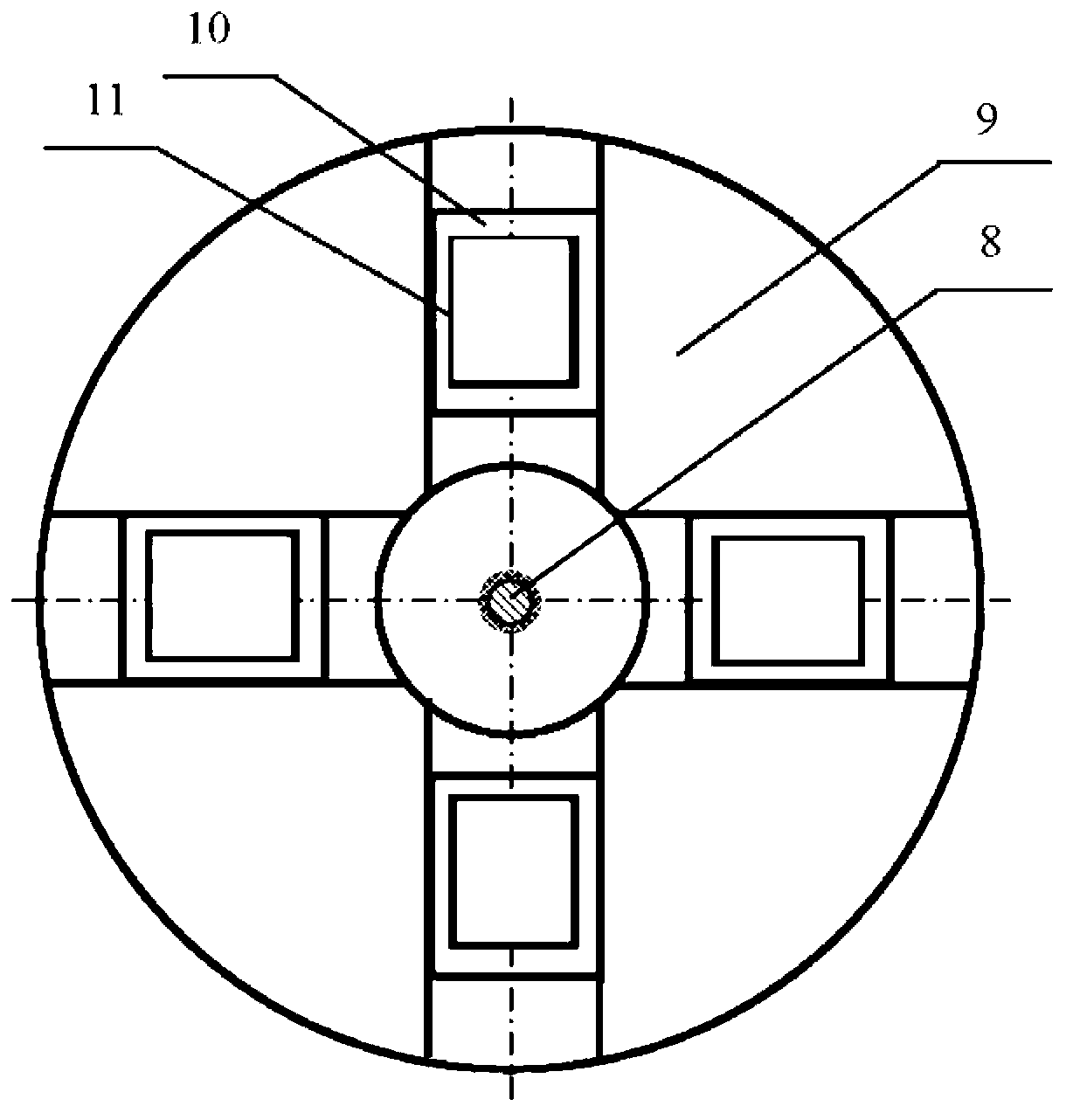

[0031] 3) Adjust the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com