High-viscosity masking paper tape and preparation process thereof

A preparation process, a technology of textured paper, applied in non-polymer adhesive additives, non-polymer organic compound adhesives, adhesives, etc., can solve the problem of poor tensile strength, micro-toxicity, and small application range and other problems, to achieve the effect of strong viscosity, not easy to corrupt, and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

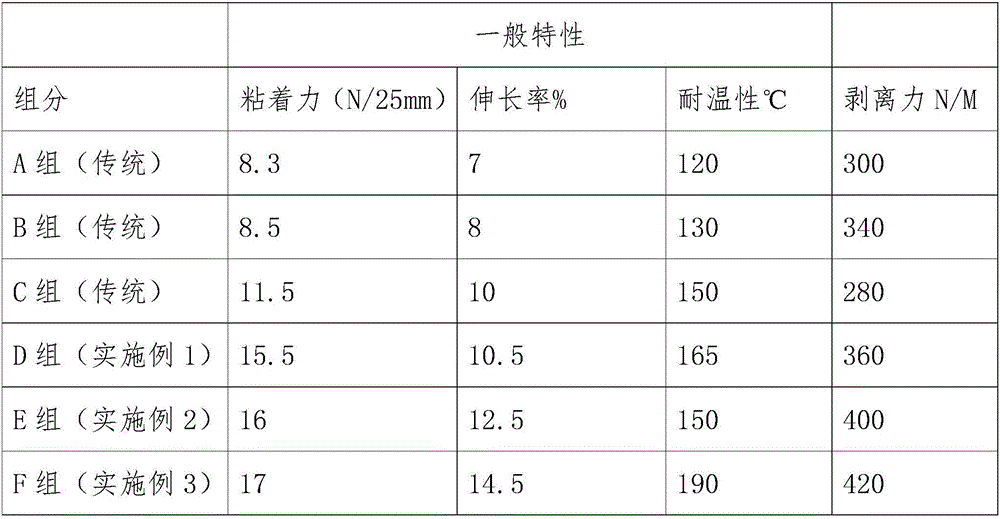

Examples

Embodiment 1

[0032] A preparation process of pressure-sensitive adhesive for high-viscosity masking tape:

[0033] Step 1: According to each group of formulas, it is made of the following raw materials in parts by weight: 60 parts of main rubber, 2 parts of antioxidant, 3 parts of rosin resin, 4 parts of emulsifier, 9 parts of acrylic acid, 3 parts of sodium polyacrylate, propylene butyl 30 parts of acid ester, 2.5 parts of degassing agent, 4 parts of chitosan, 15 parts of acrylamide, 8 parts of propylene glycol methyl ether, 10 parts of dimethyl succinate, 7 parts of crosslinking agent, first take 60 parts of main rubber and propylene Add 15 parts of amide into the reaction kettle for mixing and kneading. The reaction kettle is closed and filled with nitrogen protection, so that the temperature in the reaction kettle rises slowly to 50°C, with an average of 1°C / h, so that the main rubber and acrylamide Perform a mixing reaction, then add 3 parts of sodium polyacrylate and 30 parts of prop...

Embodiment 2

[0043] A preparation process of pressure-sensitive adhesive for high-viscosity masking tape:

[0044] Step 1: According to each formula, it is made of the following raw materials in parts by weight: 80 parts of main rubber, 4 parts of antioxidant, 5 parts of rosin resin, 6 parts of emulsifier, 9 parts of acrylic acid, 3 parts of sodium polyacrylate, propylene butyl 25 parts of acid ester, 1.5 parts of degassing agent, 4 parts of chitosan, 12 parts of acrylamide, 8 parts of propylene glycol methyl ether, 8 parts of dimethyl succinate, 5 parts of crosslinking agent, first take 80 parts of main rubber and propylene Add 12 parts of amide into the reactor for mixing and kneading. The reactor is closed and filled with nitrogen protection, so that the temperature in the reactor rises slowly to 55°C, with an average of 1°C / h, so that the main rubber and acrylamide Perform a mixing reaction, then add 3 parts of sodium polyacrylate and 25 parts of propylene butyrate into the reaction ke...

Embodiment 3

[0054] A preparation process of pressure-sensitive adhesive for high-viscosity masking tape:

[0055] Step 1: According to each formula, it is made from the following raw materials in parts by weight: 70 parts of main rubber, 3 parts of antioxidant, 4 parts of rosin resin, 5 parts of emulsifier, 8 parts of acrylic acid, 2 parts of sodium polyacrylate, propylene butyl 28 parts of acid ester, 1.5 parts of degassing agent, 3.5 parts of chitosan, 13 parts of acrylamide, 7 parts of propylene glycol methyl ether, 9 parts of dimethyl succinate, 6 parts of crosslinking agent, first take 70 parts of main rubber and propylene Add 13 parts of amide into the reaction kettle for mixing and kneading. The reaction kettle is closed and filled with nitrogen protection, so that the temperature in the reaction kettle rises slowly to 53°C, with an average of 1°C / h, so that the main rubber and acrylamide Carry out mixing reaction, then add 2 parts of sodium polyacrylate and 28 parts of propylene b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com