High wear-resisting insulation paper adhesive tape

A technology of insulating paper and adhesive tape, applied in the direction of adhesives, paper/cardboard layered products, adhesive types, etc., can solve the problems of insufficient high temperature resistance, poor wear resistance, easy damage, etc., achieve wear resistance, improve Effects of abrasion resistance and good cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

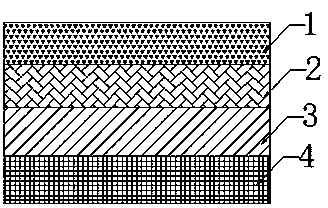

[0019] A highly wear-resistant insulating paper tape, comprising an adhesive layer 1, a rubber layer 2, a paper layer 3 and a wear-resistant layer 4 that are laminated and compounded in sequence from top to bottom, wherein the thickness of the rubber layer 2 is 0.5mm, which is nitrile butadiene The mixed rubber layer obtained by mixing rubber and silicone rubber in a ratio of 3:1, nitrile rubber has excellent oil resistance, wear resistance, heat resistance and strong adhesion, but its disadvantage is poor low temperature resistance. The mixing of silicone rubber can effectively improve its low temperature performance; the paper layer 3 is kraft paper; the wear-resistant layer 4 is a glass fiber cloth layer with a thickness of 50 μm, and the glass fiber cloth layer and the paper layer are adhered to each other. The mixture is bonded together, and the adhesive used is the same as the composition of the adhesive layer 1 .

[0020] The components of the adhesive layer 1 are adhes...

Embodiment 2

[0022] The difference from Example 1 is that the thickness of the rubber layer 2 is 1.5 mm, wherein the mixing ratio of nitrile rubber and silicone rubber is 5:1; the thickness of the glass fiber cloth layer is 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com