Composite high-temperature-resistant PET Meguiar's paper adhesive tape

A micron paper, high temperature resistant technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of weak stickiness of paper tape, poor performance of high temperature resistance, etc., and achieve good adhesion , High heat resistance, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

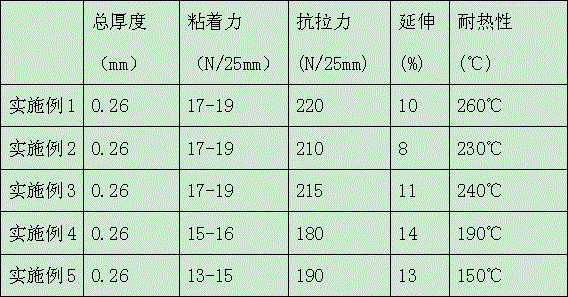

Examples

Embodiment 1

[0024] PET micron paper composite high temperature resistant adhesive tape, including a release agent layer, a paper substrate layer, an adhesive layer, a plastic layer and an adhesive layer arranged in sequence from top to bottom, the paper substrate layer is composed of Micron paper, and the adhesive The layers consist of a silicone adhesive,

[0025] The adhesive layer described in this embodiment is preferably composed of the following components by weight:

[0026] 2 parts of dibenzoyl peroxide, 95 parts of silicone pressure-sensitive adhesive, 3 parts of diisocyanate, 205 parts of acrylate pressure-sensitive adhesive, 60 parts of silicone glue, 2 parts of polymethyltriethoxysilane;

[0027] The plastic layer preferably consists of the following components by weight:

[0028] 70 parts of polyethylene terephthalate, 4 parts of silicone, 2 parts of di-tert-butyl peroxide.

[0029] The preparation method of the above-mentioned PET micron paper composite high temperature re...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 lies in that the content of each component in the plastic layer and the adhesive layer is different.

[0037] The adhesive layer is composed of the following components by weight:

[0038] 1 part of dibenzoyl peroxide, 95 parts of silicone pressure-sensitive adhesive, 4 parts of diisocyanate, 200 parts of acrylate pressure-sensitive adhesive, 60 parts of silicone glue, and 2 parts of polymethyltriethoxysilane.

[0039] The plastic layer is composed of the following components by weight:

[0040] 65 parts of polyethylene terephthalate, 3 parts of silicone, 2 parts of di-tert-butyl peroxide.

Embodiment 3

[0042] The difference between this embodiment and embodiment 1 lies in that the content of each component in the plastic layer and the adhesive layer is different.

[0043] The adhesive layer is composed of the following components by weight:

[0044] 2 parts of dibenzoyl peroxide, 98 parts of silicone pressure-sensitive adhesive, 3 parts of diisocyanate, 205 parts of acrylate pressure-sensitive adhesive, 55 parts of silicone glue, and 2 parts of polymethyltriethoxysilane.

[0045] The plastic layer is composed of the following components by weight:

[0046] 70 parts of polyethylene terephthalate, 3 parts of silicone, 1 part of di-tert-butyl peroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com