Heat-resistant coating tensile shear strength test model and production method thereof

A technology of tensile shear strength and test model, which is applied in the field of tensile shear strength test model of heat-resistant coating, can solve the problems of unevenness, loss of adhesive thickness, etc., and achieves a simple production method and improves stability and reliability. The effect of ensuring the thickness and compactness of the adhesive layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

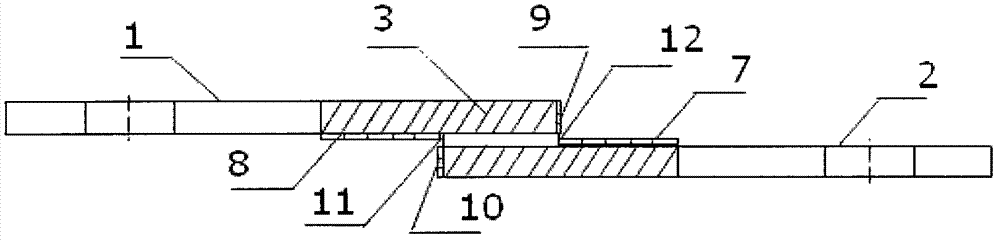

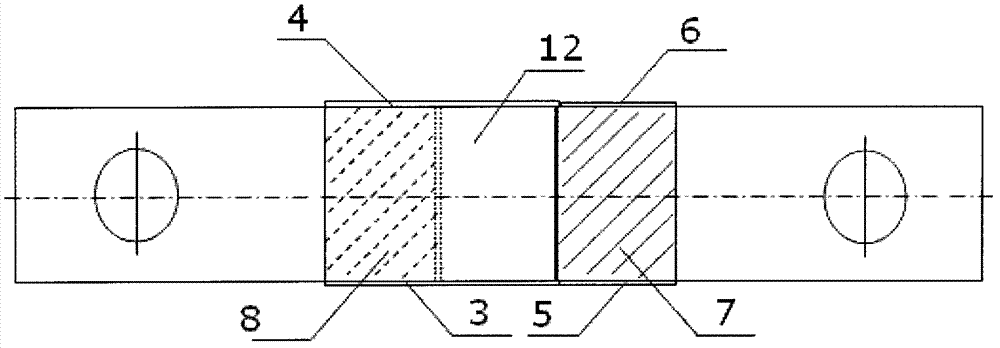

[0026] In order to further explain the technical means and effects of the present invention to achieve the intended purpose, the specific structure and effects of the present invention will be described in detail below in conjunction with the accompanying drawings, implementation methods, and structural features.

[0027] In the prior art, for heat-resistant coatings, the adhesion between the coating and the metal substrate is one of the performances that need to be investigated. At present, a large number of heat-resistant coatings for aerospace use organic resins as base materials, add fillers, and attach fiber cloth to reduce thermal conductivity and improve strength. The bonding performance test method between the heat-resistant coating and the metal substrate involved in the present invention is a tensile shear method.

[0028] The heat-resistant coating tensile shear strength test model of the present invention adopts a single lap joint form, and the specific structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com