Treatment method of metal surface

A technology of metal surface treatment and metal parts, which is applied in the field of metal surface treatment, can solve the problems of easy damage and poor bonding strength, and achieve the effects of avoiding pollution, good effect and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

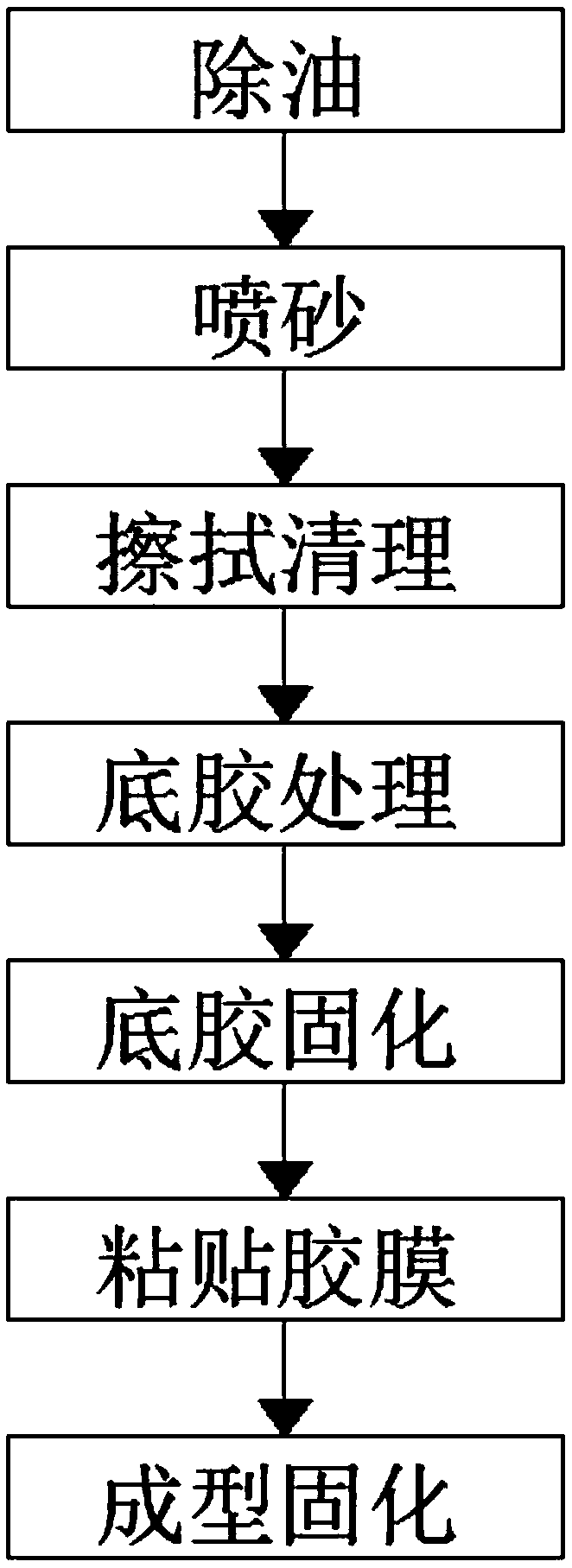

Image

Examples

Embodiment 1

[0040] The invention discloses a metal surface treatment method, the specific steps are as follows:

[0041] (1) Degreasing: Use a white cotton cloth to dip in the oil cleaning agent to wipe the oil on the surface of the metal parts;

[0042] (2) Sandblasting: Use paper tape to seal and isolate the non-adhesive surface of the metal parts, and then perform sandblasting, and use the impact of high-speed sand to clean and roughen the surface of the metal parts, so as to promote the roughening of the adhesive surface of the metal parts , increase the surface roughness of metal parts;

[0043] (3) Wipe and clean: Use a clean white cotton cloth dipped in oil cleaning agent to wipe the surface of the metal parts until the surface of the metal parts is completely clean. After cleaning, place it at room temperature for 1.5 hours;

[0044] (4) Primer treatment: Take out the primer from the -18°C cold storage, place it at room temperature for 7 hours before use, and then evenly apply a ...

Embodiment 2

[0056] The invention discloses a metal surface treatment method, the specific steps are as follows:

[0057] (1) Degreasing: Use a white cotton cloth to dip in the oil cleaning agent to wipe the oil on the surface of the metal parts;

[0058](2) Sandblasting: Use paper tape to seal and isolate the non-adhesive surface of the metal parts, and then perform sandblasting, and use the impact of high-speed sand to clean and roughen the surface of the metal parts, so as to promote the roughening of the adhesive surface of the metal parts , increase the surface roughness of metal parts;

[0059] (3) Wipe and clean: Use a clean white cotton cloth dipped in oil cleaning agent to wipe the surface of the metal parts until the surface of the metal parts is completely clean. After cleaning, place it at room temperature for 1.5 hours;

[0060] (4) Primer treatment: Take out the primer from the -18°C cold storage, place it at room temperature for 8 hours before use, and then evenly apply a 0...

Embodiment 3

[0072] The invention discloses a metal surface treatment method, the specific steps are as follows:

[0073] (1) Degreasing: Use a white cotton cloth to dip in the oil cleaning agent to wipe the oil on the surface of the metal parts;

[0074] (2) Sandblasting: Use paper tape to seal and isolate the non-adhesive surface of the metal parts, and then perform sandblasting, and use the impact of high-speed sand to clean and roughen the surface of the metal parts, so as to promote the roughening of the adhesive surface of the metal parts , increase the surface roughness of metal parts;

[0075] (3) Wipe and clean: Use a clean white cotton cloth dipped in oil cleaning agent to wipe the surface of the metal parts until the surface of the metal parts is completely clean. After cleaning, place it at room temperature for 1.5 hours;

[0076] (4) Primer treatment: Take out the primer from the -18°C cold storage, and place it at room temperature for 6.5 hours to use it, then apply a 0.15mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com