Cloth edge connecting machine

An edge machine and cloth technology, applied in the seams of textile materials, textiles and papermaking, etc., can solve the problems of increased thickness of cloth joints, failure of overlock sewing machines, and reduced processing efficiency, so as to reduce the waste cloth rate and improve Effects of improving productivity and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

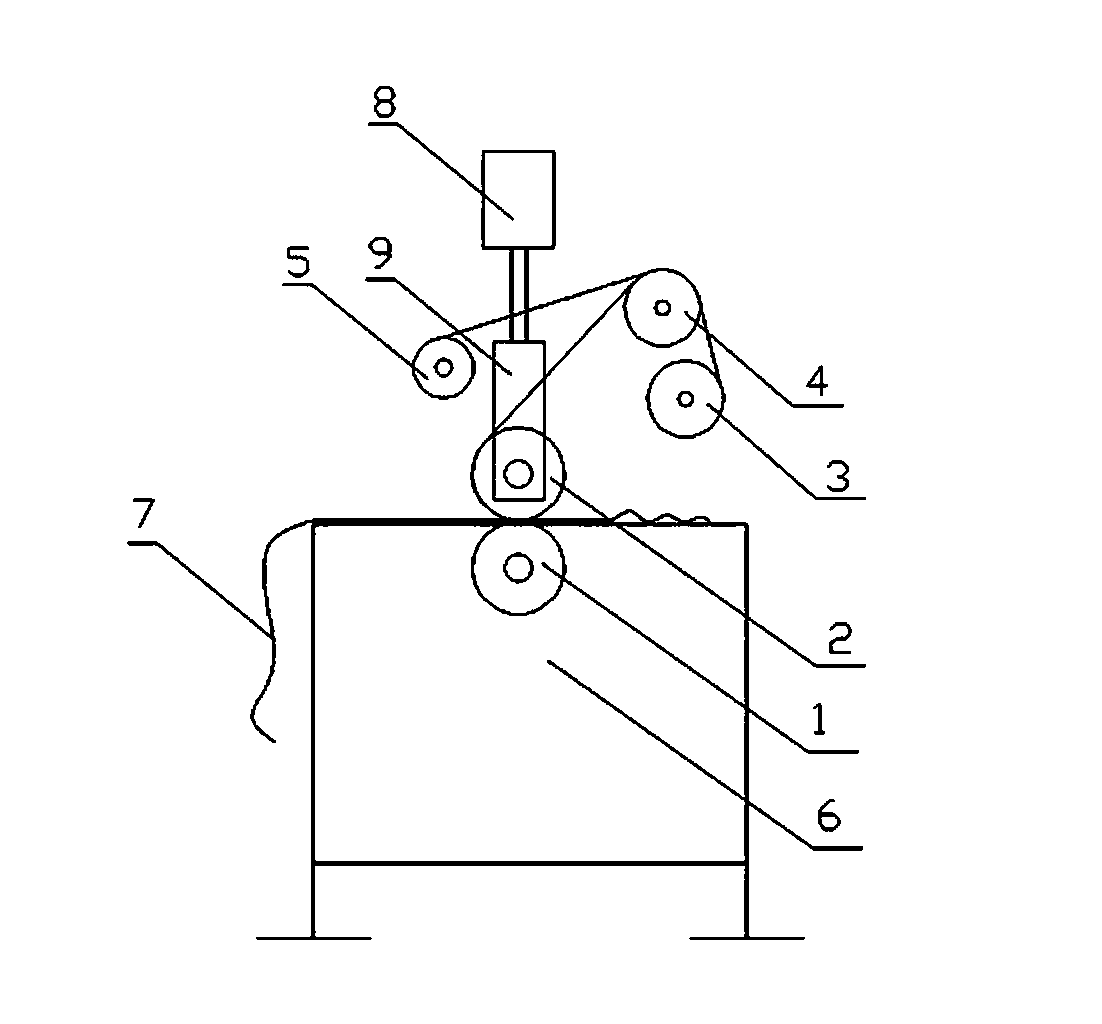

[0009] Embodiment: a kind of cloth bordering machine, comprises main driving wheel 1, pressing wheel 2, tape wheel 3, cloth belt wheel 4, tape collecting paper wheel 5, first, second driving device and frame 6, main driving wheel 1. The pressing wheel 2, the tape wheel 3, the cloth belt wheel 4 and the tape collecting wheel 5 are respectively rotatable and positioned on the frame 6. The first driving device drives the main transmission wheel 1 to rotate, and the outer surface of the pressing wheel 2 is tightened. Arriving at the outer side of the circumference of the main drive wheel 1, the double-sided tape is drawn from the tape wheel 3, and the side with glue is attached to the cloth belt on the cloth pulley 4, and the tape paper of the double-sided tape is wound on the tape receiving paper On the wheel 5, the second driving device drives the tape paper wheel to rotate, and the side of the cloth with double-sided adhesive tape is covered on the middle seam of the splicing cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com