Wood end sealing and cracking preventing method based on high molecular materials

A technology of polymer materials and wood, which is applied in the field of wood sealing and anti-cracking based on polymer materials, can solve problems such as low efficiency, easy cracking, and unsatisfactory anti-cracking effects, so as to improve work efficiency and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

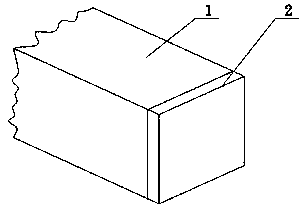

[0063] Embodiment 1: Taking high-strength polyurethane as an example, high-strength polyurethane is used to seal, attach and pin the end of the wood 1 as a whole or partly, and heat the high-strength polyurethane raw material above 60°C in an oven, and heat the polyurethane for 1 hour. Start to melt gradually and completely, use a coating tool to spread the melted polyurethane evenly on both ends of the wood 1, the thickness of the coating is about 2mm, and the high-strength polyurethane and wood 1 have good penetration and adhesion, and as the temperature decreases , the polymer material changes from fluid to solid. Due to the generation of van der Waals force or chemical bond force during the period, a high-strength coating layer 2 is formed at the end of the wood 1, which not only plays a sealing role but also prevents the wood 1 from being processed, stored, and transported. The role of link cracking, so as to effectively prevent the veneer from cracking after the wood is s...

Embodiment 2

[0064] Embodiment 2: Taking high-density polyethylene as an example, high-density polyethylene is used to seal the whole or part of the end of wood 1. Technological wood is also called artificial wood. A large amount of internal stress will be generated in the later stage of processing, and the process of stress release will cause Cracking, sawing, planing, cutting and rotary cutting will also produce a large number of cracks, which will affect the utilization rate and quality. After the hot press is ready, put the high-density polyethylene into the prepared position, and perform hot pressing operations on both ends of the wood 1 respectively. The high-density polyethylene changes from a solid to a flowable fluid, which is pressed to the end of the wood 1 by a hot press, and the polymer material and the wood 1 have good penetration and adhesion. As the temperature decreases, the high The molecular material changes from fluid to solid, and due to the generation of van der Waals ...

Embodiment 3

[0065] Embodiment 3: Taking high-toughness epoxy resin as an example, high-toughness epoxy resin is used to seal the whole or part of the end of wood 1, attach and pin it down, and cure high-toughness epoxy resin and epoxy resin that are paste-like at room temperature The agent is stirred evenly by a mixer in the packaging barrel, and the evenly stirred high-toughness epoxy resin is evenly applied to both ends of the wood 1 with a coating tool. Penetration, resulting in adhesion, with the self-reaction of the two-component high-toughness epoxy resin, the high-toughness epoxy resin changes from the paste to the solid through the process of cross-linking and curing, due to the generation of van der Waals force or chemical bond force during the period, A high-strength coating layer 2 is formed at the end of the wood 1, which not only plays a sealing role but also plays a role in preventing the wood 1 from cracking during processing, storage and transportation, so as to effectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com