Masking paper adhesive tape and preparation method thereof

A technology of masking paper and adhesive tape, applied in the direction of adhesives, rubber derivatives, adhesive types, etc., can solve the problems of low initial tack, low viscosity of pressure-sensitive adhesive systems, poor flexibility, etc., to improve stickiness and initial tack , excellent low temperature softness, good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

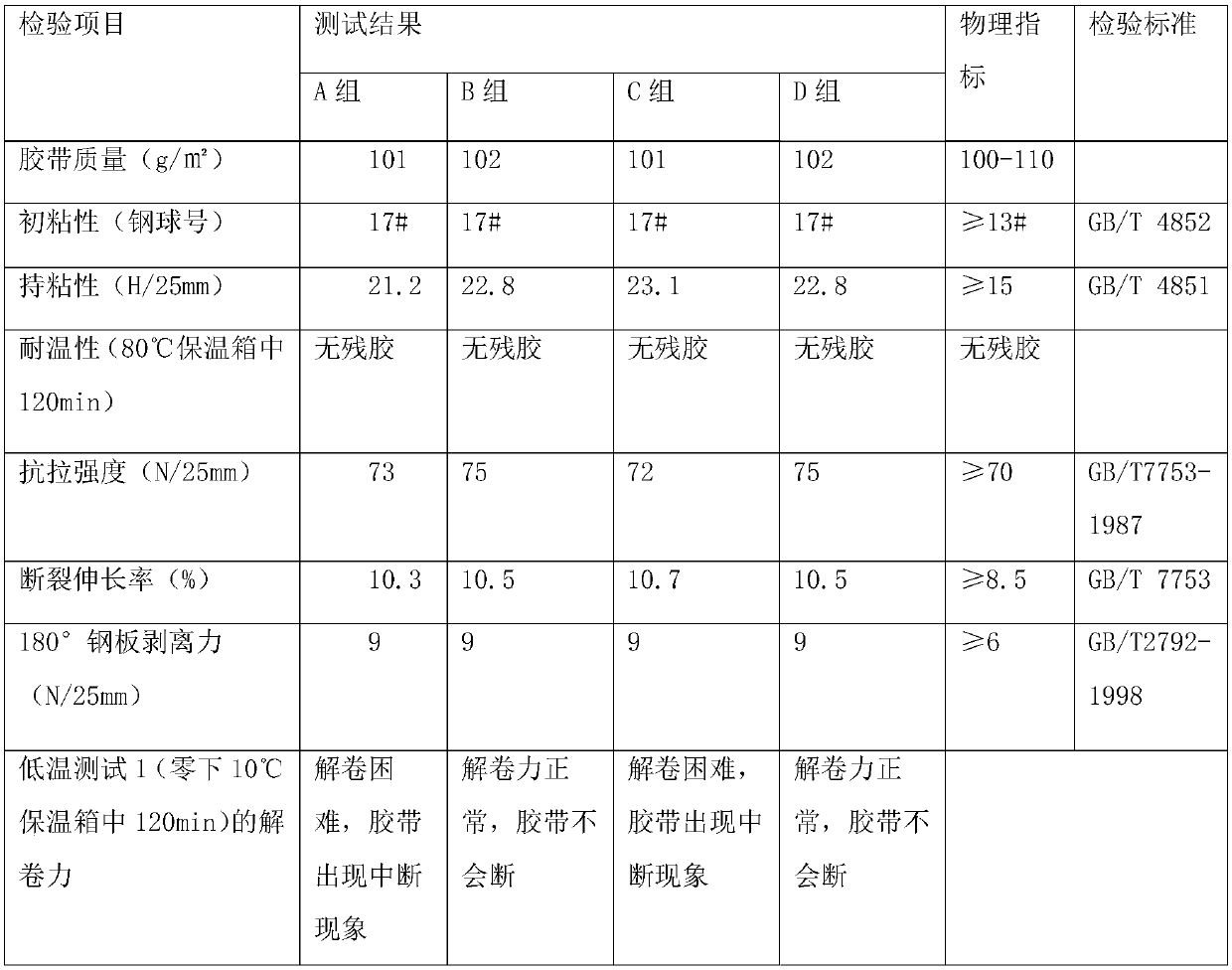

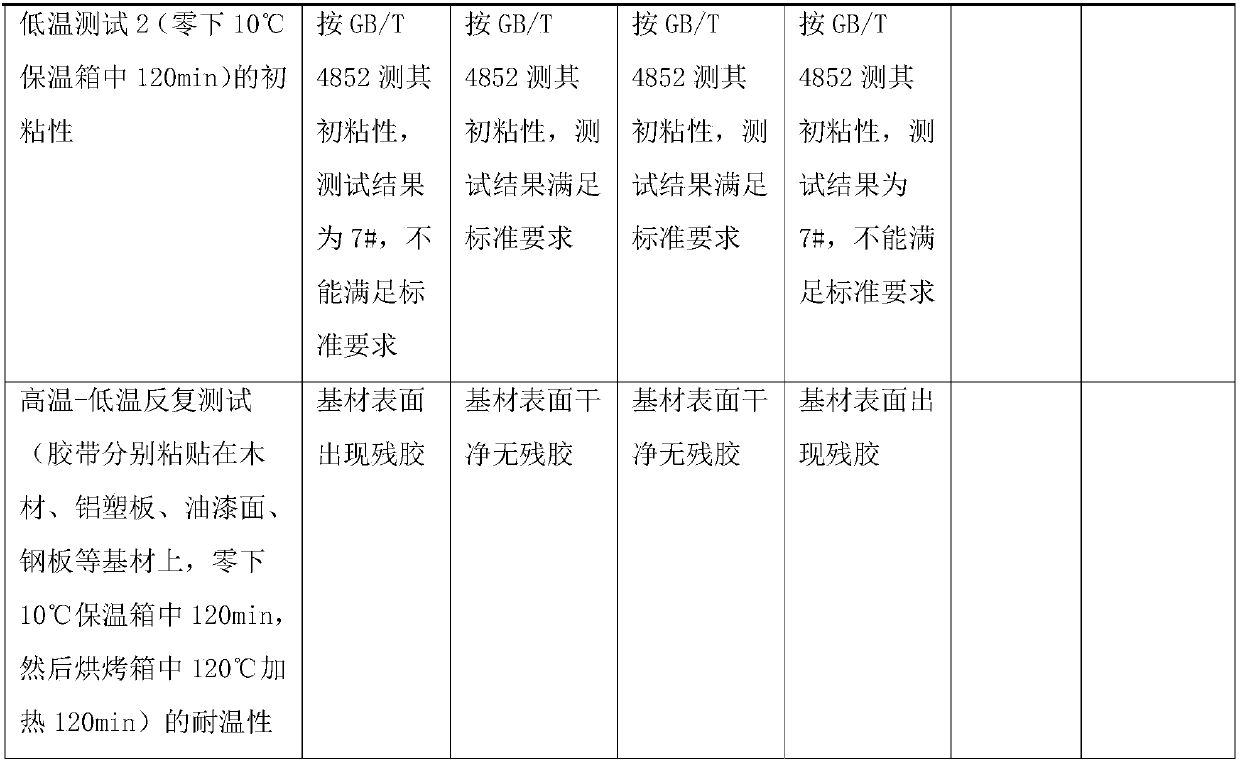

Examples

Embodiment 1

[0031] A kind of textured paper tape, it comprises textured paper substrate and is arranged on the waterproof agent and pressure-sensitive adhesive on described textured paper substrate, and described pressure-sensitive adhesive is made of organosilicon modified rubber (organosilicon modified natural Rubber, silicone modified nitrile rubber, silicone modified EPDM rubber), solvent (xylene, toluene, petroleum ether), tackifying resin (epoxy resin, epoxy modified phenolic resin, petroleum resin, terpene ethylene resin, rosin resin, hydrogenated rosin resin), plasticizer (diisononyl cyclohexane 1,2-dicarboxylate, acetyl tributyl citrate), silane coupling agent (3-aminopropyl tri Ethoxysilane, γ-(methacryloyloxy)propyltrimethoxysilane, γ-mercaptopropyltrimethoxysilane) and fillers (nano-silica, nano-calcium carbonate, talc).

[0032] The preparation method of the masking tape of present embodiment 1, its operation steps are:

[0033] S1. Put the masking paper base material in the...

Embodiment 2

[0044] A kind of textured paper tape, it comprises textured paper substrate and is arranged on the waterproof agent and pressure-sensitive adhesive on described textured paper substrate, and described pressure-sensitive adhesive is made of organosilicon modified rubber (organosilicon modified natural Rubber, silicone modified nitrile rubber, silicone modified EPDM rubber), solvent (xylene, toluene, petroleum ether), tackifying resin (epoxy resin, epoxy modified phenolic resin, petroleum resin, terpene ethylene resin, rosin resin, hydrogenated rosin resin), plasticizer (diisononyl cyclohexane 1,2-dicarboxylate, acetyl tributyl citrate), silane coupling agent (3-aminopropyl tri Ethoxysilane, γ-(methacryloyloxy)propyltrimethoxysilane, γ-mercaptopropyltrimethoxysilane) and fillers (nano-silica, nano-calcium carbonate, talc).

[0045] The preparation method of the masking tape of present embodiment 2, its operation steps are:

[0046] S1. Spray a release agent on one surface of th...

Embodiment 3

[0055] A kind of textured paper tape, it comprises textured paper substrate and is arranged on the waterproof agent and pressure-sensitive adhesive on described textured paper substrate, and described pressure-sensitive adhesive is made of organosilicon modified rubber (organosilicon modified natural Rubber, silicone modified nitrile rubber, silicone modified EPDM rubber), solvent (xylene, toluene, petroleum ether), tackifying resin (epoxy resin, epoxy modified phenolic resin, petroleum resin, terpene ethylene resin, rosin resin, hydrogenated rosin resin), plasticizer (diisononyl cyclohexane 1,2-dicarboxylate, acetyl tributyl citrate), silane coupling agent (3-aminopropyl tri Ethoxysilane, γ-(methacryloyloxy)propyltrimethoxysilane, γ-mercaptopropyltrimethoxysilane) and fillers (nano-silica, nano-calcium carbonate, talc).

[0056] The preparation method of the masking tape of present embodiment 1, its operation steps are:

[0057] S1. Put the masking paper base material in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com