Vamp wrapping process for carbon fiber prepreg repaired aluminum alloy crack pipe

A carbon fiber prepreg, aluminum alloy tube technology, applied in the field of composite materials, can solve the problems of the immature wrapping process of composite materials repairing aluminum alloy cracked tubes, and the lack of research on composite materials repairing aluminum alloy cracked tubes, so as to improve the bearing capacity and avoid cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

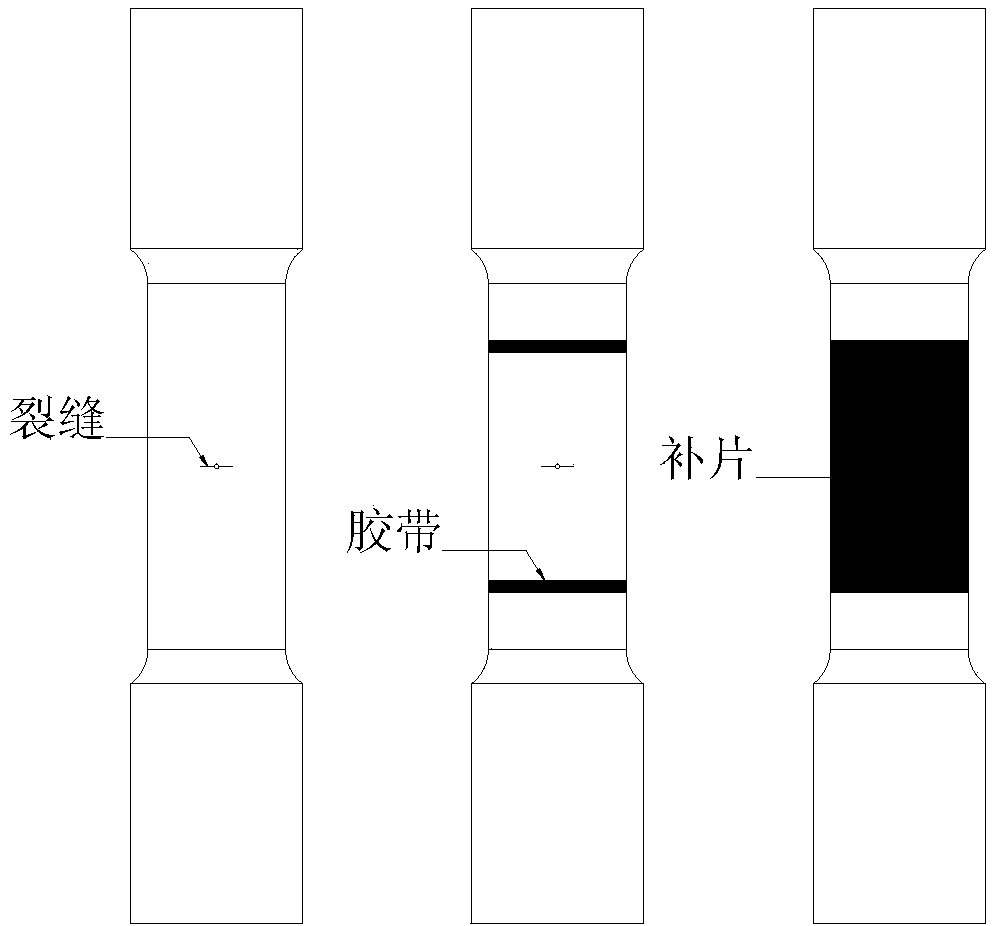

[0021] The present invention finally obtains the repair component (such as image 3 ), including positioning, gluing, winding and curing four steps, the specific process is as follows.

[0022] (1) Positioning, take the crack of the aluminum alloy tube as the symmetrical point, and paste the common adhesive tape (clear tape, etc.) on both ends of the crack of the aluminum alloy tube symmetrically. The inner distance between the two adhesive tapes is 100mm. (that is, the length of the patch) is 100mm, the repair effect of the patch is the best;

[0023] (2) gluing, mixing acetone and epoxy resin with a volume ratio of 1:1 to obtain epoxy resin glue, and smearing the prepared epoxy resin glue between the two adhesive tapes evenly;

[0024] (3) Winding, the prepared patch is wound between two adhesive tapes, and the lap length is 1mm;

[0025] (4) Curing. Heat and cure the wrapped components. The curing system is 80°C / 1h+130°C / 1h. The reason for choosing the above curing system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com