A coplanar mechanism and its control system for laser guidance

A coplanar mechanism, laser-guided technology, used in therapy, radiation therapy, X-ray/γ-ray/particle irradiation therapy, etc., can solve the problems of inapplicable accuracy requirements, large components, easy to cause errors, etc. The effect of comprehensive angle, accurate range of motion and avoiding movement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

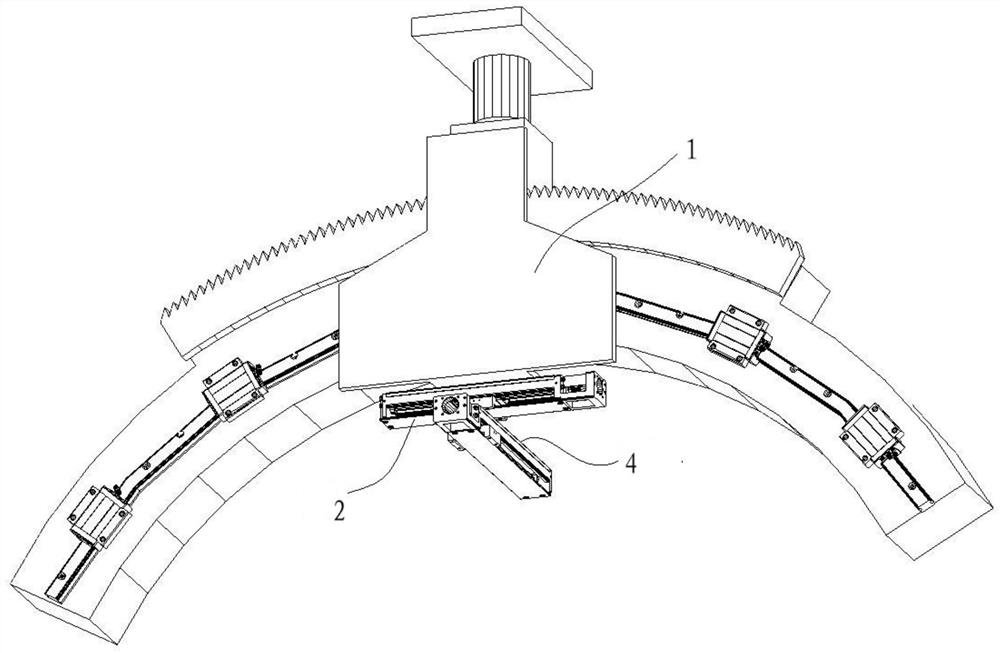

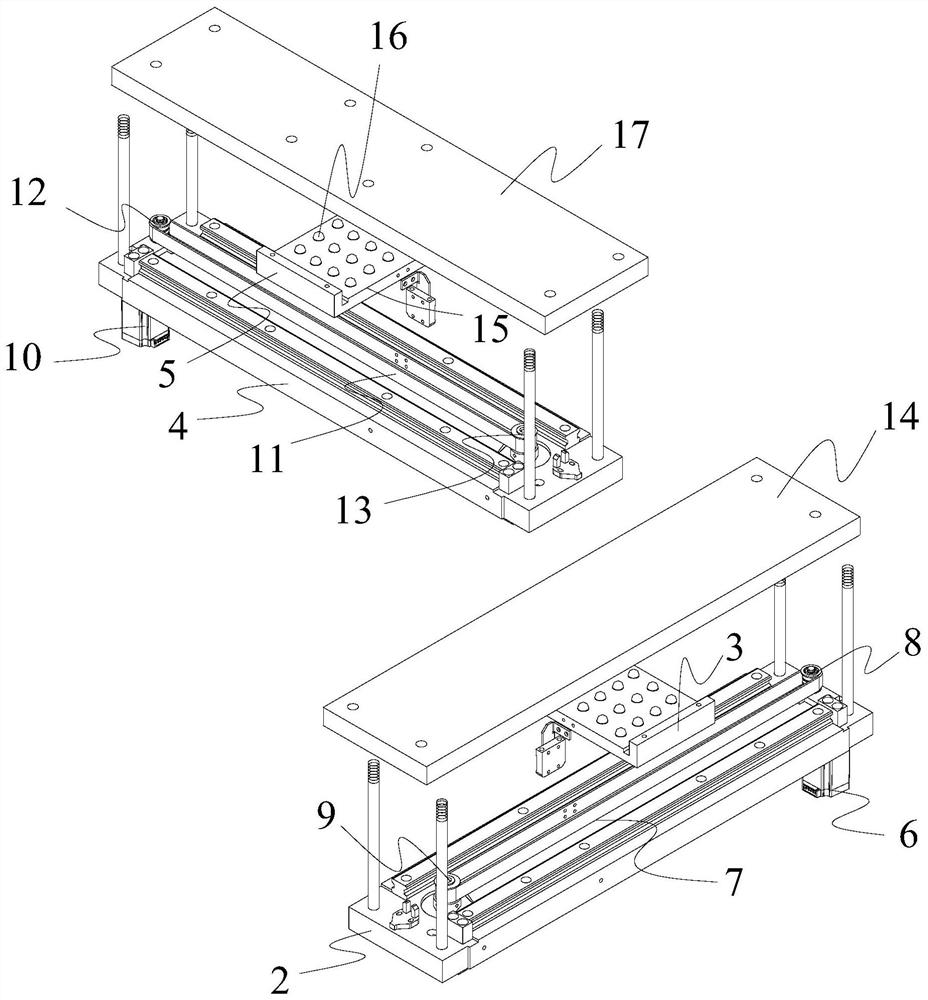

[0031] like figure 1 As shown, a coplanar mechanism for laser guidance includes a laser track device 1 and a first sliding arm and a second sliding arm arranged at the bottom of the laser track device 1. The first sliding arm includes a The first casing 2 at the bottom of the device 1 and the first slide rail mechanism arranged on the first casing 2, the first slide rail mechanism is connected with the first slider 3, the bottom of the first slider 3 and the second The second casing 4 of the sliding arm is connected, and the first sliding rail mechanism drives the second sliding arm to move left and right below the first sliding arm through a slider; the second casing 4 is provided with a second sliding rail mechanism, and the The second slide rail mechanism is connected with a second slide block 5, the bottom of the second slide block 5 is used to connect the laser emitting head, and the second slide rail mechanism drives the laser emitting head to slide in the second The bo...

Embodiment 2

[0033] like figure 1 , figure 2 As shown, on the basis of the above embodiment, as a preferred solution, the first slide rail mechanism includes a first servo motor 6 and a first transmission belt 7, and the first servo motor 6 is vertically arranged on the At one end, the rotating shaft of the first servo motor 6 is connected with a first driving gear shaft 8, and the other end of the first housing 2 is connected with a first driven gear shaft 9, and the first driving gear shaft 8 and the first slave gear shaft 8 are connected with each other. A first transmission belt 7 is connected between the movable pinion shafts 9, and the top of the first slider 3 is connected on the first transmission belt 7; the second slide mechanism includes a second servo motor 10 and a second transmission belt 11, and the first Two servo motors 10 are vertically arranged at two ends of the second housing 4, the second driving gear shaft 12 is connected to the rotating shaft of the second servo m...

Embodiment 3

[0035] like figure 1 , figure 2 As shown, on the basis of the above embodiments, as a preferred solution, the sliding direction of the first slide rail mechanism and the sliding direction of the second slide rail mechanism are perpendicular to each other, that is, the Cartesian coordinate system of the X-axis and Y-axis constituting the plane , so that the points below the coplanar mechanism and the points coplanar with the coplanar mechanism can be marked in the Cartesian coordinate system to facilitate the positioning of the points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com