Label feeder

A label feeding and labeling machine technology, which is applied in cloth feeding mechanism, sewing machine components, textiles and paper making, etc., can solve the problems of inability to meet large-scale mass production, high labor intensity of workers, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described below in conjunction with accompanying drawing.

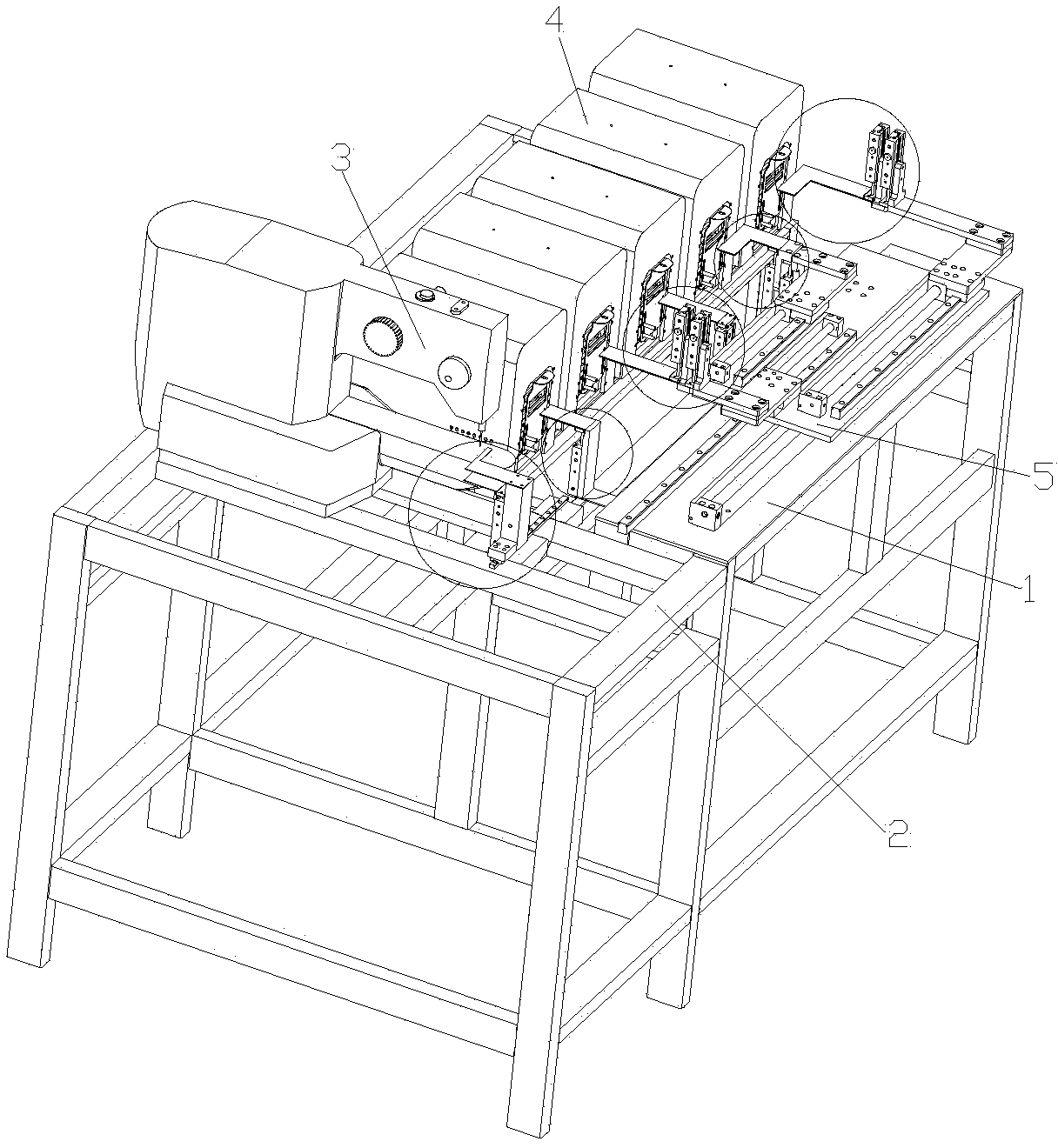

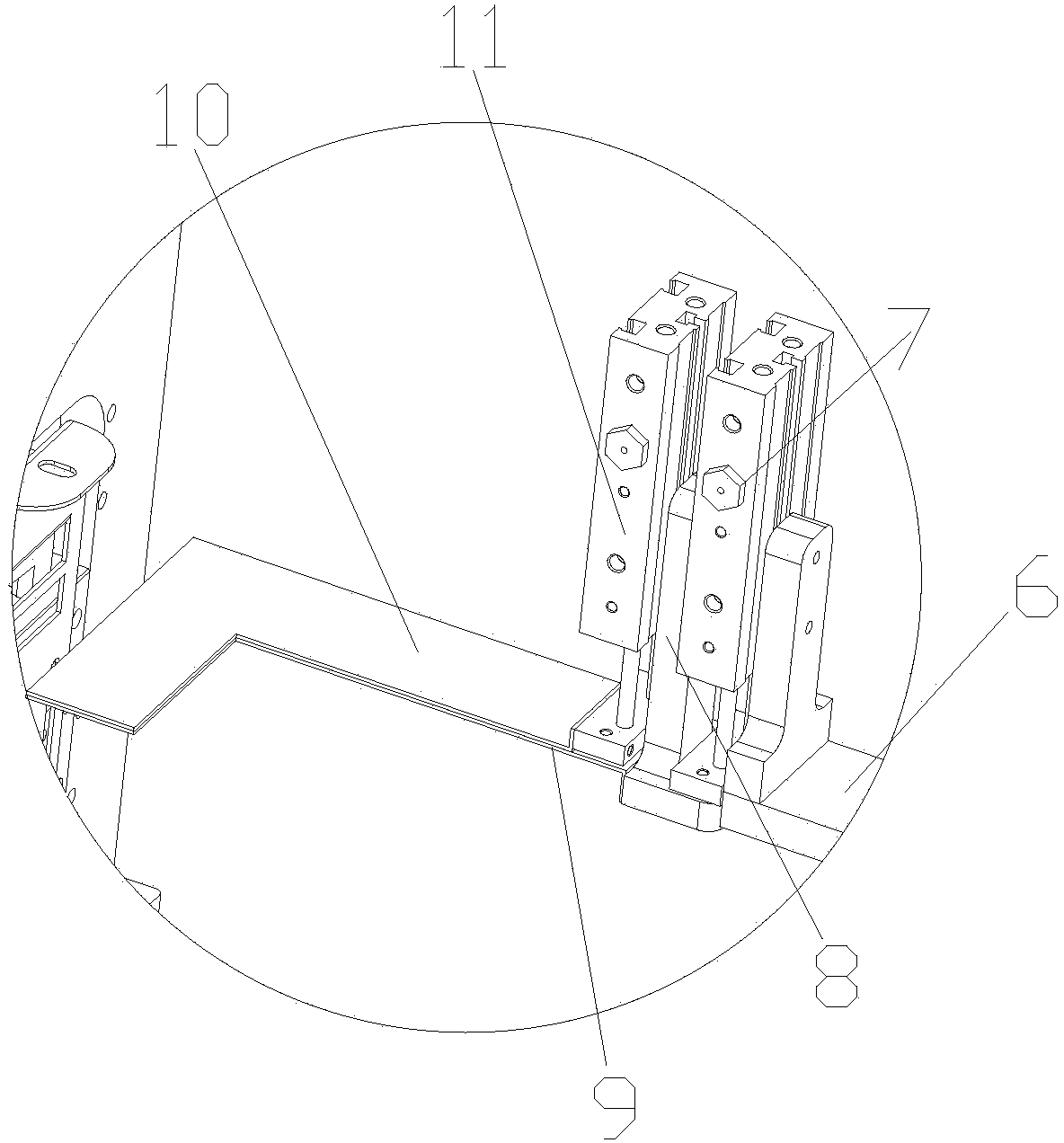

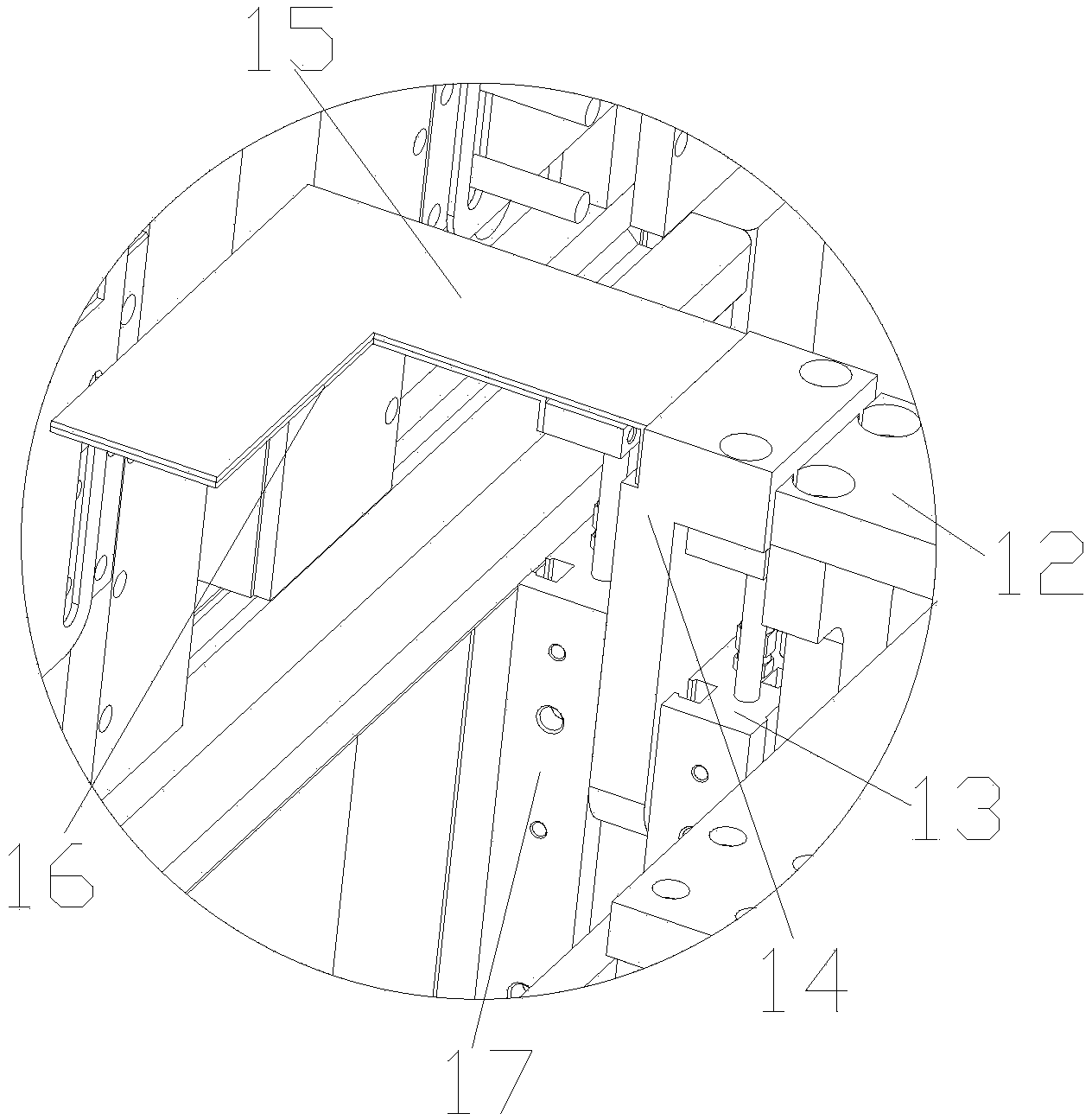

[0027] as attached Figure 1-8The shown a kind of marking machine of the present invention, comprises the cutting device and the integration device that are fixed on the first machine platform 1, the sewing machine 3 and the conveying device that are fixed on the second machine platform 2; The cutting device and the integrating device are correspondingly arranged on both sides of the first machine table; the conveying device is located on one side of the sewing machine; the cutting device cuts off a plurality of labels respectively; The labels are integrated together; the conveying device transmits the integrated multiple labels to the sewing machine for sewing; the shearing device includes five label cutting machines 4 fixed on the first machine in turn; the five The label shearing machines 4 are distributed in a linear array; the integration device includes a first clamping mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com