Full automatic edge cutting and edge seaming machine for cloth

A fully automatic, hemming machine technology, applied in the direction of cloth feeding mechanism, sewing machine components, sewing equipment, etc., can solve the problems of low production efficiency, high labor intensity, poor quality of hemming, etc., achieve high production efficiency and reduce labor intensity , Good quality effect of wrapping edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

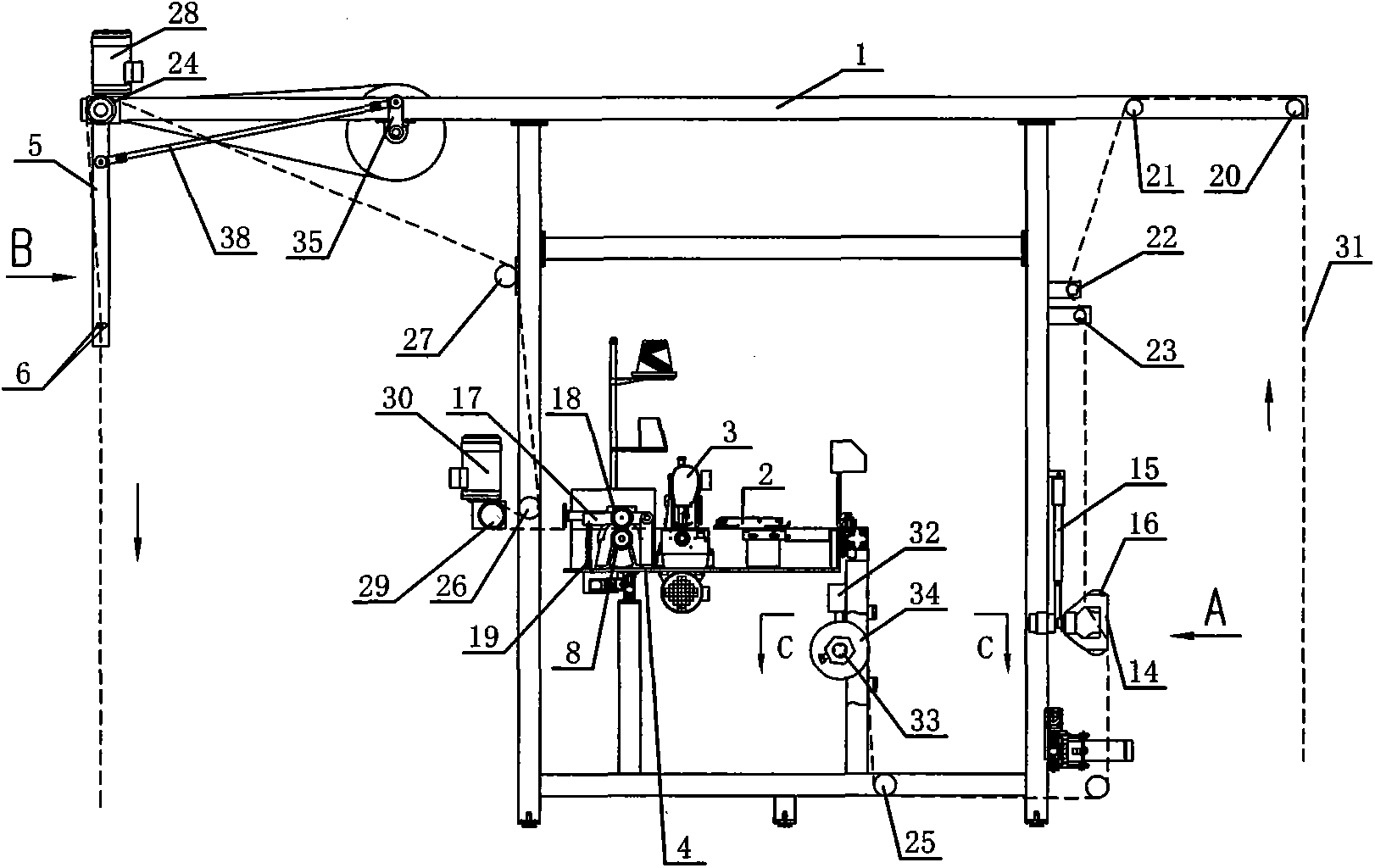

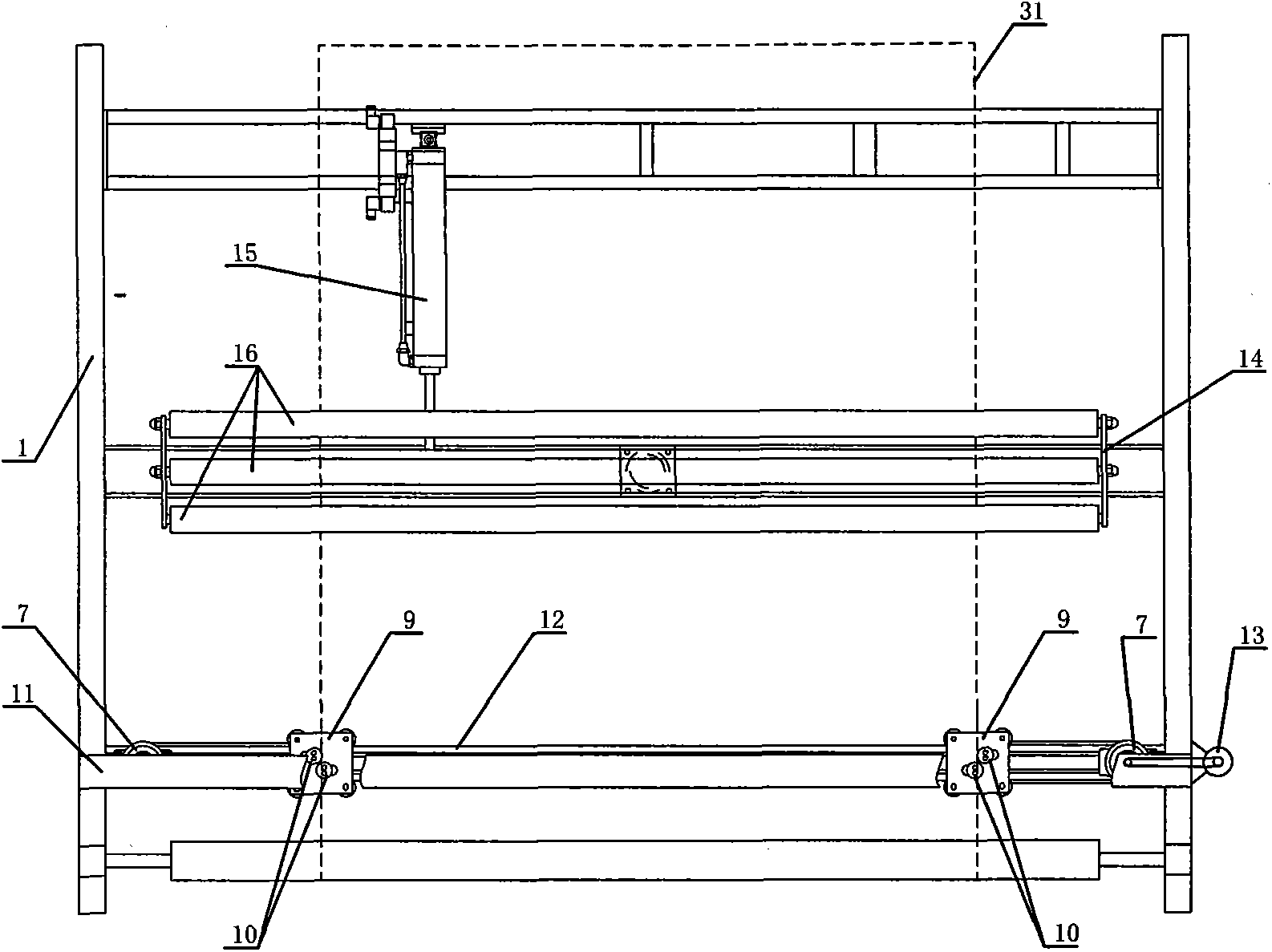

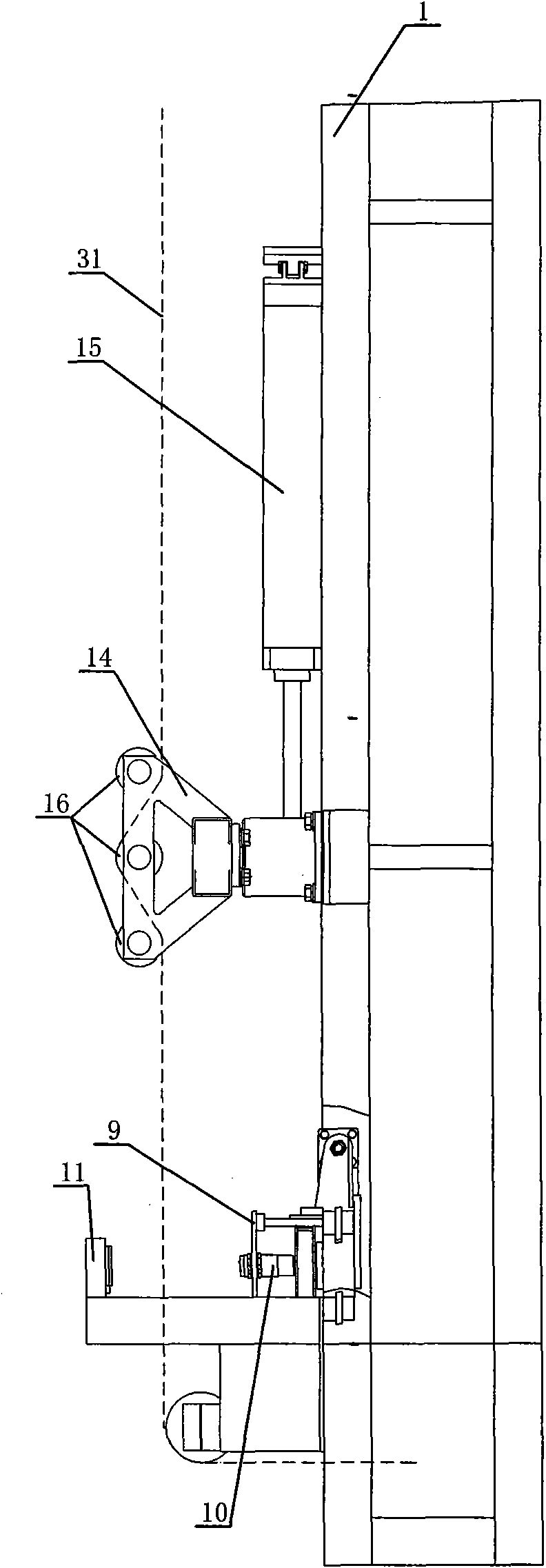

[0019] The present invention distinguishes the front and back according to the direction of the cloth, with the direction of the cloth entering as the front and the direction of the cloth exiting as the rear, the direction of the cloth 31 is as follows: figure 1 Shown in the middle arrow, the cloth 31 shown in the figure is a dotted line. Such as figure 1 As shown, the cloth automatic edge trimming and sewing machine includes a frame 1, and the frame 1 is provided with a cloth input guide roller group and a cloth output guide roller group in sequence according to the direction of the cloth. The support plate 4 between the guide roller group and the cloth outlet guide roller group, the automatic flanging device 2 and the automatic sewing machine 3 are arranged on the support plate 4 according to the cloth direction from front to back, the automatic flanging device 2 and the automatic sewing machine The structure of the machine 3 is all prior art, and will not be repeated here;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com