Full-automatic button stay sewing machines

A sewing machine and fully automatic technology, which is applied in the field of sewing machines, can solve the problems of slow manual sewing speed and unstable process quality, and achieve the effect of saving manpower and material resources, neat and beautiful cuts on the placket, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

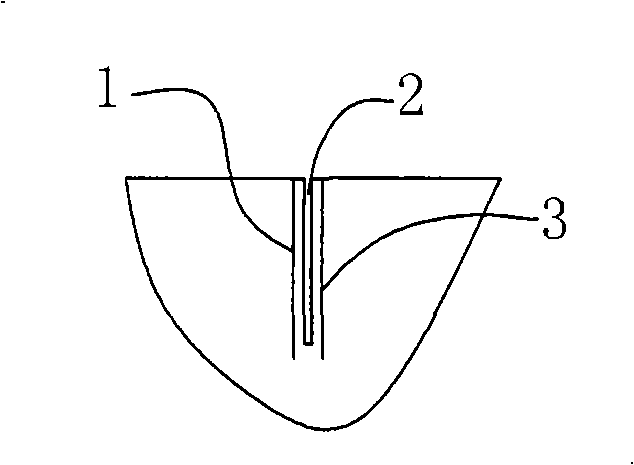

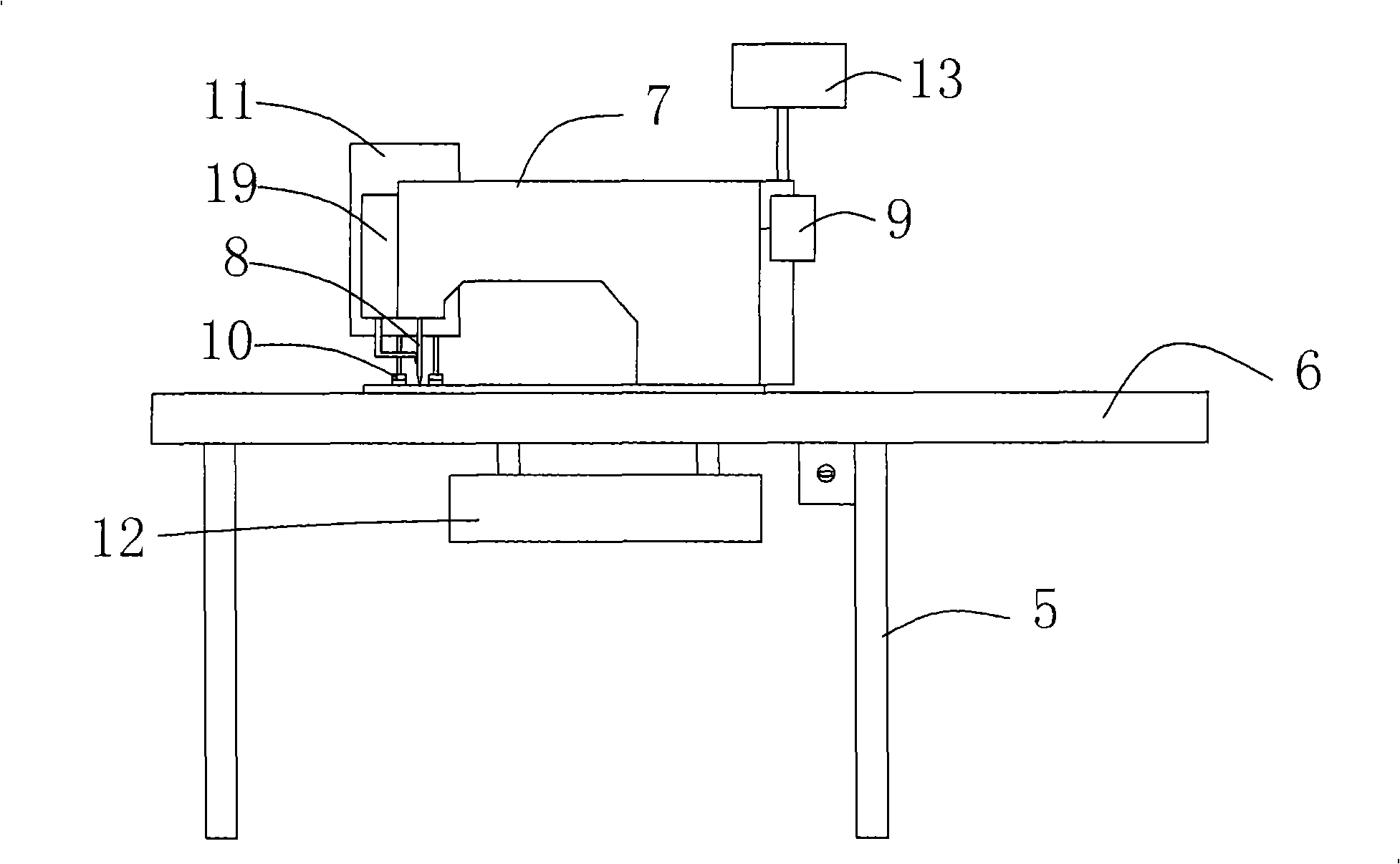

[0025] The fully automatic placket sewing machine of the present invention will be further described below in conjunction with accompanying drawings and specific embodiments:

[0026] The full-automatic placket sewing machine of the present invention is researched and developed by referring to the existing double-needle placket sewing machine, combining the flexibility of hand-sewing the placket with a common single-needle sewing machine, and combining the advantages of both. The placket sewing machine of the present invention has the following structural parts of the existing double-needle placket sewing machine, as attached figure 2 As shown, the frame 5, the worktable 6, the machine head 7 fixed on the upper part of the frame 5, the sewing machine needle 8 and the sewing machine needle driving mechanism 9 are installed on the machine head, and the driving mechanism 9 drives the sewing machine needle 8 to reciprocate up and down with the sewing thread , The head 7 rear port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com