Pocket-hole sewing machine for clothing pocket mouth processing

A bag opening machine and clothing technology, applied in cloth feeding mechanism, sewing machine components, textiles and paper making, etc., can solve the problems of inability to complete mechanized processing, complete a single step, low processing efficiency, etc., achieve high production efficiency and reduce the number of workers , The effect of high bag opening accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

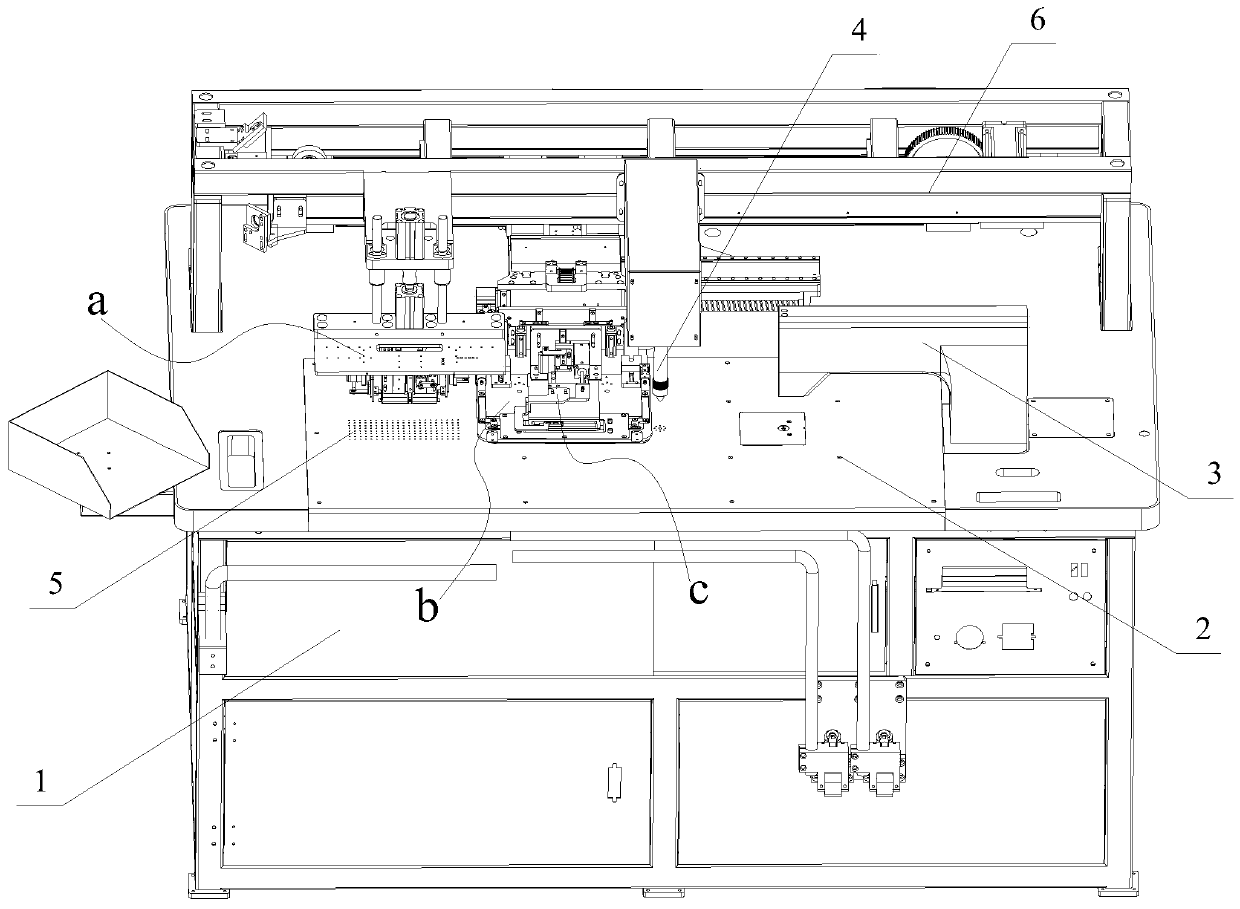

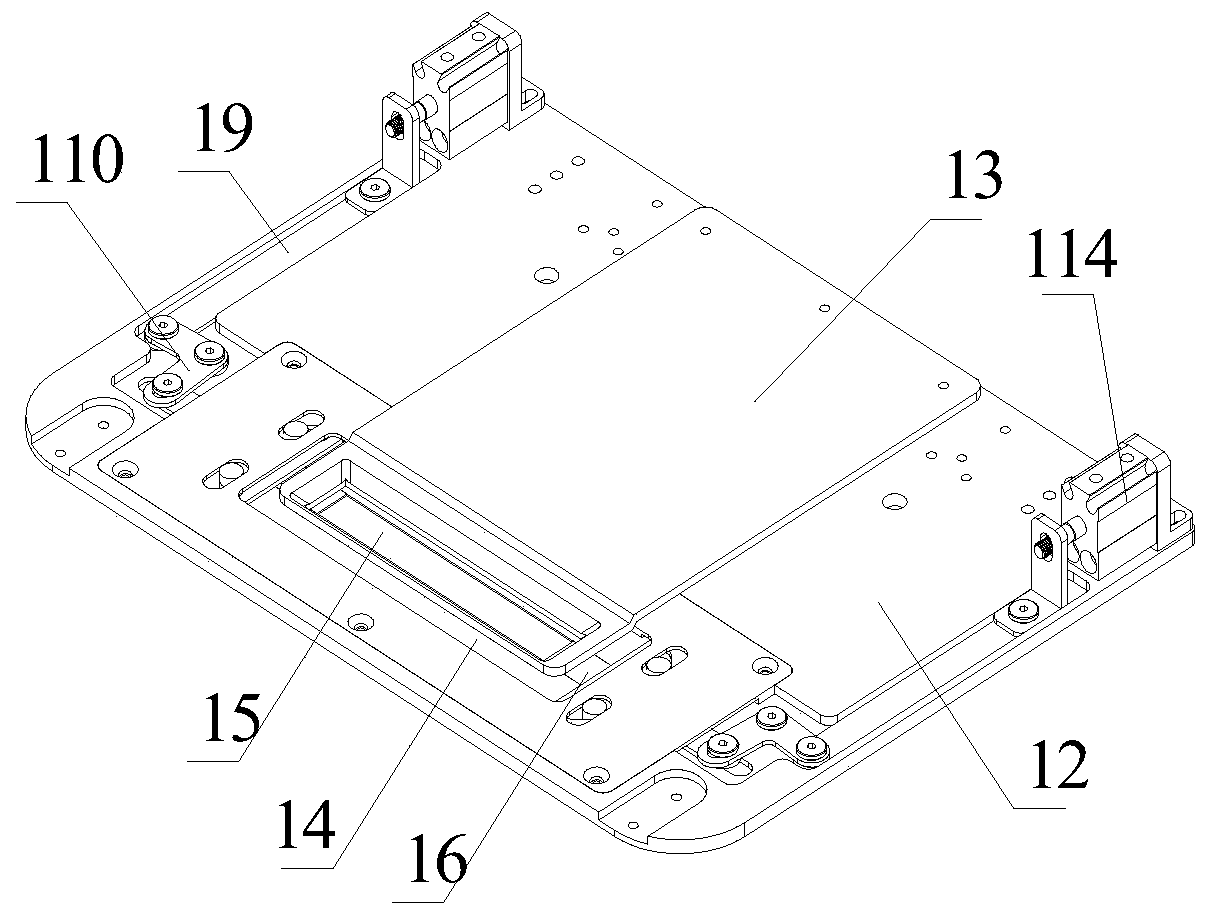

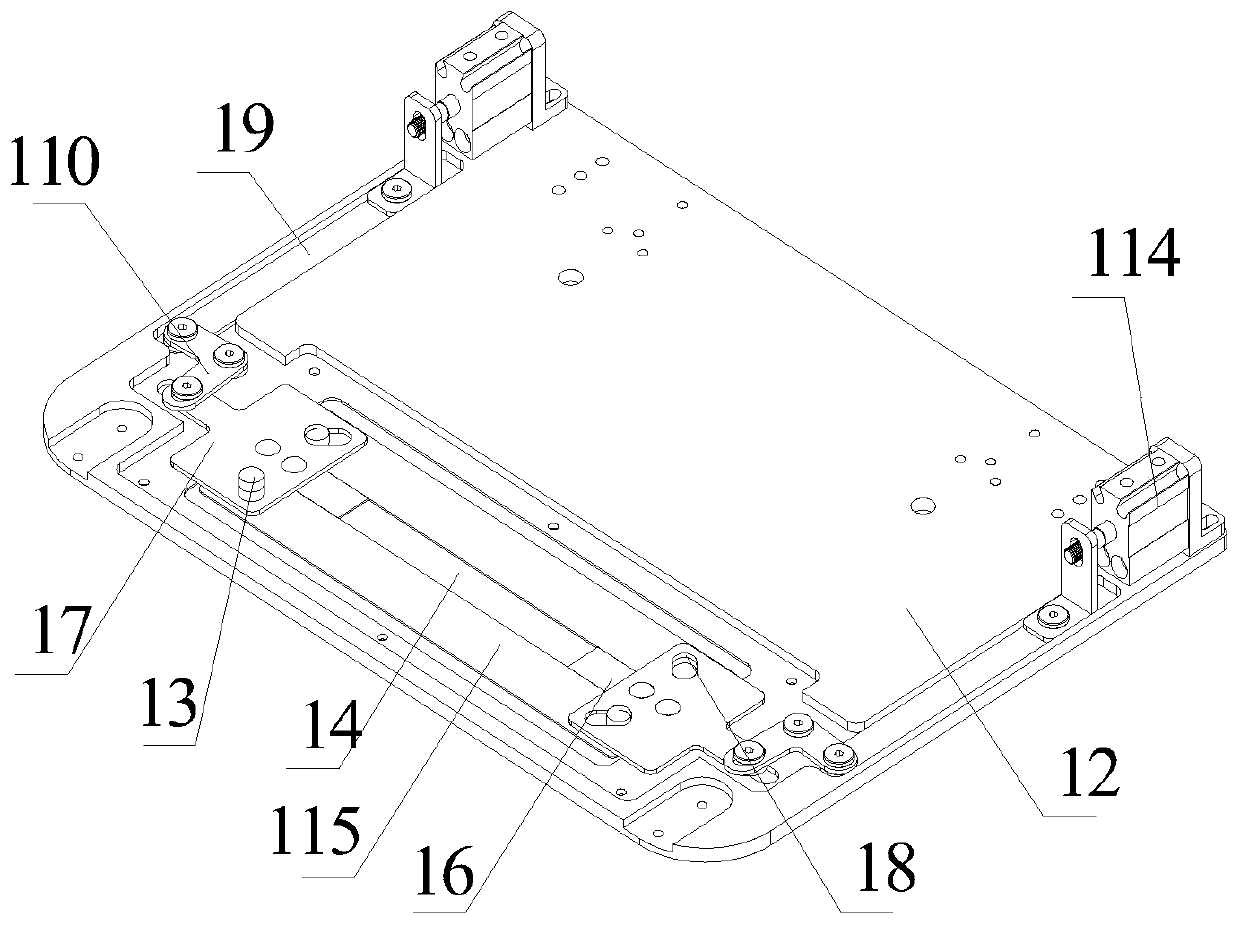

[0027] refer to Figure 1 to Figure 6 , the present invention includes a workbench 2 fixed on the frame 1 and a sewing machine 3 arranged on the workbench 2, a laser tube 4 for cutting the mouth of the bag is arranged above the workbench 1, and a laser tube 4 is arranged on the workbench 1 A discharge opening 5 for placing the lip of the bag is provided, and an upper beam 6 is horizontally provided above the workbench 1, and the laser tube 4 is fixed on the upper beam 6, and is located between the sewing machine 3 and the discharge opening 5. A negative pressure device is installed on the port 5, so that the discharge port 5 can absorb the lip of the bag;

[0028]The upper crossbeam 6 is provided with a bag folding mechanism a above the discharge port 5. The bag folding mechanism a is used to fold the cut garment pocket. The bag folding mechanism a does not move, and the bag folding mechanism a does not move. It can be directly fixed on the workbench 1. In this embodiment, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com