Thread cutting mechanism in sewing machine

A thread cutting mechanism and sewing machine technology, applied to the thread cutting mechanism in the sewing machine, sewing machine components, sewing machine control devices, etc., can solve the problems of waste materials that cannot be absorbed, processed in time, and waste accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

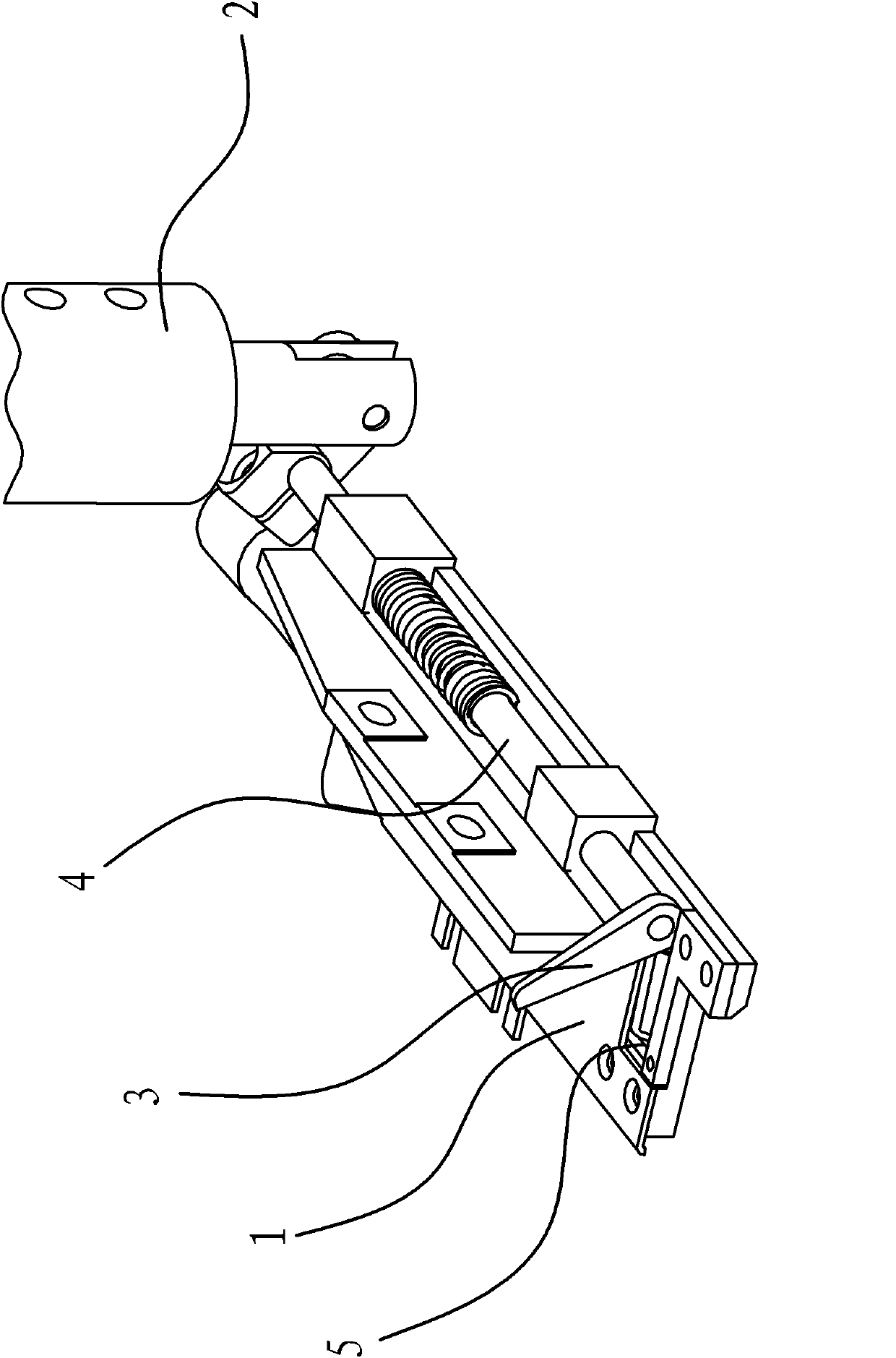

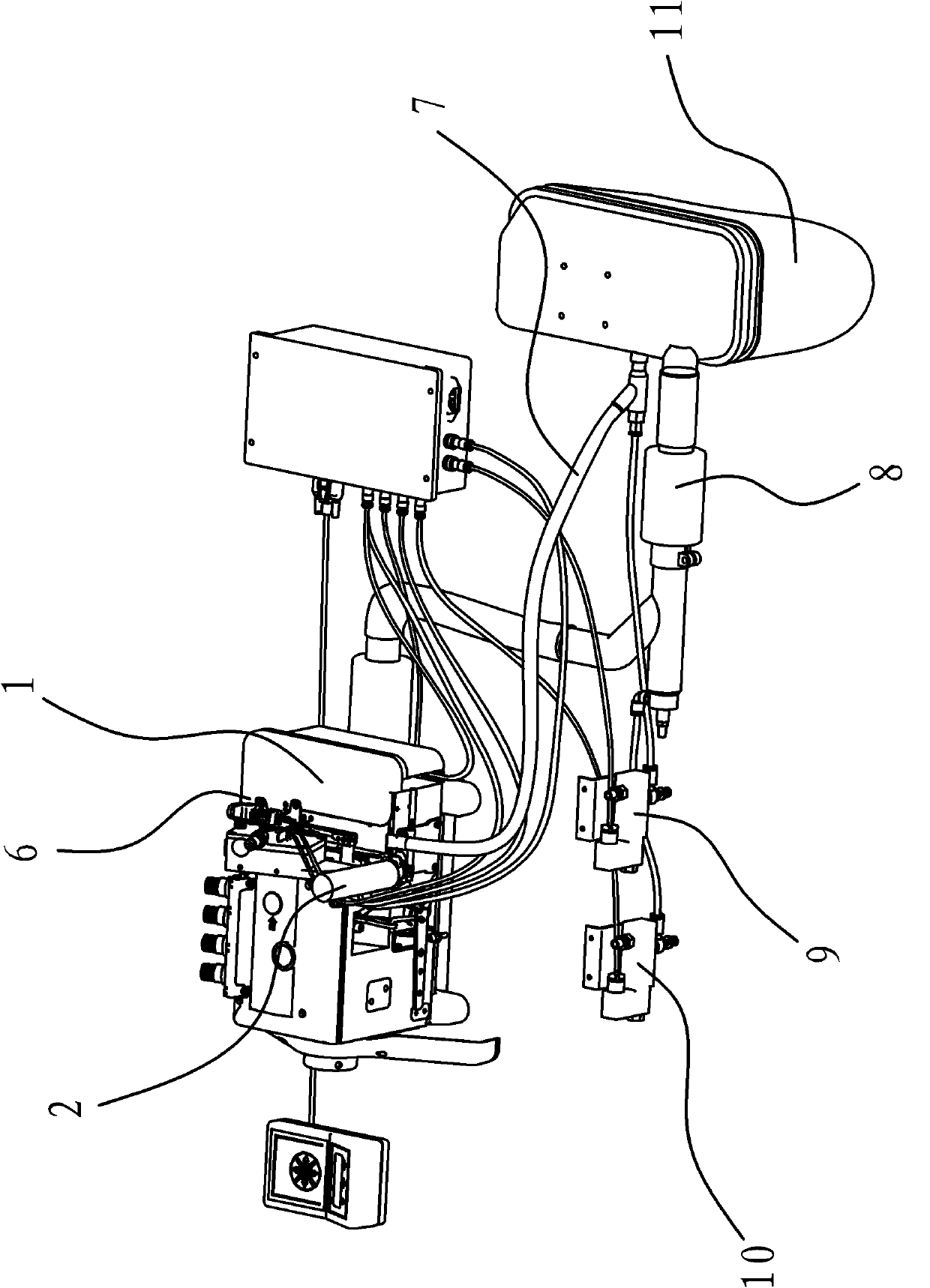

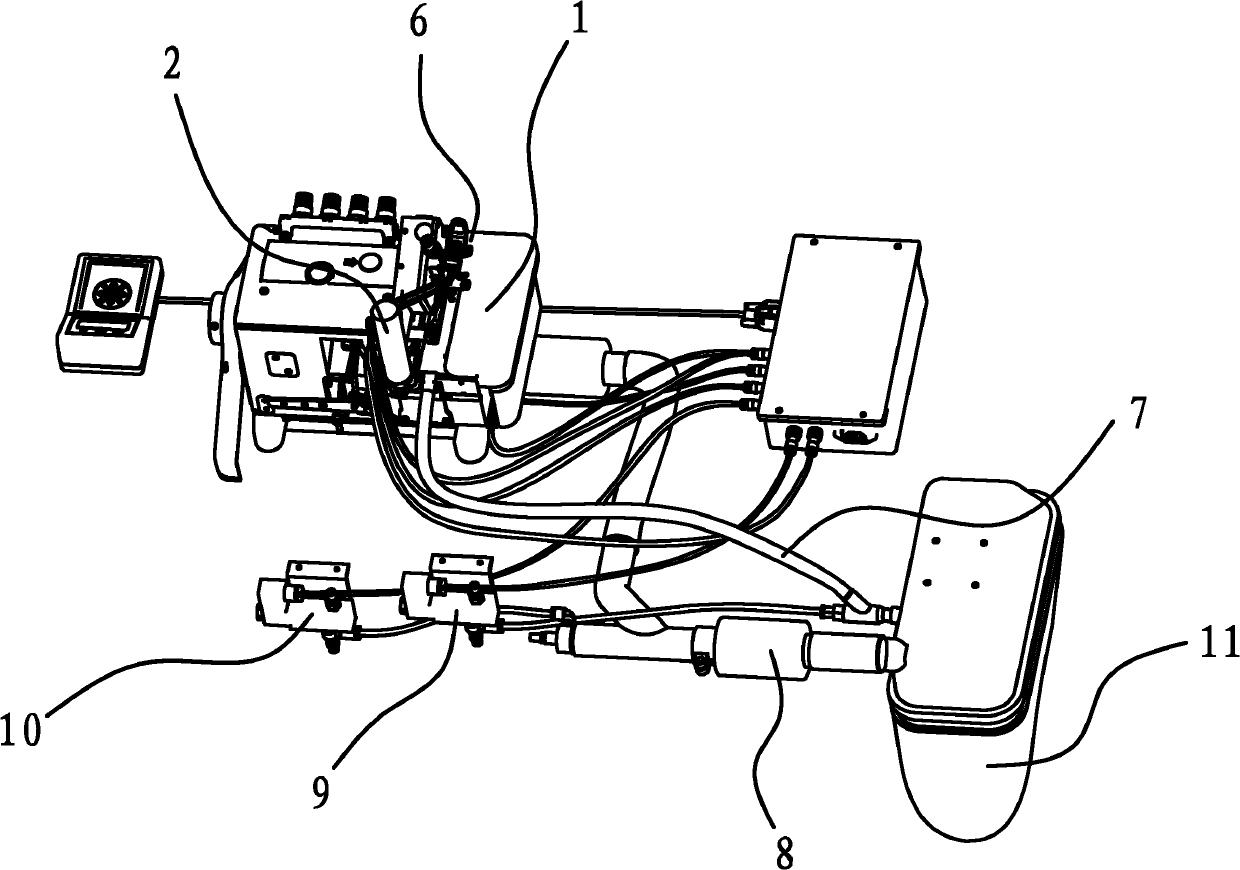

[0036] like figure 1 As shown, the thread trimming mechanism in this sewing machine is arranged at the needle plate 1 place of the sewing machine. It includes a driving part 2 and a cutting knife 3 for thread trimming. The driving part 2 is an electromagnet. A pendulum shaft 4 is fixed axially on the needle plate 1. One end of the pendulum shaft 4 is hinged to the iron core of the above-mentioned electromagnet. The cutting knife 3 is fixedly connected to the other end of the balance shaft 4.

[0037] like figure 1 and figure 2 As shown, there is an air suction port 1 on the needle plate 1 corresponding to the cutter 3, and there is an air suction port 2 6 at the feeding place of the needle plate 1. Connected pumping components.

[0038] The pump suction assembly includes a pipeline one 7 and a pipeline two 8, the pipeline one 7 has a solenoid valve one 9, the pipeline two 8 has a solenoid valve two 10, and the two ends of the pipeline one 7 are respectively connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com